The P0329 code stands for "Knock/Combustion Vibration Sensor A Circuit Intermittent." This diagnostic trouble code (DTC) is triggered when the powertrain control module (PCM) detects an irregular signal from the knock sensor, which is crucial for monitoring and preventing engine knock or detonation.

Brake Pad Wear Indicators: Ensure Safety, Prevent Costly Repairs

Brake Pad Wear Indicators: Ensure Safety, Prevent Costly Repairs

Brake pad wear indicators are essential safety devices integrated into modern brake pads that alert drivers when the pads have worn down and require replacement. These indicators help maintain optimal braking performance, prevent damage to brake system components, and ultimately ensure the safety of the vehicle and its occupants.

In this article, we will explore the different types of brake pad wear indicators, how they work, and their benefits. We will also discuss when to replace brake pads with wear indicators, the importance of maintenance and inspection, and frequently asked questions about these critical safety devices.

I. Introduction

Brake system maintenance is crucial for ensuring the safety and reliability of any vehicle. Brake pads, which are responsible for generating the friction needed to slow down and stop the vehicle, wear down over time and require periodic replacement. Brake pad wear indicators play a vital role in alerting drivers when the pads have reached a critical level of wear and need to be replaced.

Brake pad wear indicators come in various types, each with its own unique features and benefits. Understanding how these indicators work and when to take action is essential for maintaining a safe and efficient braking system.

II. Types of Brake Pad Wear Indicators

A. Acoustic wear indicators

Acoustic wear indicators, also known as audible wear indicators, are small metal tabs or plates attached to the brake pad backing plate. As the brake pad wears down, the metal tab eventually contacts the brake rotor, producing a distinctive squealing or screeching noise. This noise serves as an audible warning to the driver, indicating that the brake pads need to be replaced soon.

One advantage of acoustic wear indicators is that they are relatively simple and inexpensive to manufacture. They also provide a clear and unmistakable warning to the driver when the brake pads have worn down to a critical level. However, some drivers may find the noise generated by these indicators to be annoying or mistakenly attribute it to other issues with the braking system.

B. Visual wear indicators

Visual wear indicators are small notches or grooves cut into the surface of the brake pad material. As the brake pad wears down, these notches become increasingly visible, providing a visual indication of the remaining pad thickness. Some visual wear indicators may also include a colored paint or coating that becomes exposed as the pad wears, making it easier for technicians to quickly assess the condition of the pads during routine maintenance.

The primary advantage of visual wear indicators is that they allow for a quick and easy visual inspection of the brake pads without the need for specialized tools or equipment. However, they do require the vehicle owner or technician to physically inspect the pads, which may not always be convenient or practical.

C. Electronic wear indicators

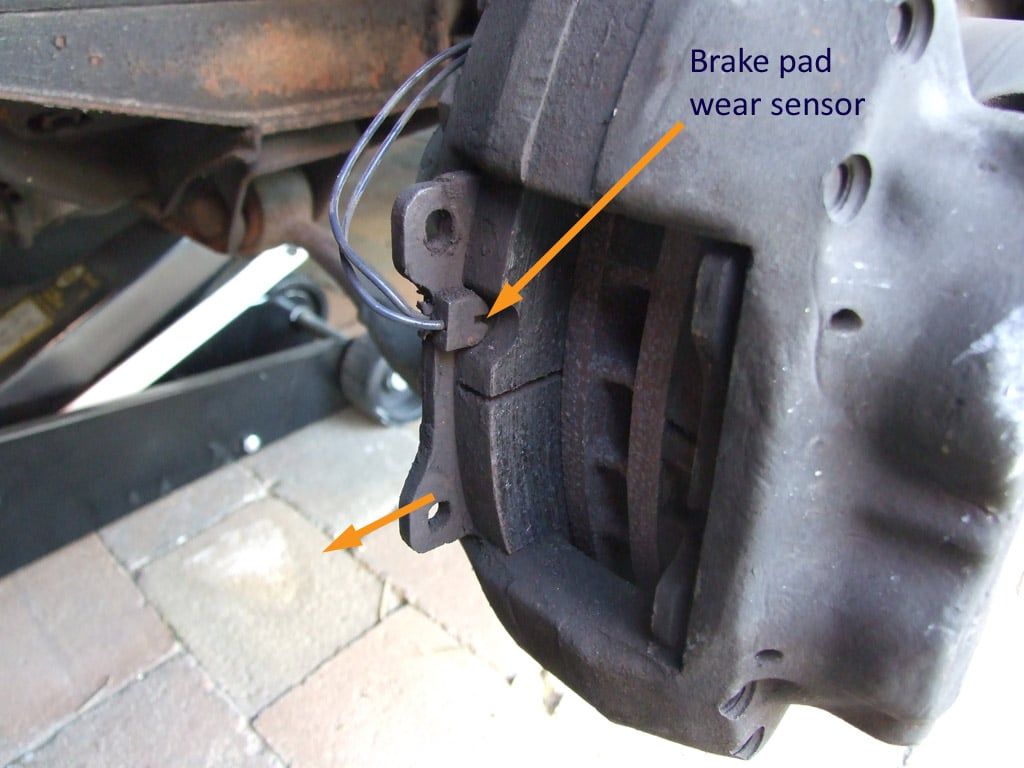

Electronic wear indicators use a small loop of wire with a low electrical current passing through it, embedded within the brake pad material. As the brake pad wears down, the wire loop becomes exposed and eventually contacts the brake rotor, creating an open circuit. This triggers a warning light on the vehicle's dashboard, alerting the driver that the brake pads need to be replaced.

The main benefit of electronic wear indicators is that they provide a clear and immediate warning to the driver through the vehicle's onboard diagnostic system. This allows for prompt action to be taken before the brake pads become dangerously worn. However, electronic wear indicators are more complex and expensive to manufacture compared to other types of indicators.

D. Two-stage sensors

Two-stage sensors are an advanced type of electronic wear indicator that utilizes two resistor circuits embedded at different depths within the brake pad material. As the brake pad wears down and the first circuit is breached, the system calculates the remaining brake pad life based on factors such as brake pressure, temperature, and mileage. This information is then displayed on the vehicle's dashboard as a numerical value or a color-changing warning light.

When the second circuit is breached, it indicates that the brake pads have reached a critical level of wear and require immediate replacement. Two-stage sensors provide a more accurate and informative assessment of brake pad wear compared to other types of indicators, allowing drivers to plan for maintenance and avoid unexpected breakdowns.

III. Benefits of Brake Pad Wear Indicators

A. Improved safety

Brake pad wear indicators play a crucial role in maintaining vehicle safety by alerting drivers when the brake pads have worn down to a critical level. By prompting timely brake pad replacement, these indicators help ensure that the braking system remains effective and reliable, reducing the risk of accidents caused by compromised braking performance.

B. Timely brake pad replacement

Wear indicators take the guesswork out of determining when brake pads need to be replaced. By providing clear visual, audible, or electronic warnings, these devices help drivers and technicians identify the need for brake pad replacement before it becomes a safety issue. This proactive approach to maintenance helps extend the life of the braking system and prevents more costly repairs down the line.

C. Prevention of costly repairs

Neglecting brake pad replacement can lead to damage to other components of the braking system, such as the brake rotors or calipers. Wear indicators help prevent this damage by alerting drivers to replace the pads before they wear down to the point of causing harm to other parts. By promoting timely brake pad replacement, wear indicators can save vehicle owners significant money on potential repairs.

D. Relationship between wear indicators and vehicle safety

The relationship between brake pad wear indicators and vehicle safety cannot be overstated. These devices serve as an essential early warning system, ensuring that drivers are aware of the condition of their brake pads and can take action before braking performance is compromised. By maintaining proper brake function, wear indicators contribute directly to the overall safety of the vehicle and its occupants.

IV. When to Replace Brake Pads with Wear Indicators

A. Mileage-based replacement

Many vehicle manufacturers provide recommendations for brake pad replacement based on mileage. These guidelines are designed to ensure that the brake pads are replaced before they become excessively worn, even if the wear indicators have not yet been activated. Following these mileage-based recommendations can help maintain optimal braking performance and prevent premature wear on other brake system components.

B. Wear indicator activation

When a brake pad wear indicator is activated, whether through an audible noise, visual cue, or electronic warning, it is a clear sign that the brake pads need to be replaced as soon as possible. Ignoring these warnings can lead to decreased braking performance and potential safety hazards. It is crucial to address wear indicator activations promptly to ensure the continued safe operation of the vehicle.

C. Signs of worn brake pads

In addition to wear indicator activations, there are other signs that can indicate the need for brake pad replacement. These include:

Reduced braking performance

Squealing or grinding noises during braking

Vibrations or pulsations in the brake pedal

Increased stopping distance

If any of these symptoms are observed, it is important to have the braking system inspected by a qualified technician to determine if the brake pads need to be replaced.

D. Importance of replacing wear indicators with brake pads

When replacing worn brake pads, it is essential to also replace the wear indicators. Wear indicators are designed to wear down along with the brake pads, ensuring that they provide accurate warnings throughout the life of the pads. Failing to replace the wear indicators can result in the warning system not functioning properly, potentially leading to unsafe braking conditions.

V. Maintenance and Inspection of Brake Pad Wear Indicators

A. Regular brake system inspections

To ensure the proper functioning of brake pad wear indicators and the overall health of the braking system, regular inspections should be performed by a qualified technician. During these inspections, the technician will assess the condition of the brake pads, rotors, calipers, and other components, as well as check the wear indicators for any signs of damage or malfunction.

B. Checking wear indicator functionality

In addition to regular inspections, it is important to periodically check the functionality of the brake pad wear indicators. This can be done by visually inspecting the indicators for any signs of damage or excessive wear, as well as listening for any unusual noises during braking. If an electronic wear indicator is present, the vehicle's onboard diagnostic system should be checked for any warning lights or error codes related to the braking system.

C. Correlation between brake pad material and wear rate

The type of material used in the construction of brake pads can have a significant impact on their wear rate and the effectiveness of the wear indicators. For example, ceramic brake pads typically have a slower wear rate compared to semi-metallic or organic pads, which can affect the lifespan of the wear indicators. It is important to consider the brake pad material when selecting replacement pads and wear indicators to ensure optimal performance and longevity.

| Brake Pad Material | Wear Rate | Brake Pad Lifespan | Braking Performance |

|---|---|---|---|

| Ceramic | Low | High | High |

| Semi-metallic | Medium | Medium | Medium |

| Organic | High | Low | Low |

This table compares the wear rate, lifespan, and braking performance of three common brake pad materials: ceramic, semi-metallic, and organic. Ceramic brake pads have the lowest wear rate, highest lifespan, and best braking performance. Semi-metallic pads have medium characteristics, while organic pads have the highest wear rate, lowest lifespan, and poorest braking performance.

D. Impact of brake rotor condition on wear indicator effectiveness

The condition of the brake rotors can also influence the effectiveness of brake pad wear indicators. If the rotors are excessively worn, warped, or damaged, they may cause uneven or premature wear on the brake pads, which can affect the accuracy of the wear indicators. To ensure proper functioning of the wear indicators and optimal braking performance, it is important to maintain the brake rotors in good condition and address any issues promptly.

| Brake Rotor Condition | Effect on Wear Indicators | Effect on Braking Performance |

|---|---|---|

| New | Accurate | Optimal |

| Resurfaced | Mostly accurate | Good |

| Worn | Less accurate | Reduced |

| Warped | Inaccurate | Poor |

| Damaged | Highly inaccurate | Severely compromised |

This table illustrates the impact of brake rotor condition on the effectiveness of wear indicators and overall braking performance. New brake rotors allow for accurate wear indicator readings and optimal braking performance. As the rotor condition deteriorates from resurfaced to worn, warped, and damaged, the accuracy of the wear indicators decreases, and braking performance suffers accordingly.

VI. Conclusion

Brake pad wear indicators are critical safety devices that help ensure the proper functioning and maintenance of a vehicle's braking system. By understanding the different types of wear indicators, their benefits, and when to take action, drivers can promote safer driving conditions and prevent costly repairs. As technology advances, it is likely that brake pad wear indicators will continue to evolve, providing even more accurate and informative warnings to help keep vehicles and their occupants safe on the road. Prioritizing brake system maintenance and paying attention to wear indicator warnings are essential steps in responsible vehicle ownership.

FAQs

What is the purpose of a brake pad wear indicator?

A brake pad wear indicator is a safety device designed to alert the driver when the brake pads have worn down to a critical level and need replacement. Its purpose is to maintain optimal braking performance, prevent damage to brake system components, and ensure vehicle safety.

Are brake pad wear indicators required on all vehicles?

While brake pad wear indicators are not legally required on all vehicles, they are a common feature on most modern cars and trucks. Some older vehicles may not have wear indicators, so it's important to visually inspect brake pads for wear.

Can brake pad wear indicators fail?

Yes, brake pad wear indicators can fail due to damage, corrosion, or improper installation. If a wear indicator fails, it may not alert the driver when brake pads are worn, so regular visual inspections are still important.

How do I know if my vehicle has brake pad wear indicators?

To determine if your vehicle has brake pad wear indicators, consult your owner's manual, look for wiring attached to the brake pads, or ask a mechanic during a brake service. Many vehicles have wear indicators, but some older models may not.

What should I do if my brake pad wear indicator activates?

If your brake pad wear indicator activates, either by making a squealing noise or illuminating a dashboard warning light, schedule a brake service appointment as soon as possible. Continuing to drive with worn brake pads can damage other brake components and compromise safety.

Can I replace just the brake pads without replacing the wear indicators?

No, when replacing worn brake pads, always install new wear indicators as well. Old wear indicators may be damaged or not match the thickness of the new brake pads, causing them to activate prematurely or not at all.

How long do brake pads typically last before the wear indicators activate?

Brake pad life varies widely depending on driving habits, vehicle type, and environmental conditions, but most pads last between 25,000 and 70,000 miles before wear indicators activate. However, it's best to visually inspect pads regularly and replace them when they reach minimum thickness, even if the wear indicators haven't activated yet.

Can I continue driving after my brake pad wear indicators have activated?

While you can continue driving for a short time after brake pad wear indicators have activated, it's best to replace the pads as soon as possible. Driving on worn pads can cause damage to brake rotors and compromise braking performance, so minimize driving until you can get the pads replaced.

Will my brake pad wear indicators make noise all the time once activated?

Brake pad wear indicators are designed to make noise intermittently when the brakes are applied, not constantly. If you hear continuous squealing or grinding noises from your brakes, even when not braking, it may indicate a more serious problem, and you should have your brakes inspected immediately.

Can brake pad wear indicators be adjusted or disabled?

No, brake pad wear indicators are not adjustable and should not be disabled. They are an important safety feature designed to activate at a specific brake pad thickness. If your wear indicators are activating prematurely or not at all, have your brakes inspected by a professional mechanic to diagnose and correct the problem.

Bình luận (0)

Bài viết đề xuất

The P0032 diagnostic trouble code indicates an issue with the heater control circuit for the heated oxygen sensor on Bank 1, Sensor 1. This sensor plays a vital role in monitoring the air-fuel mixture and ensuring optimal combustion and emissions control. When the powertrain control module (PCM) detects an abnormally high voltage in this circuit, it triggers the P0032 code.

The alternator is a vital component that charges the battery and powers the electrical system while the engine runs. Knowing the correct alternator amperage for your vehicle is crucial for proper maintenance, repairs, and supporting electrical demands. This article will guide you through various methods to determine your vehicle's original alternator amperage using the Vehicle Identification Number (VIN).

As an experienced automotive mechanic, I've encountered countless cases where car owners neglected the importance of maintaining proper coolant levels, leading to costly repairs and frustrating breakdowns.

Bài viết liên quan

Adopting safe and efficient driving habits is crucial for every driver on the road. Two key areas to focus on are avoiding aggressive braking and reducing towing loads. By mastering these techniques, you can enhance your vehicle's performance, improve fuel economy, and prioritize the safety of yourself and others.