A humming noise coming from the transmission while accelerating is a common issue that many car owners face. This noise can be an indication of various underlying problems within the transmission system, ranging from minor issues to more severe ones that require immediate attention.

Clogged Transmission Line Symptoms: Signs of a Blocked Filter & What to Do

Clogged Transmission Line Symptoms: Signs of a Blocked Filter & What to Do

Introduction

A transmission line is a critical component of a vehicle's transmission system, responsible for transferring power from the engine to the wheels. It consists of various components, including the transmission fluid, filters, coolers, and lines. A clogged transmission line can lead to several issues, affecting the overall performance and efficiency of the transmission system. Understanding the symptoms of a clogged transmission line is crucial for timely detection and proper maintenance.

Understanding the Transmission Line

Before we dive into the symptoms and solutions, let's first understand the role of the transmission line. This vital component is responsible for carrying transmission fluid throughout the system, ensuring smooth gear shifts and proper lubrication of the internal components.

| Function | Description |

|---|---|

| Fluid Delivery | The transmission line carries transmission fluid to various parts of the system, ensuring proper lubrication and cooling. |

| Gear Shifting | Smooth and efficient gear shifts rely on the uninterrupted flow of transmission fluid through the line. |

| Component Protection | The fluid helps protect internal transmission components from excessive wear and tear. |

When this line becomes clogged, it can disrupt the flow of fluid, leading to a cascade of issues that can ultimately result in transmission failure if not addressed promptly.

Common Causes of a Clogged Transmission Line

Over the years, I've encountered various reasons why transmission lines become clogged. Here are some of the most prevalent causes:

Lack of Regular Maintenance: Failing to change the transmission fluid and filter as recommended by the manufacturer can lead to sludge buildup and contamination within the line.

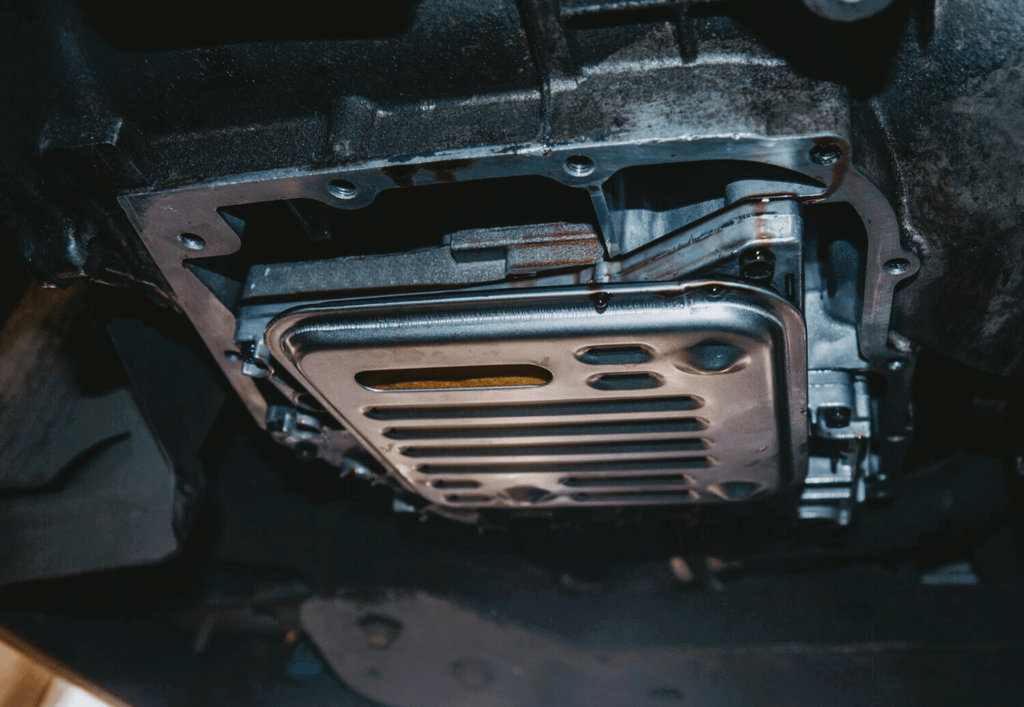

Damaged or Faulty Transmission Filter: This crucial component is designed to remove contaminants from the fluid, but if it's not functioning properly, debris can circulate and eventually clog the lines.

Internal Transmission Problems: Issues such as worn-out parts or bearing failure can introduce metal shavings and other debris into the fluid, leading to clogged lines.

Coolant Contamination: If the transmission cooler lines become damaged or corroded, coolant can mix with the transmission fluid, causing sludge formation and blockages.

| Cause | Description |

|---|---|

| Lack of Maintenance | Neglecting regular fluid and filter changes can lead to sludge buildup. |

| Faulty Transmission Filter | A damaged filter cannot effectively remove contaminants from the fluid. |

| Internal Transmission Issues | Worn-out parts or bearing failure can introduce debris into the fluid. |

| Coolant Contamination | Coolant mixing with transmission fluid can cause sludge formation. |

Identifying the Symptoms

As a mechanic, I've learned to recognize the telltale signs of a clogged transmission line. Here are some of the most common symptoms:

Transmission Fluid Leaks: If you notice puddles of reddish fluid under your vehicle, it's a clear sign that something is amiss.

Overheating Transmission: When the fluid flow is restricted, the transmission components can't be properly lubricated and cooled, leading to excessive heat buildup.

Slipping or Delayed Gear Shifts: Hesitation or harsh shifts can indicate that the transmission line is clogged, preventing the fluid from flowing smoothly.

Grinding or Whining Noises During Shifts: These sounds often indicate that the transmission components are not receiving adequate lubrication due to a clogged line.

Burning Smell from the Transmission: If you notice a burning smell emanating from the transmission area, it's a clear indication that something is seriously wrong, and you should have your vehicle inspected immediately.

| Symptom | Description |

|---|---|

| Fluid Leaks | Puddles of reddish fluid under the vehicle. |

| Overheating | Restricted fluid flow leads to excessive heat buildup. |

| Slipping/Delayed Shifts | Hesitation or harsh shifts due to fluid flow restriction. |

| Grinding/Whining Noises | Lack of proper lubrication due to clogged line. |

| Burning Smell | A burning smell from the transmission area indicates a serious issue. |

Diagnosing the Issue

When a customer brings in their vehicle with suspected transmission line issues, I follow a systematic approach to diagnose the problem:

Check Transmission Fluid Level and Condition: Low fluid levels or discolored, contaminated fluid can be an early indicator of a clogged line.

Visual Inspection of Transmission Lines: I carefully inspect the transmission lines for any signs of damage, such as cracks, bulges, or leaks. These can be potential entry points for contaminants or areas where blockages may occur.

Engine Noise and Vibration Analysis: I start the engine and listen carefully for any unusual noises or vibrations coming from the transmission area, which could signify a clogged line or other internal issues.

Observe Shifting Behavior: During a test drive, I observe the shifting behavior. Delayed or harsh shifts can be a clear symptom of a clogged line or other transmission problems.

Repairing a Clogged Transmission Line

Once I've identified the clogged transmission line as the culprit, it's time to take action. The repair process typically involves one of two approaches: replacement or cleaning.

Replacement Procedure

If the line is severely clogged or damaged, replacement is often the best course of action. Here's the typical procedure:

Safely raise and support the vehicle.

Locate and disconnect the affected transmission line(s).

Remove the old line(s) and inspect for any debris or blockages.

Install the new line(s), ensuring proper routing and connections.

Refill the transmission with fresh fluid and bleed the system if necessary.

Test drive the vehicle and check for proper operation.

Cleaning Procedure

In some cases, the transmission line may not need to be replaced, and a thorough cleaning can resolve the issue. Here's how I approach the cleaning process:

Disconnect the affected line(s) from the transmission and cooler.

Use compressed air or a specialized transmission line cleaning tool to dislodge any debris or blockages.

Flush the line(s) with clean transmission fluid or a solvent cleaner.

Reconnect the line(s) and refill the transmission with fresh fluid.

Throughout the repair process, I always emphasize the importance of using the correct transmission fluid type and quantity specified by the manufacturer. Additionally, I replace any damaged or corroded lines to prevent future issues and ensure proper torque specifications when tightening line fittings. Bleeding the system properly is also crucial to remove any air pockets that could cause further problems.

| Repair Method | Steps |

|---|---|

| Replacement | 1. Raise and support the vehicle 2. Disconnect affected line(s) 3. Remove old line(s) and inspect 4. Install new line(s) 5. Refill fluid and bleed system 6. Test drive and check operation |

| Cleaning | 1. Disconnect affected line(s) 2. Use compressed air or cleaning tool 3. Flush line(s) with fluid or solvent 4. Reconnect line(s) and refill fluid |

Preventing Recurrence

While repairing a clogged transmission line is essential, preventing the issue from recurring is equally important. As a mechanic, I always stress the importance of regular maintenance to my customers.

Follow Manufacturer's Service Intervals: Adhering to the recommended service intervals for transmission fluid and filter changes is crucial. Neglecting these routine maintenance tasks can lead to sludge buildup and contamination, increasing the risk of clogged lines.

Inspect Transmission Lines During Maintenance: I advise my customers to inspect the transmission lines during routine maintenance for any signs of damage or leaks. Addressing these issues early can prevent more significant problems down the line.

Avoid Excessive Load and High-Stress Driving: Excessive load or high-stress driving conditions can accelerate transmission wear, increasing the risk of clogged lines.

Warm Up the Transmission: Warming up the transmission before engaging in high-load activities can help prevent excessive strain and potential damage.

Address Transmission Issues Promptly: Promptly addressing any transmission-related issues can help prevent further damage and clogged lines.

| Prevention Measure | Description |

|---|---|

| Regular Maintenance | Follow recommended fluid and filter change intervals. |

| Line Inspection | Inspect transmission lines during routine maintenance. |

| Proper Usage | Avoid excessive load and high-stress driving conditions. |

| Warm-Up | Warm up the transmission before high-load activities. |

| Prompt Attention | Address transmission issues promptly to prevent further damage. |

Cost Considerations

When it comes to repairing a clogged transmission line, cost is often a concern for vehicle owners. As a mechanic, I understand the importance of transparency and providing accurate estimates.

Labor Costs: Expect to pay between $100 and $300 for labor, depending on the complexity of the repair and the hourly rate of the mechanic or dealership.

Parts Costs: Replacement transmission lines typically range from $50 to $200, depending on the vehicle make and model.

Additional Repairs: If the clogged line has caused further damage to the transmission or other components, additional repair costs may be incurred.

| Cost Factor | Typical Range |

|---|---|

| Labor | $100 - $300 |

| Replacement Lines | $50 - $200 |

| Additional Repairs | Varies based on extent of damage |

While the upfront cost of repairing a clogged transmission line may seem daunting, it's essential to address the issue promptly. Neglecting the problem can lead to more extensive and costly repairs in the future, or even complete transmission failure, which can be a financial nightmare.

Conclusion

As an automotive mechanic, I've witnessed firsthand the havoc that a clogged transmission line can wreak on a vehicle. From slipping gears and overheating transmissions to costly repairs, this seemingly minor issue can quickly escalate into a major problem if left unaddressed.

By understanding the symptoms, causes, and repair procedures, vehicle owners can take proactive steps to maintain their transmission's health and prevent costly breakdowns. Regular maintenance, proper usage, and prompt attention to any transmission-related issues are key to avoiding clogged lines and ensuring a smooth, reliable driving experience.

Remember, a little preventative care can go a long way in extending the lifespan of your vehicle's transmission and saving you from the headaches and expenses associated with major repairs. So, the next time you notice any unusual behavior or warning signs, don't hesitate to bring your vehicle in for a professional inspection. Your trusted mechanic will be there to diagnose and resolve the issue, keeping your ride running smoothly for years to come.

FAQs

What is the process for decommissioning a transmission line?

The process involves the Alberta Electric System Operator determining the need for decommissioning, directing ATCO Electric to prepare a facilities application, and obtaining approval from the Alberta Utilities Commission.

What happens to the transmission line infrastructure after decommissioning?

If the line is not converted to another use, all infrastructure will be removed, with parts being reused, recycled, or disposed of properly. The right-of-way will be restored to the surrounding land use.

Can a decommissioned transmission line be converted to a distribution line?

Yes, a decommissioned transmission line can be converted to use as a distribution line, in which case the conductor wire and structures remain in place but carry a lower voltage.

Are landholders consulted during the decommissioning process?

Yes, ATCO Electric contacts landholders in the vicinity of the decommissioning project to discuss the schedule and activities to be performed on private property.

How are pole locations filled after removal?

Pole locations are filled with gravel or sand up to the topsoil layer, then capped with clean topsoil and restored to the surrounding land use.

What happens to the conductor wire after decommissioning?

The conductor wires are recycled for their metal content, as they are unsuitable for reuse in new transmission or distribution lines.

Are there any potential damages to land or crops during decommissioning?

While unlikely, ATCO Electric is responsible for any damages that may occur to crops or private property as a direct result of their work during decommissioning or reclamation.

How does ATCO Electric protect against soil-borne diseases during reclamation?

ATCO Electric follows best management practices to prevent the spread of soil-borne diseases, such as cleaning equipment before moving to a new location.

Can landholders use the reclaimed right-of-way for other purposes?

Generally, any agreements ATCO Electric had with the landholder regarding the use of the land for the right-of-way will end when it is no longer used for transmission line facilities.

What happens to the materials removed during decommissioning?

ATCO Electric recycles and reuses poles and transmission line materials whenever possible. Any materials that cannot be reused are disposed of using ATCO Electric's waste minimization and disposal practices.

Bình luận (0)

Bài viết đề xuất

White smoke from the exhaust on startup is a common issue that many vehicle owners encounter. This phenomenon occurs when unburned fuel condenses in the exhaust system, creating a white vapor that is visible upon starting the engine.

A muffler is an essential component of a vehicle's exhaust system, responsible for reducing the noise and emissions produced by the engine. Over time, mufflers can become damaged or worn out, requiring repair or replacement. One option for fixing a damaged muffler is to have it

Dead car batteries can be a frustrating experience, leaving you stranded and in need of a costly replacement. However, before you invest in a new battery, consider these four proven methods to revive and recondition dead cells, potentially extending the lifespan of your existing battery.

Bài viết liên quan

Failing to shift out of first gear is a common issue that can occur in both manual and automatic transmission vehicles. This problem can be caused by various factors, ranging from simple maintenance issues to more complex mechanical failures.

Just the other day, I had a customer bring in their car with a rather peculiar issue. As they were driving down the highway, a warning message flashed on the dash - "Transmission Not in Park." Naturally, they were quite alarmed since the car was very much in motion and not parked at all. This is the kind of situation that gets a mechanic's brain working to diagnose the root cause.

The "Shift to Park" message is a common issue that many drivers experience with their vehicles, particularly those manufactured by General Motors (GM). This error message appears on the instrument cluster or driver information center, even when the vehicle is already in the park position.

The transmission is a vital component of a vehicle's drivetrain, responsible for transferring power from the engine to the wheels. It plays a crucial role in ensuring smooth gear shifts and efficient power delivery.

Transmission fluid is a vital component in both automatic and manual transmissions, responsible for lubricating and cooling the internal components, enabling smooth gear shifts, and preventing excessive wear and tear.

Transmission fluid is a vital component in the proper functioning of a vehicle's transmission system. It serves as a lubricant, hydraulic fluid, and coolant, ensuring smooth gear shifts and protecting the transmission components from excessive wear and heat.