The P0019 diagnostic trouble code indicates a lack of synchronization between the crankshaft position sensor and the camshaft position sensor on the exhaust side (Bank 2 Sensor B) of the engine. Proper timing synchronization is essential for optimal engine operation, fuel efficiency, and emission control. This article will explore the causes, symptoms, diagnostic procedures, and repair methods for the P0019 code, emphasizing the importance of regular maintenance to prevent such issues.

P03EA - A Camshaft Profile Actuator Position Sensor B Exceeded Learning Limit

P03EA - A Camshaft Profile Actuator Position Sensor B Exceeded Learning Limit

Introduction

The Diagnostic Trouble Code (DTC) P03EA indicates an issue with the camshaft profile actuator position sensor B, specifically that it has exceeded its learning limit. This code is part of the OBD-II system, which is used to diagnose problems in vehicles.

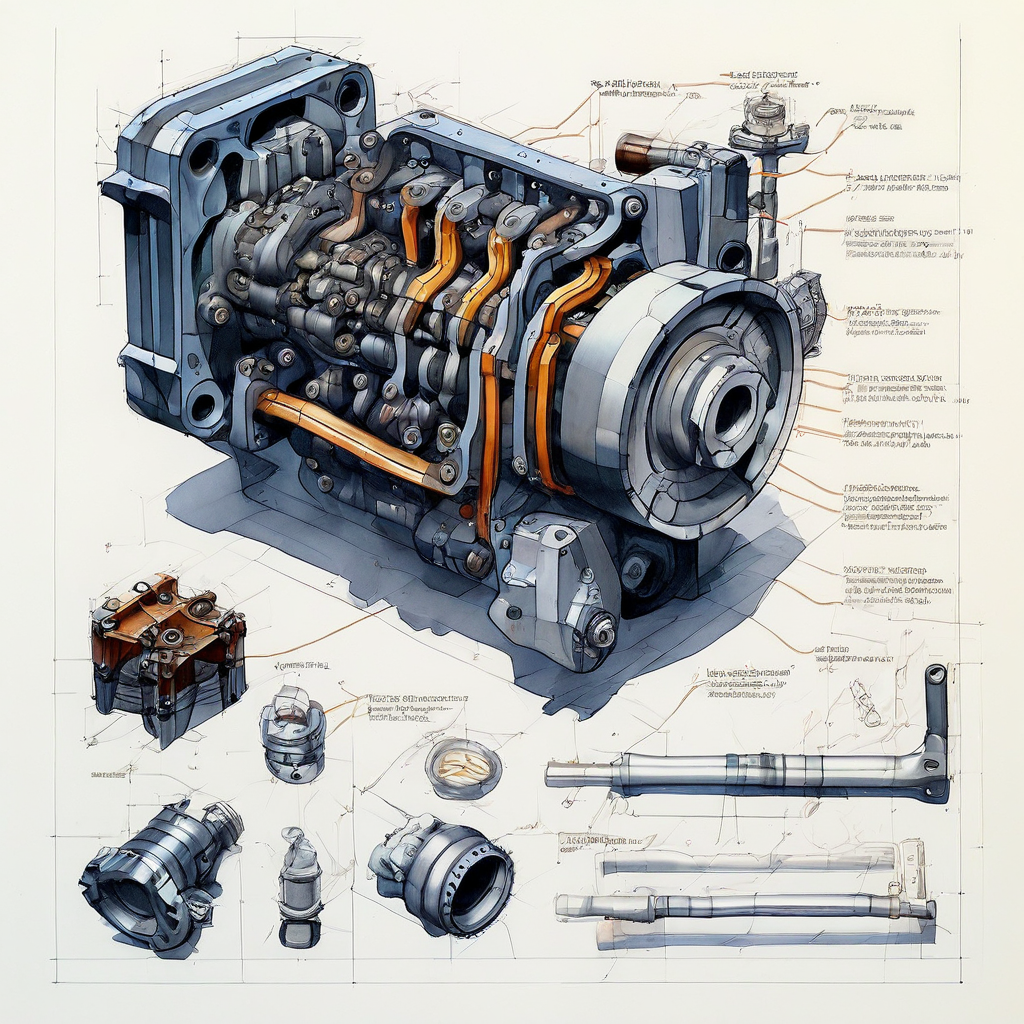

Understanding the Camshaft Position Actuator System

Before we delve into the P03EA code, let's first understand the role of the camshaft position actuator system in your vehicle's engine. This system is responsible for adjusting the timing of the camshaft, which controls the opening and closing of the engine's valves. By optimizing the valve timing, the engine can achieve better fuel efficiency, lower emissions, and improved performance.

The camshaft position actuator, also known as the VVT solenoid, is a crucial component of this system. It receives signals from the engine control module (ECM) and adjusts the camshaft position accordingly. When everything is working as it should, the camshaft position actuator ensures that the valves open and close at the precise moment, allowing for optimal combustion and engine operation.

| Component | Function |

|---|---|

| Camshaft Position Actuator (VVT Solenoid) | Adjusts the camshaft position based on signals from the ECM |

| Engine Control Module (ECM) | Monitors and controls the camshaft position actuator system |

| Camshaft | Controls the opening and closing of the engine's valves |

Causes of the P03EA Code

Now, let's dive into the potential causes that can trigger the P03EA code. As with most diagnostic trouble codes, there are several culprits that could be responsible:

Defective Camshaft Position Actuator Solenoid

The camshaft position actuator solenoid is the heart of the system, and if it's stuck, damaged, or not functioning properly, it can cause the P03EA code to be set.

This could be due to a mechanical failure, electrical issues, or simply wear and tear over time.

Wiring Issues

The camshaft position actuator solenoid is connected to the ECM through a network of wires and connectors.

Any problems with this wiring harness, such as frayed, open, or shorted wires, or corroded connectors, can interfere with the communication between the solenoid and the ECM, resulting in the P03EA code.

Engine Control Module (ECM) Failure

The ECM is the brain of your vehicle's engine management system, and if it's not functioning correctly, it can send incorrect signals to the camshaft position actuator solenoid, causing the P03EA code to be set.

This could be due to a software glitch, a hardware failure, or even a problem with the ECM's power supply or grounding.

Mechanical Issues

In some cases, the P03EA code can be triggered by mechanical issues with the camshaft itself, such as worn lobes or bearings.

These problems can cause the camshaft position actuator to exceed its learning limit, leading to the P03EA code being set.

Diagnosing the P03EA Code

As a mechanic, I always emphasize the importance of proper diagnosis before attempting any repairs. When it comes to the P03EA code, there are several steps you can take to pinpoint the root cause:

Visual Inspection

Start by visually inspecting the camshaft position actuator solenoid and its wiring harness for any signs of damage, corrosion, or loose connections.

This can often provide valuable clues about the source of the problem.

Resistance Test

Using a digital multimeter, you can measure the resistance of the camshaft position actuator solenoid.

By comparing the readings to the manufacturer's specifications, you can identify if the solenoid is faulty or not.

| Resistance Test | Description |

|---|---|

| Multimeter | Used to measure the resistance of the camshaft position actuator solenoid |

| Manufacturer's Specifications | Reference values to compare the measured resistance against |

Circuit Testing

With the help of a multimeter or a scan tool, you can check for proper voltage supply, ground, and control signals to the camshaft position actuator solenoid circuit.

This can help you identify any open or shorted circuits that might be causing the P03EA code.

ECM Testing

If the wiring and solenoid check out, the next step is to perform diagnostic tests on the ECM itself.

This can involve monitoring live data, performing bi-directional control tests, or even checking for software updates or reflashing the ECM's firmware.

Repair and Replacement Procedures

Once you've identified the root cause of the P03EA code, it's time to take action and repair or replace the faulty components. Here are some common repair and replacement procedures:

Camshaft Position Actuator Solenoid Replacement

If the solenoid is found to be defective, it will need to be replaced with a new one.

This process typically involves:

Removing the solenoid from the engine

Disconnecting the wiring harness

Installing the new solenoid according to the manufacturer's instructions

Wiring Repair

If the issue is related to the wiring harness, you'll need to repair or replace any damaged wires, connectors, or grounds.

This can involve:

Splicing in new wires

Replacing connectors

Running a new wiring harness if the damage is extensive

ECM Replacement

In the event that the ECM is found to be faulty, it may need to be replaced or reprogrammed by a professional technician.

This is typically a more complex and costly repair, but it's sometimes necessary to resolve the P03EA code.

Mechanical Repairs

If the root cause is related to mechanical issues with the camshaft itself, such as worn lobes or bearings, you may need to perform more extensive repairs or even replace the camshaft assembly.

Prevention and Maintenance

As with any automotive system, prevention and regular maintenance are key to avoiding costly repairs and ensuring the longevity of your vehicle's components. Here are some tips to help prevent the P03EA code from occurring:

Follow the manufacturer's recommended maintenance schedule for inspecting and replacing the camshaft position actuator solenoid and related components. This can help identify potential issues before they become major problems.

Avoid excessive idling, hard acceleration, or high RPM operation, as these can put additional stress on the camshaft position actuator system and potentially cause premature wear or failure.

Regularly inspect and clean electrical connections, grounds, and wiring harnesses to prevent corrosion or damage that could interfere with the proper operation of the camshaft position actuator system.

| Maintenance Task | Description |

|---|---|

| Follow Manufacturer's Schedule | Regular inspections and replacements of components |

| Proper Driving Habits | Avoid excessive stress on the camshaft position actuator system |

| Electrical System Checks | Inspect and clean connections, grounds, and wiring harnesses |

Cost Considerations

When it comes to repairing the P03EA code, the cost can vary depending on the specific cause and the make and model of your vehicle. Here's a general breakdown of potential costs:

Camshaft Position Actuator Solenoid Replacement

Typically ranges from $100 to $300, plus labor costs.

Wiring Repair

Can vary widely depending on the extent of the damage, but generally falls between $100 and $500, including labor.

ECM Replacement

Often the most expensive repair, with costs ranging from $500 to $1,500 or more, depending on the vehicle and the complexity of the replacement process.

Mechanical Repairs

If mechanical issues with the camshaft are involved, the cost can be significant, potentially reaching thousands of dollars for extensive repairs or camshaft replacement.

It's important to note that regular maintenance and timely repairs can help prevent more expensive repairs in the long run. By addressing issues early on, you can often avoid the need for more costly repairs down the line.

Conclusion

The P03EA code might seem like a complex and daunting issue, but with the right knowledge and approach, it's a challenge that can be overcome. As a mechanic, I've seen firsthand the importance of proper diagnosis, repair, and maintenance when it comes to the camshaft position actuator system.

By understanding the causes, diagnostic procedures, and repair methods, you can take control of this code and ensure that your vehicle's engine continues to operate at its best. Remember, prevention is key, so don't neglect regular maintenance and keep an eye out for any potential issues.

Whether you're a DIY enthusiast or prefer to leave it to the professionals, the knowledge shared in this article will help you navigate the world of the P03EA code with confidence. So, embrace the challenge, and let's keep those engines running smoothly!

FAQs

What does the P03EA code stand for?

The P03EA code stands for "A Camshaft Profile Actuator Position Sensor B Exceeded Learning Limit". It indicates an issue with the camshaft position actuator system.

What is the camshaft position actuator system?

The camshaft position actuator system adjusts the timing of the camshaft, which controls the opening and closing of the engine's valves for optimal performance and efficiency.

What are the common causes of the P03EA code?

Common causes include a defective camshaft position actuator solenoid, wiring issues, engine control module failure, and mechanical problems with the camshaft itself.

How can I diagnose the P03EA code?

Diagnosis involves visual inspection, resistance testing of the actuator solenoid, circuit testing for proper voltage and signals, and testing the engine control module.

What are the repair procedures for the P03EA code?

Repair procedures may include replacing the camshaft position actuator solenoid, repairing or replacing wiring and connectors, replacing the engine control module, or performing mechanical repairs on the camshaft.

How can I prevent the P03EA code from recurring?

Follow the manufacturer's recommended maintenance schedule, avoid excessive idling or high RPM operation, and regularly inspect and clean electrical connections and wiring harnesses.

What are the cost considerations for repairing the P03EA code?

Costs can vary widely depending on the specific cause, but replacing the actuator solenoid may cost $100-$300, while an engine control module replacement can cost $500-$1,500 or more.

Can a faulty VANOS solenoid cause the P03EA code?

Yes, a dirty or defective VANOS (variable valve timing) solenoid can sometimes trigger a camshaft position fault code like P03EA.

What is the difference between the "A" and "B" camshaft position sensors?

The "A" typically refers to the intake camshaft, while the "B" refers to the exhaust camshaft on the same bank.

Can mechanical issues with the camshaft itself cause the P03EA code?

Yes, problems like worn camshaft lobes or bearings can cause the actuator to exceed its learning limit and set the P03EA code.

Bình luận (0)

Bài viết đề xuất

The P003F diagnostic trouble code indicates an issue with the variable valve timing (VVT) system, specifically the camshaft profile actuator for the exhaust camshaft on bank 2 (typically the driver's side bank on V6 and V8 engines). This actuator is responsible for adjusting the valve timing, and when it gets stuck in the "on" position, it can lead to various performance issues and increased emissions.

Anti-lock Braking Systems (ABS) are essential safety features in modern vehicles, helping drivers maintain control during emergency braking situations. However, when ABS components malfunction, repair costs can quickly add up. In this article, we'll explore the factors influencing ABS repair expenses, common issues, and cost-saving strategies to help vehicle owners navigate this complex topic with confidence.

Choosing the right motor oil for your Dodge Charger's 5.7L Hemi V8 engine is a critical decision that can significantly impact its performance, protection, and longevity.