The exhaust manifold is a critical component that plays a pivotal role in optimizing your car's performance, emissions control, and overall efficiency. By upgrading this essential part, you can unlock a world of hidden potential, transforming your driving experience and unleashing the true power of your engine.

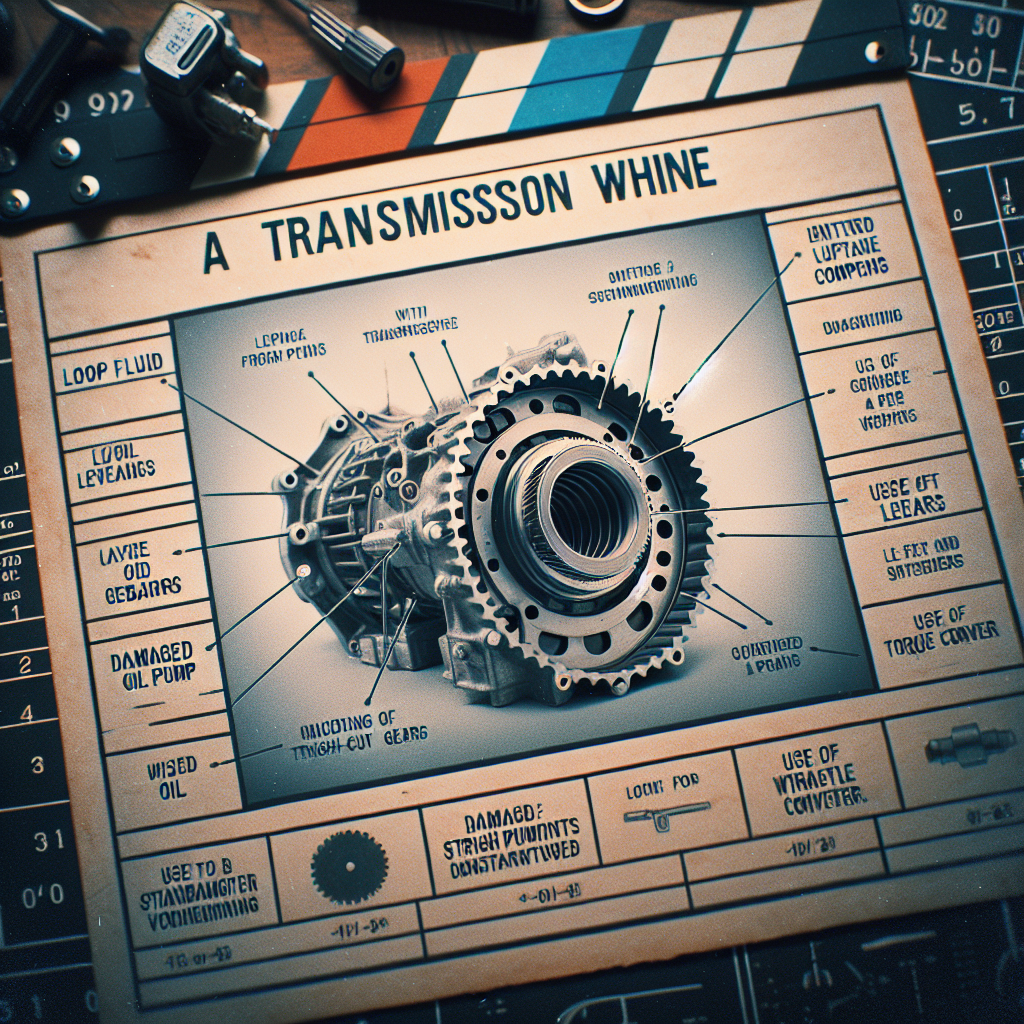

What Causes a Transmission to Whine: Identifying Common Transmission Noises

What Causes a Transmission to Whine: Identifying Common Transmission Noises

Introduction

Transmissions are essential components in vehicles that facilitate the transfer of power from the engine to the wheels, enabling the vehicle to move. They are intricate systems consisting of various components, such as gears, shafts, clutches, and hydraulic systems, working together to provide the necessary torque and speed for efficient operation.

The primary function of a transmission is to adjust the gear ratios between the engine and the wheels, allowing the vehicle to operate efficiently at different speeds. At lower speeds, the transmission provides higher torque to the wheels, enabling the vehicle to accelerate from a standstill or climb inclines. Conversely, at higher speeds, the transmission shifts to lower gear ratios, reducing the engine's revolutions per minute (RPM) and improving fuel efficiency.

Main Causes of Transmission Whining

Transmission whining can stem from various issues within the transmission system. Here are the main culprits:

| Cause | Description |

|---|---|

| Low Transmission Fluid Level | Inadequate fluid levels lead to insufficient lubrication, causing increased friction and whining noises. |

| Worn Bearings or Gears | Over time, the constant stress and friction can wear down bearings and gears, resulting in grinding and whining sounds. |

| Failing Transmission Pump | A failing pump may not provide adequate fluid pressure and flow, starving components of lubrication and causing whining. |

| Clogged Fluid Lines or Filters | Restricted fluid flow due to clogs can prevent proper lubrication, leading to increased friction and whining. |

| Torque Converter Issues | Problems with the torque converter, such as excessive wear or failure, can produce whining sounds during acceleration. |

It's important to note that multiple factors can contribute to transmission whining, and a thorough inspection is necessary to pinpoint the root cause.

Inspection and Diagnosis

Proper diagnosis is crucial before attempting any repairs. Here are the steps I typically take to identify the source of a transmission whine:

Check Transmission Fluid Level and Condition

The first step is to check the transmission fluid level and condition. Low fluid levels or discolored, contaminated fluid can often be the root cause of the whining noise.

If the fluid level is low, topping it up may temporarily resolve the issue, but it's essential to investigate the underlying cause of the fluid loss.

Discolored or contaminated fluid can indicate internal wear or damage, requiring further inspection.

Listen for Changes in Whine Pitch

Listening carefully to the whine and noting any changes in pitch as you accelerate or decelerate can provide valuable clues.

A whine that increases in pitch with engine RPM could indicate worn bearings or gears.

A constant whine may point to issues with the pump.

Note if the Whine is Constant or Intermittent

Paying attention to whether the whine is constant or intermittent can also aid in diagnosis.

A constant whine may suggest a problem with the pump.

An intermittent whine could be indicative of worn gears or bearings that only make noise under certain conditions.

Perform a Transmission Scan

In many cases, a diagnostic scan of the transmission's computer system can reveal error codes or internal faults that the naked eye can't see. This scan can be invaluable in pinpointing the root cause of the whining noise.

Repair Procedures

Once the cause of the transmission whine has been identified, it's time to address the issue. Here are some common repair procedures:

| Repair | Description |

|---|---|

| Fluid and Filter Change | If the whine is caused by contaminated or low fluid levels, a fluid and filter change may resolve the issue. |

| Pump Replacement | If the whine is traced back to a failing transmission pump, the pump will need to be replaced. |

| Bearing or Gear Replacement or Rebuild | Worn bearings or gears may require a partial or full transmission rebuild, involving disassembly, component replacement, and reassembly. |

| Torque Converter Replacement | If the whining noise is caused by a failed torque converter, the converter will need to be replaced, often requiring transmission removal. |

It's important to note that some repairs, such as a transmission rebuild or replacement, can be complex and costly procedures, requiring specialized tools and expertise.

Preventing Recurrence

While repairs can resolve the immediate issue, it's essential to take preventive measures to avoid future transmission whining and extend the life of your vehicle's drivetrain.

Regular Transmission Fluid and Filter Changes

Following the manufacturer's recommended service intervals for transmission fluid and filter changes is crucial.

Fresh fluid and a clean filter can go a long way in reducing friction and wear on internal components.

Avoid Low Fluid Conditions and Overheating

Regularly checking your transmission fluid level and ensuring it's topped up can prevent low fluid conditions that can lead to whining.

Avoid overworking your transmission by towing heavy loads or driving aggressively, as this can cause overheating and accelerated wear.

Use Appropriate Fluids and Additives

Always use the recommended fluid type and viscosity for your vehicle's transmission.

Some manufacturers may also recommend the use of friction modifiers or other additives to enhance the fluid's performance and extend component life.

Cost Considerations

The cost of addressing transmission whining can vary significantly depending on the extent of the issue and the repair procedures required.

| Repair | Typical Cost Range |

|---|---|

| Fluid and Filter Change | $100 - $300 |

| Partial Transmission Rebuild | $1,000 - $3,500 |

| Complete Transmission Replacement | $1,500 - $5,000+ |

It's important to note that these costs are estimates and can vary based on your vehicle's make and model, as well as the complexity of the repair. Additionally, labor costs can vary depending on the region and the repair facility.

While these costs may seem daunting, addressing transmission whining promptly is advisable to prevent further, more expensive damage. Ignoring the issue can lead to complete transmission failure, which would necessitate a costly replacement and potentially leave you stranded on the side of the road.

Conclusion

Transmission whining is a common issue that should never be ignored. As a mechanic, I've seen firsthand how addressing these noises promptly can save drivers from more significant and costly repairs down the line. By understanding the potential causes, performing proper diagnosis, and taking preventive measures, you can extend the life of your transmission and enjoy a smoother, quieter ride for years to come.

Remember, your vehicle's transmission is a complex and vital component, and it's always best to seek the expertise of a qualified mechanic when dealing with issues like whining noises. With the right care and maintenance, your transmission can continue to serve you reliably, mile after mile.

FAQs

Here is an FAQ section with 10 additional questions and answers based on the article content:

What other sounds indicate transmission issues besides whining?

Grinding, clunking, humming, and buzzing noises can also signal transmission problems. These sounds often indicate increased friction or worn components within the transmission.

Can I drive with a whining transmission?

While you can drive for a short period, it's not recommended to continue driving with a whining transmission as it can lead to further, more expensive damage.

How do I check my transmission fluid level?

Consult your owner's manual for the proper procedure, but typically you'll need to start the engine, engage the parking brake, and check the dipstick while the transmission is at operating temperature.

What causes low transmission fluid levels?

Low fluid levels can be caused by leaks, improper fluid changes, or excessive wear on internal components.

Can I replace just the worn bearings or gears?

In some cases, individual components like bearings or gears can be replaced, but often a partial or complete transmission rebuild is necessary.

How long does a transmission rebuild take?

The time required for a transmission rebuild can vary, but it typically takes 1-3 days depending on the extent of the work and the availability of parts.

What is a torque converter and how does it relate to transmission whining?

A torque converter is a fluid coupling that transfers power from the engine to the transmission. A failing torque converter can produce whining noises during acceleration.

How often should I change my transmission fluid?

Follow the manufacturer's recommended service intervals, which is typically every 30,000 to 100,000 miles depending on your vehicle and driving conditions.

Can I use any type of transmission fluid?

No, it's crucial to use the recommended fluid type and viscosity for your specific vehicle and transmission to ensure proper lubrication and performance.

Will a transmission flush resolve whining noises?

A transmission flush may temporarily resolve whining caused by contaminated fluid, but it won't fix issues caused by worn components or other internal damage.

Bình luận (0)

Bài viết đề xuất

The internal combustion engine is a remarkable invention that has revolutionized transportation and industry.

The Ford F-150 is one of the most popular and iconic pickup trucks on the market, known for its rugged capability and versatility. One of the most common modifications that F-150 owners make is upgrading the exhaust system, not only for performance gains but also for the distinct sound it produces.

The Honda 1.5-liter turbocharged engine, introduced in 2016, has garnered attention for its impressive power and fuel efficiency. However, this engine has also been plagued by recurring issues that have raised concerns among owners and mechanics.