Oil pressure is a critical factor in ensuring the proper lubrication and functioning of an engine. It refers to the force that drives the engine oil through the various components, providing a thin film of lubrication between moving parts.

Coolant Temperature Regulation: Keeping Your Engine Running Optimally

Coolant Temperature Regulation: Keeping Your Engine Running Optimally

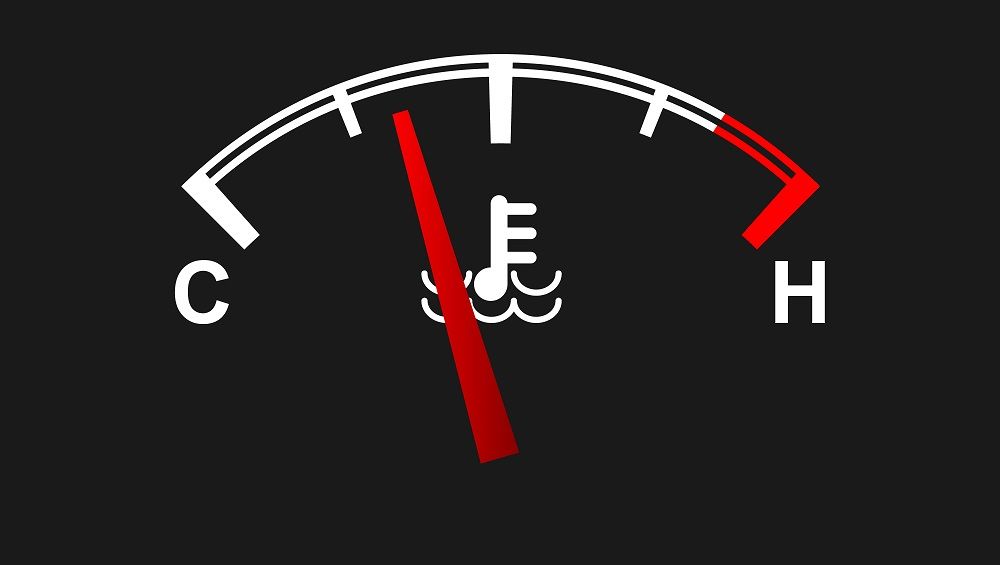

The coolant temperature regulation system plays a crucial role in maintaining optimal engine performance and longevity. This intricate process ensures that the engine operates within a specific temperature range, preventing overheating and potential damage. In this comprehensive article, we will explore the key components and mechanisms involved in coolant temperature regulation, their functions, and the importance of proper maintenance.

The engine cooling system comprises several vital components that work together to regulate the engine's temperature effectively. These components include the thermostat, radiator, water pump, coolant mixture, overflow tank, and temperature sensors. Each component plays a specific role in the overall cooling process, ensuring efficient heat transfer and proper coolant circulation.

I. Introduction to Engine Cooling

A. Importance of Proper Temperature Regulation

Effective temperature regulation is crucial to dissipate the significant amount of heat generated by the internal combustion engine during operation. Overheating can lead to various issues, including:

Decreased efficiency

Increased emissions

Potential catastrophic engine failure

Maintaining the engine within its optimal operating temperature range is essential for optimal performance and longevity.

B. Overview of the Cooling System Components

The cooling system comprises the following key components:

Thermostat

Radiator

Water pump

Coolant mixture

Overflow tank

Temperature sensors

These components work in harmony to regulate the engine's temperature through efficient heat transfer and coolant circulation.

II. The Thermostat: The Heart of Temperature Control

A. How the Thermostat Operates

The thermostat is a valve that controls the flow of coolant between the engine and radiator, playing a crucial role in temperature regulation. Its operation can be broken down into three stages:

a. Closed at Startup

When the engine is first started from cold, the thermostat remains closed, preventing coolant from flowing through the radiator. This allows the engine to warm up quickly by circulating the coolant solely within the engine block and cylinder head.

b. Opening Point

As the engine warms up, the thermostat begins to open at a predetermined temperature, typically around 195°F (90°C). This allows a portion of the hot coolant to flow through the radiator, where it can release its heat.

c. Modulating Coolant Flow

The thermostat modulates the amount it opens based on the coolant temperature. The hotter the coolant, the more the thermostat opens to allow increased flow through the radiator for greater cooling. Conversely, as the coolant cools, the thermostat closes more to reduce coolant flow through the radiator.

B. Thermostat Failure Symptoms and Replacement

A failing thermostat can cause significant issues in the cooling system. The table below outlines the symptoms and consequences of a stuck-closed and stuck-open thermostat:

| Thermostat Condition | Symptoms | Consequences |

|---|---|---|

| Stuck-closed | Overheating, fluctuating temperature readings, poor engine performance | Engine damage due to overheating |

| Stuck-open | Engine takes longer to reach operating temperature, decreased efficiency | Increased emissions, poor fuel economy |

Regular maintenance and timely replacement of the thermostat are essential to ensure proper cooling system operation and prevent potential engine damage.

III. The Radiator: Dissipating Engine Heat

A. Radiator Core and Fin Design

The radiator is a heat exchanger designed to transfer heat from the hot coolant to the surrounding air. Its core consists of a series of thin metal tubes and fins, providing a large surface area for efficient heat transfer. The table below compares the characteristics of different radiator core designs:

| Core Design | Fin Density | Heat Transfer Efficiency | Airflow Resistance |

|---|---|---|---|

| Tube and Fin | High | Excellent | Moderate |

| Parallel Flow | Moderate | Good | Low |

| Crossflow | Low | Fair | High |

The fin density and core size are optimized to maximize heat dissipation while minimizing airflow resistance, ensuring efficient cooling and minimal drag.

B. Airflow Through the Radiator

Adequate airflow through the radiator core is essential for effective heat dissipation. This airflow is achieved through two primary mechanisms:

a. Radiator Fan Operation

At low speeds or when idling, the radiator fan assists in drawing air through the radiator core. The fan is typically controlled by the engine computer based on coolant temperature readings, ensuring adequate airflow for cooling.

b. Driving Speed and Ram Air Effect

At higher speeds, the vehicle's forward motion creates a ram air effect, forcing air through the radiator core without the need for the fan. This natural airflow helps to dissipate heat more effectively during highway driving.

C. Radiator Maintenance and Issues

Proper radiator maintenance is crucial to ensure efficient cooling. This includes:

Regular inspections for leaks

Checking for debris buildup

Examining for fin damage

A clogged or damaged radiator can significantly reduce its cooling capacity, leading to overheating issues and potential engine damage.

IV. Coolant Circulation and the Water Pump

A. Impeller and Pump Operation

The water pump is responsible for circulating the coolant throughout the cooling system. It consists of an impeller that draws coolant from the radiator and forces it through the engine block and cylinder head.

B. Coolant Flow Paths in the Engine

a. Engine Block Water Jackets

The engine block contains water jackets, which are channels surrounding the cylinders. As the coolant flows through these jackets, it absorbs heat from the combustion process, effectively cooling the engine.

b. Cylinder Head Coolant Passages

Similarly, the cylinder head has coolant passages that allow the hot coolant to flow around the combustion chambers and valves, dissipating heat from these critical components.

C. Water Pump Failure Signs

A failing water pump can lead to overheating and potential engine damage. Signs of a failing water pump include:

Coolant leaks

Abnormal noises

Overheating issues, even with a properly functioning thermostat and radiator

Addressing water pump issues promptly is crucial to prevent further damage to the cooling system and engine.

V. Coolant Composition and the Overflow System

A. Water and Antifreeze Mixture

a. Freeze and Boil Protection

The coolant mixture typically consists of water and antifreeze (ethylene glycol or propylene glycol). This mixture serves two primary purposes:

Preventing freezing in cold temperatures

Raising the boiling point to prevent overheating

The table below shows the typical freeze and boil protection provided by different coolant mixture ratios:

| Coolant Mixture Ratio (Antifreeze:Water) | Freeze Protection | Boil Protection |

|---|---|---|

| 50:50 | -34°F (-37°C) | 265°F (129°C) |

| 60:40 | -62°F (-52°C) | 270°F (132°C) |

| 70:30 | -84°F (-64°C) | 276°F (136°C) |

b. Corrosion Inhibitors

Additionally, the coolant mixture contains corrosion inhibitors that help protect the cooling system components from rust and scale buildup, extending their lifespan.

B. Coolant Reservoir and Overflow Tank

a. Allowing for Expansion

As the coolant heats up, it expands in volume. The overflow tank provides a reservoir for this excess coolant, preventing it from being forced out of the system.

b. Recovering Coolant Loss

Over time, some coolant may be lost through normal operation or minor leaks. The overflow tank allows for the recovery of this lost coolant, ensuring that the system remains properly filled.

VI. Temperature Monitoring and Regulation

A. Coolant Temperature Sensors

Coolant temperature sensors, typically located near the thermostat housing or cylinder head, monitor the coolant temperature and relay this information to the engine computer.

B. Engine Computer and Cooling Fan Control

The engine computer uses the temperature data to regulate the cooling system components, such as the radiator fan and, in some cases, the water pump speed. This ensures that the cooling system operates efficiently under various driving conditions and engine loads.

C. Driving Conditions and Cooling Needs

Different driving conditions can affect the engine's cooling needs. The table below outlines the cooling requirements for various driving scenarios:

| Driving Condition | Cooling Needs |

|---|---|

| Stop-and-go traffic | Increased cooling due to frequent idling and low airflow |

| Highway cruising | Moderate cooling due to ram air effect |

| Towing or hauling | Increased cooling due to higher engine loads |

The computer adjusts the cooling system components accordingly to maintain the optimal temperature range for each driving condition.

VII. Cooling System Maintenance

A. Coolant Flush Intervals

Regular coolant flushes are recommended to remove any accumulated contaminants and replenish the coolant mixture. The recommended interval varies based on the vehicle manufacturer's guidelines, typically ranging from 30,000 to 100,000 miles.

B. Inspecting Hoses and Components

Periodic inspections of the cooling system hoses, belts, and components are essential to identify potential issues, such as:

Leaks

Cracks

Wear and tear

Addressing these issues promptly can prevent more significant problems and costly repairs.

C. Refilling and Proper Coolant Level

Maintaining the proper coolant level is crucial for efficient cooling system operation. Regularly checking and refilling the coolant reservoir with the recommended mixture can help prevent overheating and ensure optimal performance.

VIII. Conclusion

Proper coolant temperature regulation is essential for maintaining engine performance, efficiency, and longevity. By understanding the roles and functions of the thermostat, radiator, water pump, coolant mixture, and monitoring systems, vehicle owners can ensure their cooling system operates effectively. Regular maintenance, timely component replacements, and addressing any issues promptly are key to avoiding overheating and potential engine damage. By managing this vital temperature regulation process, you can keep your engine running at its best for years to come.

FAQs

What happens if the coolant level is too low?

Having insufficient coolant can lead to overheating and potential engine damage. It's crucial to regularly check and top up the coolant level to maintain proper cooling system operation.

How often should the coolant be flushed and replaced?

The coolant should be flushed and replaced according to the manufacturer's recommended intervals, typically every 30,000 to 100,000 miles or 2 to 5 years.

What are the signs of a failing water pump?

Common signs of a failing water pump include coolant leaks, grinding noises from the pump, and overheating issues due to insufficient coolant circulation.

Can a faulty radiator fan cause overheating?

Yes, a malfunctioning radiator fan can lead to overheating, as it fails to provide adequate airflow for cooling the radiator when the vehicle is stationary or moving slowly.

What is the purpose of the overflow tank?

The overflow tank allows for coolant expansion as it heats up, preventing it from being forced out of the system. It also helps recover any coolant lost through minor leaks or evaporation.

How does the engine computer regulate the cooling system?

The engine computer uses data from the coolant temperature sensors to control components like the radiator fan and water pump speed, ensuring efficient cooling under various driving conditions.

What are the consequences of using the wrong coolant type?

Using an incompatible coolant type can lead to corrosion, scaling, and damage to the cooling system components, potentially causing leaks or complete system failure.

Can a stuck-open thermostat cause issues?

Yes, a stuck-open thermostat can prevent the engine from reaching its optimal operating temperature, leading to decreased efficiency, increased emissions, and poor fuel economy.

What are the signs of a coolant leak?

Signs of a coolant leak include a low coolant level that needs frequent topping up, coolant puddles or stains under the vehicle, and sweet odors from the engine bay.

How can overheating be prevented during extreme driving conditions?

To prevent overheating during extreme conditions like towing or hot weather, it's essential to ensure the cooling system is in good condition, avoid overloading the vehicle, and take frequent breaks to allow the engine to cool down.

Bình luận (0)

Bài viết đề xuất

Maintaining a vehicle's braking system is crucial for ensuring safety on the road. One of the critical components that require regular inspection and timely replacement is the brake lines

The automotive industry is constantly evolving, driven by the pursuit of enhanced performance, efficiency, and sustainability

Spark plugs are essential components that play a crucial role in the operation of gasoline-powered internal combustion engines. They are responsible for igniting the air-fuel mixture within the engine's combustion chamber, initiating the combustion process that powers the vehicle

Bài viết liên quan

An engine cooling system is a crucial component that helps regulate the temperature of an internal combustion engine, preventing overheating and ensuring optimal performance, efficiency, and longevity. This article delves into the inner workings of an engine cooling system, exploring its key components, operation, maintenance, troubleshooting, performance enhancements, and environmental considerations.

Antifreeze is an essential automotive fluid that plays a vital role in maintaining optimal engine temperatures. By leveraging scientific principles, it ensures reliable thermal regulation across various operating conditions. This comprehensive guide delves into the intricate mechanisms behind antifreeze's protective capabilities, exploring its chemistry, formulation, and advanced functionalities.

Corrosion, the gradual deterioration of metals, poses a significant challenge across various industries. Fortunately, corrosion inhibitors offer a powerful solution to mitigate this problem, protecting metallic surfaces and extending the lifespan of critical assets.

Engine coolant, commonly known as antifreeze, plays a vital role in regulating your vehicle's operating temperature. However, like any other automotive fluid, coolant has a limited lifespan and requires periodic replacement to maintain optimal performance and prevent costly repairs. This guide will explore the factors influencing coolant lifespan, the different types of coolants available, and provide practical maintenance recommendations to keep your vehicle running smoothly.