The P0019 diagnostic trouble code indicates a lack of synchronization between the crankshaft position sensor and the camshaft position sensor on the exhaust side (Bank 2 Sensor B) of the engine. Proper timing synchronization is essential for optimal engine operation, fuel efficiency, and emission control. This article will explore the causes, symptoms, diagnostic procedures, and repair methods for the P0019 code, emphasizing the importance of regular maintenance to prevent such issues.

P03E6 - A Camshaft Position Actuator Position Sensor C Range/Performance Bank 1

P03E6 - A Camshaft Position Actuator Position Sensor C Range/Performance Bank 1

Introduction

Diagnostic Trouble Codes (DTCs) are essential for identifying and diagnosing malfunctions in a vehicle's systems. The code P03E6 specifically refers to "A Camshaft Position Actuator Position Sensor C Range/Performance Bank 1." Understanding this code requires a detailed look at the components involved and the potential issues that could trigger this error.

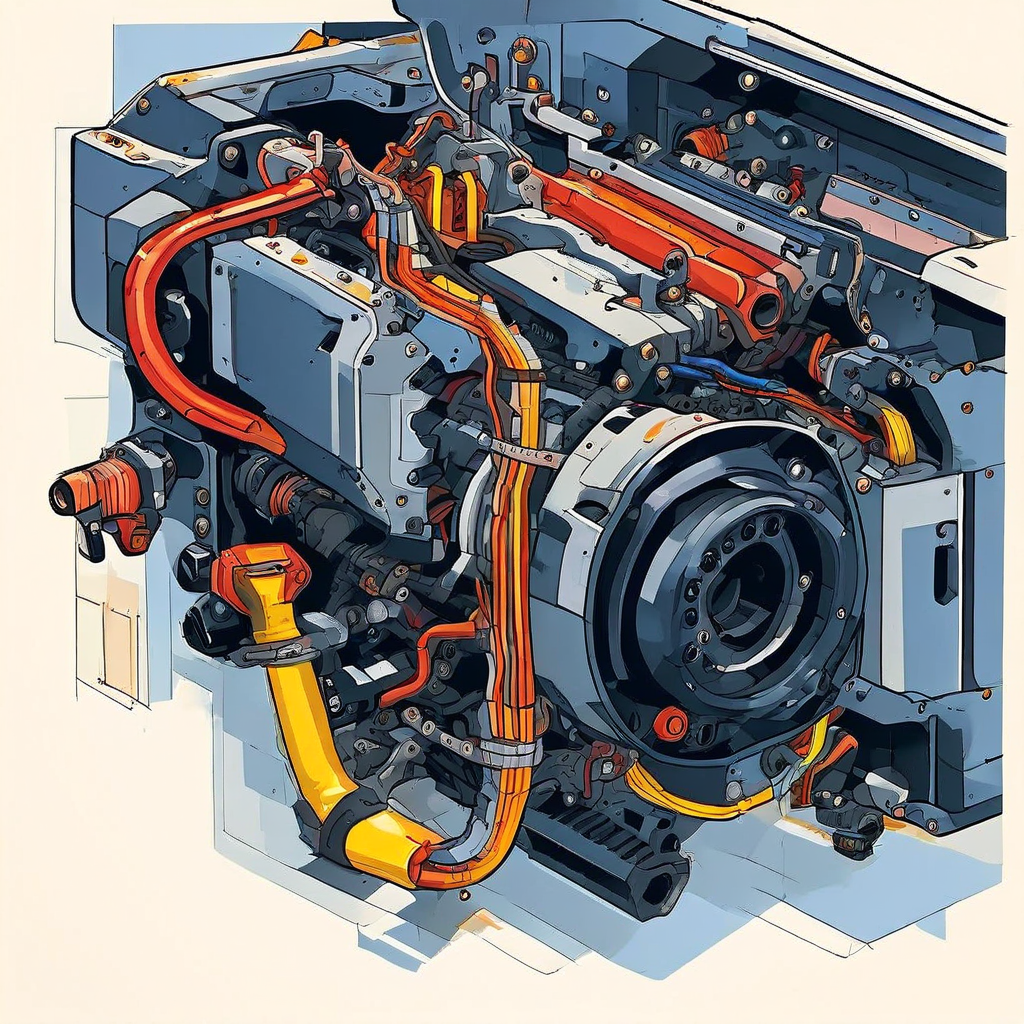

The Camshaft Position Actuator: The Heartbeat of Your Engine

Before we delve into the nitty-gritty of P03E6, let's take a moment to appreciate the unsung hero of your engine – the camshaft position actuator. This ingenious piece of machinery is responsible for controlling the precise timing of your engine's camshaft, which in turn governs the opening and closing of the valves. It's like a choreographer, ensuring that the intricate dance of pistons, valves, and combustion happens in perfect harmony.

| Component | Function |

|---|---|

| Camshaft Position Actuator | Controls the timing of the camshaft, which regulates valve opening and closing |

| Valves | Allow air and fuel mixture into the combustion chamber and exhaust gases out |

| Pistons | Move up and down, compressing the air-fuel mixture and converting the energy from combustion into rotational motion |

Common Causes of P03E6

Now, let's address the elephant in the room – what could possibly trigger the dreaded P03E6 code? Well, my friends, there are a few culprits that we need to keep an eye out for:

The Faulty Sensor: Just like any other component, the camshaft position actuator position sensor can fall victim to wear and tear, or even a manufacturing defect. When this happens, it can send incorrect readings to your engine's computer, causing confusion and triggering the P03E6 code.

Mechanical Mayhem: Sometimes, the issue lies not with the sensor itself but with the camshaft position actuator. If this component becomes stuck or fails to function properly, it can wreak havoc on your engine's timing, leading to the dreaded code.

The Brain of the Operation: Let's not forget about the engine control module (ECM), the mastermind behind your vehicle's performance. If this crucial component encounters software glitches or hardware failures, it might misinterpret the sensor data, resulting in the P03E6 code rearing its ugly head.

| Potential Cause | Description |

|---|---|

| Faulty Sensor | Defective or damaged camshaft position actuator position sensor |

| Mechanical Failure | Stuck or malfunctioning camshaft position actuator |

| ECM Issues | Software glitches or hardware failures in the engine control module |

Diagnosing the Problem: A Mechanic's Toolbox

As a seasoned mechanic, I've learned that proper diagnosis is key to solving any automotive puzzle. When it comes to P03E6, we have a few tricks up our sleeves:

Visual Inspection: Sometimes, the solution is right in front of our eyes. A thorough visual inspection of the wiring harness, sensor, and camshaft position actuator can reveal any obvious signs of damage, corrosion, or sludge buildup.

Scan Tool Diagnosis: Modern scan tools are like having a direct line to your vehicle's brain. By reading live data from the camshaft position actuator position sensor, we can identify any intermittent or erratic readings that might point to a faulty sensor or wiring issue.

Resistance and Voltage Testing: When in doubt, break out the multimeter! Performing resistance tests on the sensor and its wiring can help us pinpoint any open or short circuits, while voltage testing ensures that the sensor is receiving the correct power supply.

Component Testing: If all else fails, we can always swap out the suspected faulty component with a known good one. This helps us isolate the issue and confirm whether the culprit is indeed the sensor or the camshaft position actuator itself.

| Diagnostic Step | Purpose |

|---|---|

| Visual Inspection | Identify visible damage, corrosion, or sludge buildup |

| Scan Tool Diagnosis | Read live sensor data and detect intermittent issues |

| Resistance and Voltage Testing | Check for open/short circuits and proper power supply |

| Component Testing | Isolate the faulty component by swapping with a known good one |

Fixing the Problem: From Sensors to Actuators

Once we've identified the root cause of the P03E6 code, it's time to roll up our sleeves and get to work. Here are the common repair procedures:

Sensor Replacement: If the camshaft position actuator position sensor is confirmed to be the culprit, replacing it with a new one is often the solution. But fear not, my friends, I'll guide you through the proper installation and calibration procedures to ensure a seamless fix.

Wiring Repair: Sometimes, the issue lies not with the sensor itself but with the wiring that connects it to the ECM. In such cases, we'll need to repair or replace the affected wires and connectors, ensuring proper routing and protection for the wiring harness.

Camshaft Position Actuator Replacement: If the camshaft position actuator itself is mechanically failed, we'll need to replace it with a new or remanufactured unit. This process can be a bit more involved, sometimes requiring additional steps like timing chain replacement or even engine disassembly.

ECM Reprogramming or Replacement: In rare cases, the issue might stem from the engine control module itself. If this is the case, we may need to reprogram or replace the ECM, but don't worry, I'll guide you through the process and ensure you get the best possible service from an authorized dealer or repair facility.

| Repair Procedure | Description |

|---|---|

| Sensor Replacement | Replace the faulty camshaft position actuator position sensor |

| Wiring Repair | Repair or replace damaged wires and connectors |

| Actuator Replacement | Replace the mechanically failed camshaft position actuator |

| ECM Reprogramming/Replacement | Reprogram or replace the faulty engine control module |

Preventive Maintenance: The Key to Avoiding P03E6

As the saying goes, "an ounce of prevention is worth a pound of cure." To avoid encountering the dreaded P03E6 code in the future, I highly recommend following these preventive maintenance tips:

Oil Changes and Engine Maintenance: Adhering to the manufacturer's recommended service intervals for oil changes and engine maintenance is crucial. Regular oil changes and proper maintenance can prevent sludge buildup and excessive wear, which can lead to camshaft position actuator issues.

Quality Matters: Always use high-quality engine oil and filters. Cheap alternatives might save you a few bucks upfront, but they can cost you dearly in the long run by contributing to sludge buildup and premature component failure.

Avoid Extreme Conditions: Exposing your engine to extreme conditions or excessive idling can accelerate wear and tear. Treat your vehicle with care, and it will reward you with reliable performance.

Keep It Clean: Regularly inspecting and cleaning the engine bay can ensure proper airflow and cooling, which can help extend the life of your engine components, including the camshaft position actuator and its sensor.

| Preventive Measure | Benefit |

|---|---|

| Regular Oil Changes and Maintenance | Prevents sludge buildup and excessive wear |

| High-Quality Oil and Filters | Reduces sludge and premature component failure |

| Avoiding Extreme Conditions | Minimizes accelerated wear and tear |

| Engine Bay Cleaning | Ensures proper airflow and cooling |

Cost Considerations: Planning Ahead

Now, let's address the elephant in the room – the cost of repairs. While the exact cost can vary depending on the specific cause and the extent of the work required, here are some general estimates to help you plan ahead:

Camshaft Position Actuator Position Sensor Replacement: Expect to pay anywhere from $100 to $300 for parts and labor.

Wiring Repair: Depending on the extent of the damage, wiring repairs can range from $100 to $500.

Camshaft Position Actuator Replacement: This can be a more significant expense, ranging from $500 to $1,500 for parts and labor, and may require additional work like timing chain replacement or engine disassembly.

ECM Reprogramming or Replacement: If the issue lies with the engine control module, you're looking at a cost range of $500 to $1,500, depending on your vehicle and dealer costs.

| Repair Type | Estimated Cost Range |

|---|---|

| Sensor Replacement | $100 - $300 |

| Wiring Repair | $100 - $500 |

| Actuator Replacement | $500 - $1,500 |

| ECM Reprogramming/Replacement | $500 - $1,500 |

Remember, these are just rough estimates, and the best way to get an accurate cost projection is to consult with a professional mechanic who can diagnose the issue specific to your vehicle.

Conclusion

Well, my friends, we've reached the end of our journey through the intricate world of P03E6. While this diagnostic trouble code might seem daunting at first, with the right knowledge and tools, it's just another puzzle waiting to be solved. Remember, preventive maintenance is key to avoiding these issues altogether, but if you do encounter P03E6, don't panic – just follow the diagnostic steps, identify the root cause, and implement the appropriate repair procedures.

As a mechanic, I've learned that every automotive challenge is an opportunity to expand my knowledge and hone my skills. So, embrace the P03E6 code as a chance to deepen your understanding of your vehicle's inner workings, and never stop learning. Happy wrenching, my friends!

FAQs

What is the P03E6 diagnostic trouble code?

The P03E6 code stands for "Camshaft Position Actuator Position Sensor C Range/Performance Bank 1". It indicates an issue with the camshaft position actuator position sensor on the engine's bank 1 (cylinder 1 side).

What are the common causes of the P03E6 code?

The most common causes are a faulty camshaft position actuator position sensor, wiring issues like shorts or open circuits, and a mechanically failed camshaft position actuator.

How can the P03E6 code be diagnosed?

It can be diagnosed through visual inspection, scan tool diagnosis to read live sensor data, resistance and voltage testing of the sensor and wiring, and component testing by swapping the suspected faulty parts.

What are the repair procedures for the P03E6 code?

The repair procedures include replacing the faulty camshaft position actuator position sensor, repairing or replacing damaged wiring, replacing the mechanically failed camshaft position actuator, and in rare cases, reprogramming or replacing the engine control module (ECM).

How can the P03E6 code be prevented from recurring?

It can be prevented by following the manufacturer's recommended service intervals for oil changes and engine maintenance, using high-quality engine oil and filters, avoiding extreme conditions, and regularly inspecting and cleaning the engine bay.

What is the cost range for repairing the P03E6 code?

The cost can range from $100 to $300 for sensor replacement, $100 to $500 for wiring repair, $500 to $1,500 for actuator replacement, and $500 to $1,500 for ECM reprogramming or replacement.

What is the camshaft position actuator?

The camshaft position actuator is a component that controls the precise timing of the engine's camshaft, which governs the opening and closing of the valves.

What is the purpose of the camshaft position actuator position sensor?

The camshaft position actuator position sensor reports the location of the camshaft to the engine control module (ECM) as it spins, allowing the ECM to monitor and adjust the camshaft timing.

What is the difference between Bank 1 and Bank 2 in an engine?

Bank 1 refers to the side of the engine containing cylinder 1, while Bank 2 refers to the opposite side.

What is the role of the engine control module (ECM) in relation to the P03E6 code?

The ECM monitors the camshaft position actuator position sensor signal and sets the P03E6 code if it detects an issue with the sensor or its circuit. In rare cases, a faulty ECM may need to be reprogrammed or replaced.

Bình luận (0)

Bài viết đề xuất

In today's automotive world, choosing the right motor oil is crucial for ensuring optimal engine performance, protection, and longevity. While conventional mineral-based oils have been the industry standard for decades, synthetic motor oils have gained immense popularity due to their superior capabilities.

The P032C code indicates a problem with the Knock/Combustion Vibration Sensor C Circuit Low, also known as Knock Sensor 3 Circuit Low Input (Bank 1). This sensor plays a crucial role in detecting engine knock, a condition that can cause severe engine damage if not addressed promptly.

The Ford F-150 is one of the most popular and iconic pickup trucks on the market, known for its rugged capability and versatility. One of the most common modifications that F-150 owners make is upgrading the exhaust system, not only for performance gains but also for the distinct sound it produces.