Brake linings are a crucial component of a vehicle's braking system, serving as the primary source of friction to slow down and stop the vehicle's motion. When the brake pedal is pressed, the brake linings are forced against the rotating brake drums or discs, creating friction that converts the vehicle's kinetic energy into heat energy, effectively reducing its speed.

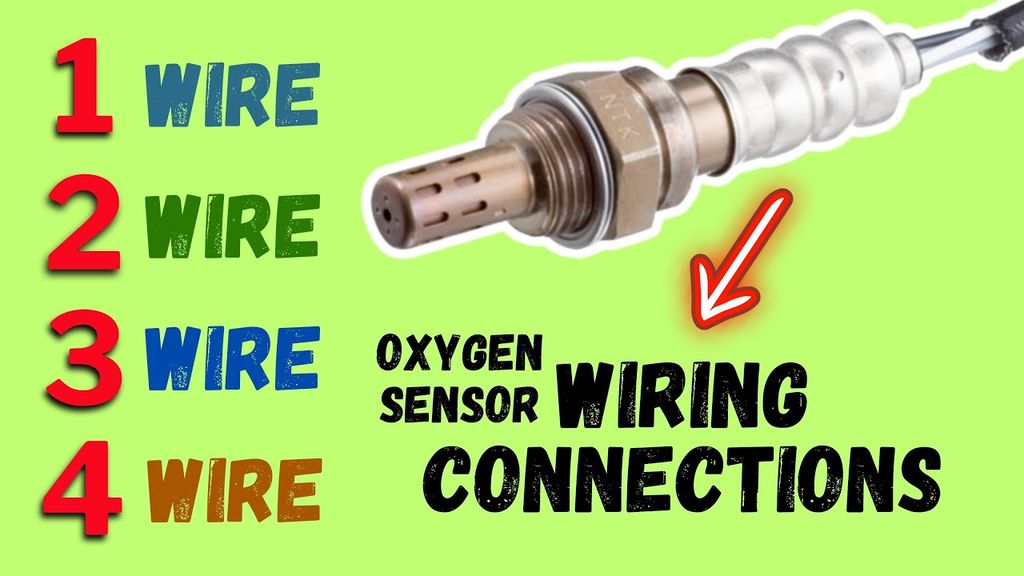

4 Wire Oxygen Sensor Diagram: Wiring O2 Sensors for Peak Performance

4 Wire Oxygen Sensor Diagram: Wiring O2 Sensors for Peak Performance

Oxygen sensors are vital components in a vehicle's fuel management system, responsible for monitoring exhaust gas composition and optimizing the air-fuel ratio for efficient combustion. This comprehensive guide will explore the intricacies of 4 wire oxygen sensor wiring diagrams, their functions, proper placement, and troubleshooting techniques to ensure your engine runs at peak performance.

Understanding 4 Wire Oxygen Sensors

Oxygen sensors, also known as O2 sensors or lambda sensors, are small devices installed in a vehicle's exhaust system that measure the amount of unburned oxygen in the exhaust gases. The information collected by the sensor is sent to the engine control unit (ECU), which adjusts the air-fuel mixture to achieve optimal combustion efficiency, fuel economy, and reduced emissions.

| Sensor Type | Description |

|---|---|

| Zirconia | Uses a zirconia ceramic sensing element that generates a voltage signal based on the difference in oxygen levels between the exhaust gas and outside air. |

| Titania | Employs a titania ceramic sensing element that changes resistance based on the exhaust gas oxygen content. |

| Wideband | Advanced sensors that can accurately measure a wider range of air-fuel ratios compared to traditional narrowband sensors, providing more precise feedback to the ECU. |

Oxygen sensors are housed in a protective metal shell with a ceramic insulator and connected to the wiring harness via a 4 wire connector. Wideband sensors are commonly found in modern vehicles with direct fuel injection and turbocharged engines, offering improved fuel management.

4 Wire Oxygen Sensor Wiring

A typical 4 wire oxygen sensor wiring diagram consists of the following components:

White wire : Carries the oxygen sensor's voltage signal to the ECU, indicating the exhaust gas composition. The signal typically ranges from 0.1V (lean mixture) to 0.9V (rich mixture), with 0.45V representing the stoichiometric air-fuel ratio of 14.7:1.

Gray wire : Serves as the signal ground, providing a reference point for the sensor's voltage output. It connects to a dedicated ground point on the vehicle's chassis or engine block.

Black wires : Responsible for powering the oxygen sensor's internal heater element. One wire supplies 12V power from a switched source, while the other serves as the heater ground. The heater maintains the sensor at its optimal operating temperature (around 600°F or 315°C) for accurate readings, especially during cold starts and low-load conditions.

It's crucial to note that wire colors may vary between vehicle makes and models, so always refer to the specific wiring diagram for your vehicle when working with oxygen sensors. A faulty heater circuit can lead to delayed response times, inaccurate readings, and reduced fuel efficiency.

Oxygen Sensor Placement

Oxygen sensors are strategically placed in the exhaust system to monitor the air-fuel ratio at different stages:

Upstream (pre-catalytic) sensors : Located before the catalytic converter, providing real-time feedback to the ECU for fuel trim adjustments. Most vehicles have at least one upstream sensor, while some may have two (one for each bank of cylinders in a V-configuration engine).

Downstream (post-catalytic) sensors : Positioned after the catalytic converter, monitoring the converter's efficiency by comparing oxygen levels before and after the converter. Similar readings between upstream and downstream sensors indicate a failing catalytic converter.

Proper sensor placement is essential for accurate readings and efficient engine management. When installing a new oxygen sensor, ensure the threads are clean and undamaged, and tighten the sensor to the manufacturer's specified torque value (typically 30-44 ft-lbs) to prevent exhaust leaks.

Oxygen Sensor Troubleshooting

Over time, oxygen sensors can fail due to contamination, physical damage, or normal wear and tear. Common symptoms of a failing oxygen sensor include:

Poor fuel economy

Rough idle or misfires

Check Engine Light (CEL) illumination with O2 sensor-related trouble codes

Failed emissions test

To diagnose a suspected oxygen sensor issue, follow these testing procedures:

Voltage tests : Measure the sensor's voltage output using a digital multimeter while the engine is running. A properly functioning sensor should fluctuate between 0.1V and 0.9V, with a steady 0.45V at idle indicating a stoichiometric air-fuel ratio.

Resistance tests : Disconnect the sensor and measure the resistance between the heater wires (black wires) using an ohmmeter. Compare the readings to the manufacturer's specifications, typically ranging from 2 to 30 ohms.

Heater current tests : With the sensor connected and the engine running, use an inductive ammeter to measure the current draw of the heater circuit. A functioning heater should draw between 0.5 to 2 amps, depending on the sensor type and vehicle application.

Interpreting sensor waveforms on a scan tool or oscilloscope can provide valuable insights into the sensor's performance. A healthy sensor should display a rapidly fluctuating waveform, crossing the 0.45V threshold as the ECU adjusts the fuel mixture. A flat line or slow-responding waveform indicates a faulty sensor. Contamination from engine oil, coolant, or silicone sealants can cause premature sensor failure. If contamination is suspected, clean the sensor with a specialized cleaner or replace it entirely to restore proper function.

Replacing Oxygen Sensors

Oxygen sensors should be replaced according to the manufacturer's recommended service interval, typically every 60,000 to 100,000 miles, or when diagnosed as faulty. When selecting a replacement sensor, consider the following factors:

OEM vs. aftermarket : Original Equipment Manufacturer (OEM) sensors are designed to meet the vehicle's specific requirements and often have better quality control. Aftermarket sensors can be a cost-effective alternative but may have varying quality and performance.

Heated vs. unheated : Most modern vehicles use heated oxygen sensors for faster response times and improved accuracy. Ensure that the replacement sensor has the correct heater specifications for your vehicle.

Wideband upgrades : If your vehicle is equipped with narrowband sensors, upgrading to wideband sensors can provide more precise air-fuel ratio control and improved engine performance. However, this may require additional modifications to the ECU and wiring harness.

To replace an oxygen sensor:

Disconnect the negative battery cable to prevent electrical shorts.

Locate the faulty sensor and disconnect the electrical connector.

Remove the old sensor using an oxygen sensor socket or wrench.

Clean the sensor port threads and apply a small amount of anti-seize compound to the new sensor's threads.

Install the new sensor and tighten it to the manufacturer's specified torque value.

Reconnect the electrical connector and negative battery cable.

After replacing an oxygen sensor, the ECU may need to relearn the new sensor's characteristics through a process called adaptation. This can be done by driving the vehicle under various operating conditions (idle, acceleration, deceleration, and steady cruising) for several minutes to allow the ECU to adjust the fuel trims accordingly.

Preventing Oxygen Sensor Problems

To extend the life of your oxygen sensors and prevent premature failure, follow these maintenance tips:

Regular maintenance : Adhere to the manufacturer's recommended service schedule for oil changes, air filter replacements, and spark plug maintenance to ensure clean and efficient combustion.

Avoiding contamination : Address any oil or coolant leaks promptly to prevent sensor contamination. Use silicone-free sealants and gaskets when working on the exhaust system to avoid damaging the sensor's ceramic element.

Addressing fuel trim issues : Monitor long-term fuel trim (LTFT) values using a scan tool. Values exceeding ±10% indicate a potential issue with the air-fuel ratio, which can be caused by a faulty oxygen sensor, vacuum leaks, or fuel system problems.

Clearing codes and retesting : After replacing an oxygen sensor or addressing related issues, clear any stored trouble codes and retest the system to ensure proper operation. If the codes return or the sensor continues to malfunction, further diagnosis may be necessary.

| Sensor Specifications | Zirconia | Titania | Wideband |

|---|---|---|---|

| Voltage Range | 0.1V - 0.9V | 0.1V - 0.9V | 0V - 5V |

| Heater Resistance | 2 - 15 ohms | 5 - 30 ohms | 2 - 10 ohms |

| Response Time | 50 - 100 ms | 100 - 200 ms | 10 - 50 ms |

Conclusion

Properly functioning oxygen sensors are essential for maintaining optimal engine performance, fuel efficiency, and emissions control. Understanding the 4 wire oxygen sensor wiring diagram, sensor placement, and troubleshooting techniques empowers you to effectively diagnose and resolve issues related to these critical components. Regular maintenance, prompt attention to fault codes, and timely replacement of faulty sensors will ensure that your vehicle's fuel management system operates at peak efficiency, saving you money at the pump and keeping your engine running smoothly for years to come.

FAQs

What are the most common symptoms of a failing oxygen sensor?

Common symptoms include poor fuel economy, rough idle, misfires, and a check engine light. A faulty O2 sensor can cause incorrect air-fuel mixture adjustments, leading to these drivability issues.

How often should oxygen sensors be replaced?

Oxygen sensors typically last between 60,000 to 100,000 miles, depending on the vehicle and driving conditions. It's best to follow the manufacturer's recommended replacement interval or replace them when diagnosed as faulty.

Can a malfunctioning oxygen sensor cause a vehicle to fail an emissions test?

Yes, a faulty oxygen sensor can lead to an imbalance in the air-fuel ratio, resulting in higher emissions levels. This can cause a vehicle to fail an emissions test and trigger a check engine light.

What is the difference between a narrowband and wideband oxygen sensor?

Narrowband sensors can only detect a narrow range of air-fuel ratios around the stoichiometric point (14.7:1), while wideband sensors can accurately measure a wider range of ratios. Wideband sensors provide more precise feedback to the ECU for better fuel management.

Can a dirty or contaminated oxygen sensor be cleaned, or must it be replaced?

In most cases, a contaminated oxygen sensor should be replaced rather than cleaned. Attempting to clean the sensor may damage the delicate ceramic element and compromise its performance. It's more reliable and cost-effective to install a new sensor.

What are the most common causes of oxygen sensor failure?

The most common causes of O2 sensor failure include age and high mileage, contamination from engine oil, coolant, or silicone sealants, and electrical issues in the heater circuit. Exposure to harsh exhaust gases and extreme heat can also degrade sensor performance over time.

Can a faulty oxygen sensor cause poor fuel economy?

Yes, a malfunctioning oxygen sensor can lead to incorrect air-fuel mixture adjustments, resulting in reduced fuel efficiency. The ECU may compensate by enriching the mixture, causing the engine to consume more fuel than necessary.

What tools are needed to replace an oxygen sensor?

To replace an oxygen sensor, you'll need a socket wrench with an oxygen sensor socket, a ratchet, and possibly an extension bar. A wire brush or thread chaser can help clean the sensor port threads, and a small amount of anti-seize compound should be applied to the new sensor's threads.

How do I know if my vehicle has narrowband or wideband oxygen sensors?

Consult your vehicle's owner's manual or a repair manual to determine the type of oxygen sensors installed. Generally, newer vehicles with direct fuel injection and turbocharged engines are more likely to have wideband sensors, while older vehicles typically use narrowband sensors.

Can a malfunctioning oxygen sensor cause a vehicle to run rich or lean?

Yes, a faulty oxygen sensor can send incorrect signals to the ECU, causing it to adjust the air-fuel mixture improperly. This can result in either a rich (too much fuel) or lean (too little fuel) condition, affecting engine performance, fuel economy, and emissions.

Bình luận (0)

Bài viết đề xuất

Spark plugs are a crucial component in gasoline-powered internal combustion engines, responsible for igniting the air-fuel mixture and enabling the combustion process.

As an experienced mechanic, I've encountered countless cases of engine oil sludge buildup, and let me tell you, it's a problem that can wreak havoc on your vehicle's performance and longevity.

Adopting safe and efficient driving habits is crucial for every driver on the road. Two key areas to focus on are avoiding aggressive braking and reducing towing loads. By mastering these techniques, you can enhance your vehicle's performance, improve fuel economy, and prioritize the safety of yourself and others.