A car's heating system is designed to provide warmth and comfort to the cabin during cold weather conditions. However, it's not uncommon for drivers to experience issues where the heater blows cold air while the vehicle is idling.

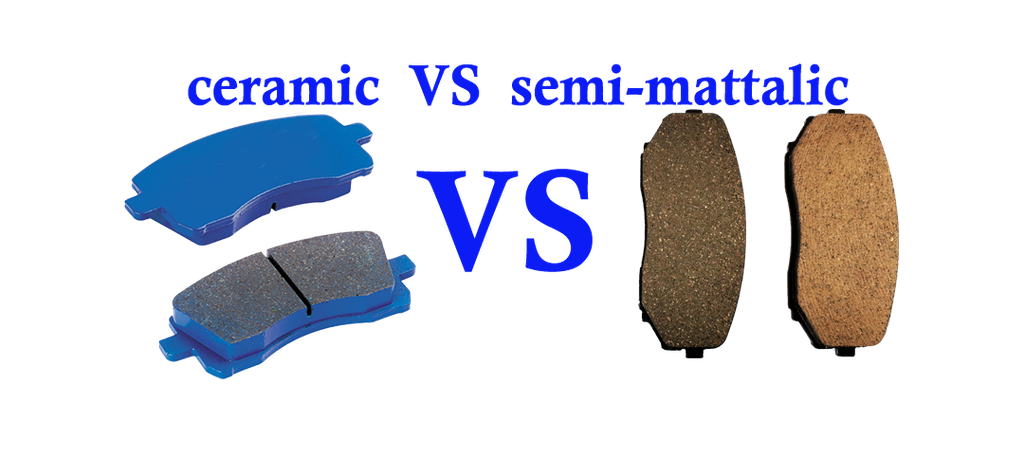

Ceramic vs. Semi-Metallic Brake Pads: The Ultimate Comparison

Ceramic vs. Semi-Metallic Brake Pads: The Ultimate Comparison

Brake pads are essential components that enable a vehicle to decelerate and stop safely. They are designed to withstand extreme temperatures and provide consistent braking performance throughout their lifespan. In this comprehensive article, we will delve into the two most popular types of brake pads: ceramic and semi-metallic, exploring their compositions, advantages, disadvantages, and suitability for various driving conditions.

Introduction

Brake pads play a crucial role in ensuring the safety and performance of a vehicle's braking system. As the primary components responsible for creating friction against the brake rotors, they convert the kinetic energy of a moving vehicle into thermal energy, effectively slowing it down or bringing it to a complete stop.

Understanding the differences between ceramic and semi-metallic brake pads is crucial for selecting the most suitable option for your driving needs. Let's begin by exploring the importance of brake pads and the different types available.

| Importance of Brake Pads | Types of Brake Pads |

|---|---|

| - Ensure vehicle safety | - Ceramic |

| - Enable controlled deceleration | - Semi-metallic |

| - Convert kinetic energy to thermal energy | - Organic |

| - Provide consistent braking performance | - Non-asbestos organic (NAO) |

Ceramic Brake Pads

Ceramic brake pads are made from a dense ceramic compound, often reinforced with fine copper fibers or other metallic fibers to enhance friction and heat conductivity. These pads offer several advantages and are a popular choice for many drivers.

Composition and Materials

Dense ceramic compound

Reinforced with fine copper fibers or other metallic fibers

Enhances friction and heat conductivity

Advantages

Quiet Operation

One of the most notable advantages of ceramic brake pads is their quiet braking performance. They emit noise frequencies outside the range of human hearing, resulting in a quieter and more comfortable driving experience.

Reduced Brake Dust

Ceramic pads produce significantly less brake dust compared to other types, such as semi-metallic or organic pads. This results in cleaner wheels and reduced maintenance requirements, as brake dust accumulation is minimized.

| Brake Dust Comparison |

|---|

| Ceramic: Low brake dust production |

| Semi-metallic: High brake dust production |

| Organic: Moderate brake dust production |

Longer Lifespan

Due to their durable composition, ceramic brake pads tend to have a longer lifespan than organic or semi-metallic alternatives. This can translate into cost savings over time, as they require less frequent replacements.

Consistent Performance

Ceramic pads maintain stable braking performance across a wide range of temperatures, making them suitable for various driving conditions. They provide reliable and consistent braking power, regardless of the ambient temperature.

Durability

The ceramic material used in these brake pads is resistant to corrosion, salt, and water. This makes them a good choice for harsher climates or environments with salted roads, as they are less susceptible to premature wear and degradation.

Disadvantages

Higher Cost

One of the drawbacks of ceramic brake pads is their higher cost compared to other brake pad options. This is due to the advanced materials and manufacturing processes involved in their production.

Reduced Cold Bite

Ceramic pads may not provide optimal braking performance when cold, requiring some warm-up time to reach their full potential. This can be a consideration for drivers in colder climates or those who frequently make short trips.

Potential for Increased System Temperatures

Due to their insulating properties, ceramic pads may transfer more heat into the braking system, potentially causing increased wear on other components such as rotors and calipers.

Not Recommended for Severe-Duty Applications

While ceramic pads are suitable for daily driving and moderate conditions, they are not ideal for severe-duty applications like hauling, towing, or racing. In these situations, they may require greater pressure on the system to achieve the same stopping power as under regular driving conditions.

Semi-Metallic Brake Pads

Semi-metallic brake pads, also known as metallic brake pads, contain a high percentage of metals such as iron, copper, steel wool, or other composite alloys, typically ranging from 30% to 70% of the pad's composition. These pads are known for their superior stopping power and heat dissipation capabilities.

Composition and Materials

High percentage of metals (30% to 70%)

Iron

Copper

Steel wool

Composite alloys

Advantages

Superior Stopping Power

One of the primary advantages of semi-metallic pads is their superior stopping power. They provide excellent braking performance, making them suitable for high-performance vehicles or situations requiring sudden stops.

Excellent Heat Dissipation

The metallic components in semi-metallic pads allow for effective heat transfer during braking, helping to prevent overheating and reducing the risk of brake fade. This is particularly beneficial in demanding driving conditions or when frequent braking is required.

Good Cold Bite

Unlike some other brake pad types, semi-metallic pads perform well even in cold weather conditions, providing reliable braking performance without the need for an extended warm-up period.

Fade Resistance

Semi-metallic brake pads are highly resistant to brake fade, a phenomenon where braking performance decreases due to excessive heat buildup. This makes them a suitable choice for drivers who frequently encounter situations that require repeated or prolonged braking.

Disadvantages

Increased Noise and Vibration

The metal-to-rotor contact in semi-metallic pads can generate more noise and vibration during braking compared to ceramic pads. This can be a concern for drivers who prioritize a quieter driving experience.

| Noise and Vibration Comparison |

|---|

| Ceramic: Quiet operation |

| Semi-metallic: Increased noise and vibration |

Higher Brake Dust Production

Semi-metallic pads tend to produce more brake dust than ceramic alternatives. This brake dust can accumulate on wheels and require more frequent cleaning to maintain a clean appearance.

Faster Rotor Wear

Due to their harder composition, semi-metallic pads may cause accelerated wear on brake rotors. This can potentially lead to more frequent rotor replacements, increasing maintenance costs over time.

Comparison of Ceramic vs. Semi-Metallic Brake Pads

When comparing ceramic and semi-metallic brake pads, several key factors should be considered to determine the most suitable option for your driving needs.

| Factor | Ceramic | Semi-Metallic |

|---|---|---|

| Noise Levels | Significantly quieter | Increased noise and vibration |

| Brake Dust | Low brake dust production | High brake dust production |

| Lifespan | Longer lifespan | Shorter lifespan |

| Performance | Good braking performance | Superior stopping power and cold bite |

| Heat Dissipation | Moderate heat dissipation | Excellent heat dissipation |

| Cost | Higher upfront cost | Lower upfront cost |

Noise Levels

Ceramic brake pads are significantly quieter than semi-metallic pads, making them a preferred choice for drivers who value a quieter driving experience and want to minimize noise and vibration during braking.

Brake Dust

Ceramic pads produce less brake dust compared to semi-metallic alternatives, resulting in cleaner wheels and reduced maintenance requirements. If minimizing brake dust accumulation is a priority, ceramic pads may be the better choice.

Lifespan

Ceramic brake pads generally have a longer lifespan compared to semi-metallic pads, potentially reducing replacement costs over time. However, the lifespan can vary depending on driving conditions and maintenance practices.

Performance

Semi-metallic pads offer superior stopping power and better cold bite, making them more suitable for high-performance driving or extreme conditions where sudden stops or frequent braking is required.

Heat Dissipation

Semi-metallic pads excel at dissipating heat, reducing the risk of brake fade and overheating in demanding situations, such as towing, hauling, or track driving.

Cost

While ceramic brake pads are typically more expensive upfront, their longer lifespan can offset the higher initial cost over time. Semi-metallic pads may be more cost-effective for drivers who prioritize performance over longevity.

Choosing the Right Brake Pads

Selecting the appropriate brake pads for your vehicle is crucial to ensure optimal braking performance, safety, and driving experience. Consider the following factors when making your choice:

Driving Style

Spirited or high-performance driving

Semi-metallic pads for superior stopping power and fade resistance

Daily commuting or city driving

Ceramic pads for quieter and cleaner experience

Vehicle Type

High-performance vehicles, trucks, or vehicles used for towing

Semi-metallic pads for better performance

Luxury or passenger vehicles

Ceramic pads for quieter operation and reduced brake dust

Climate and Driving Conditions

Cold weather or extreme conditions

Semi-metallic pads for better cold bite and performance

Moderate climates

Ceramic pads for consistent performance

Personal Preferences

Prioritize quieter driving experience and reduced brake dust

Ceramic pads

Prioritize performance and fade resistance

Semi-metallic pads

Installation and Maintenance

Proper installation and maintenance are crucial for both ceramic and semi-metallic brake pads to ensure optimal performance and longevity.

Proper Installation and Bedding-in Procedures

Follow manufacturer's instructions carefully

Proper bedding-in procedures

Ensure brake pads and rotors mate correctly

Maximize lifespan and performance

Regular Maintenance and Inspections

Inspect brake pad thickness and rotor condition regularly

Semi-metallic pads may require more frequent rotor replacements due to increased wear

Conclusion

Choosing between ceramic and semi-metallic brake pads ultimately depends on your driving style, vehicle type, climate conditions, and personal preferences. Ceramic brake pads excel in quietness, reduced brake dust, and consistent performance across various temperatures, making them an excellent choice for daily commuting and luxury vehicles. On the other hand, semi-metallic brake pads provide superior stopping power, excellent heat dissipation, and fade resistance, making them ideal for high-performance driving, extreme conditions, or heavy-duty applications.

By considering the factors discussed in this article, you can make an informed decision and select the most suitable brake pads for your specific needs, ensuring optimal braking performance, safety, and driving experience.

FAQs

What are the main differences between ceramic and semi-metallic brake pads?

The key differences are that ceramic pads produce less brake dust, are quieter, and last longer but are more expensive. Semi-metallic pads offer better braking performance, especially in cold weather, but make more noise and dust.

Which type of brake pad is better for high-performance driving?

Semi-metallic brake pads are better suited for high-performance driving, racing, towing, or situations requiring sudden stops due to their superior stopping power and fade resistance.

Do ceramic brake pads require a break-in period?

Yes, ceramic brake pads typically require a break-in procedure of making several slow stops to allow the pads to mate properly with the rotors for optimal performance.

How does cold weather affect ceramic vs semi-metallic brake pads?

Ceramic pads can have reduced braking performance in extremely cold temperatures until they warm up, while semi-metallic pads maintain better cold bite and braking in cold conditions.

Which type of brake pad causes more wear on brake rotors?

Semi-metallic brake pads are more abrasive and cause accelerated wear on brake rotors compared to ceramic pads which are gentler on rotors.

Are ceramic brake pads suitable for all vehicle types?

No, ceramic brake pads may not be compatible with all vehicle makes and models, so checking compatibility is advised before installing them.

How does brake dust production compare for each pad type?

Ceramic brake pads produce very low levels of light brake dust, while semi-metallic pads generate significantly more brake dust that requires more frequent cleaning.

Can ceramic brake pads be used for towing or hauling heavy loads?

Ceramic brake pads are generally not recommended for severe duty applications like towing or hauling heavy loads where the increased stopping power of semi-metallic pads is better suited.

Do ceramic or semi-metallic brake pads make more noise?

Semi-metallic brake pads are known to produce more noise like squealing or grinding compared to ceramic pads which operate very quietly.

Which brake pad type has a higher upfront cost?

Ceramic brake pads typically have a higher upfront cost compared to semi-metallic brake pads due to the advanced materials and manufacturing processes involved.

Bình luận (0)

Bài viết đề xuất

The P032A code refers to a malfunction in the Knock/Combustion Vibration Sensor C Circuit, specifically in Bank 1. This sensor detects engine knocking or pinging, which can occur when the air/fuel mixture in the combustion chamber ignites prematurely. The sensor sends signals to the engine control module (ECM) to adjust the ignition timing and prevent engine damage.

Oil pressure is a critical aspect of an engine's lubrication system. It refers to the force that pushes the engine oil through the various components, ensuring proper lubrication and preventing excessive wear and tear

The air conditioning (AC) system in modern cars is designed to maintain a comfortable cabin temperature and humidity level. However, some car owners may experience their AC turning on automatically, even when they haven't manually activated it.