Automotive exhaust systems play a crucial role in managing emissions and ensuring optimal vehicle performance. Among the various materials used in their construction, aluminized steel has emerged as a popular choice, offering a compelling balance of corrosion resistance, durability, and cost-effectiveness

Corroded Condenser: Causes, Prevention, and Repair Tips for Longevity"

Corroded Condenser: Causes, Prevention, and Repair Tips for Longevity"

Introduction

Condensers are a crucial component of air conditioning and refrigeration systems, responsible for dissipating heat from the refrigerant. They play a vital role in the overall efficiency and performance of these systems.

Understanding the Causes

Condenser corrosion can stem from various factors, but the main culprits are exposure to moisture, corrosive environments, lack of maintenance, and physical damage. Let's explore these causes in detail:

| Cause | Description |

|---|---|

| Moisture Exposure | Prolonged exposure to ambient moisture can initiate rusting. Water accumulating on the coils for extended periods creates the perfect breeding ground for corrosion. |

| Corrosive Environments | Installation in areas with heavy pollutants, chemicals, or near saltwater significantly increases the risk of corrosion. These harsh environments can accelerate the deterioration of the condenser's protective coatings, leaving the underlying metal vulnerable. |

| Lack of Maintenance | Inadequate or infrequent maintenance leads to dirt, debris, and moisture buildup on the condenser, creating a rust-prone environment. |

| Physical Damage | Dents, scratches, or other physical harm can breach the condenser's protective coating, exposing the underlying metal to rusting. Even minor damage can lead to corrosion if left unaddressed. |

Inspection and Diagnosis

As a mechanic, I follow a systematic approach to inspect and diagnose condenser corrosion:

Visual Inspection

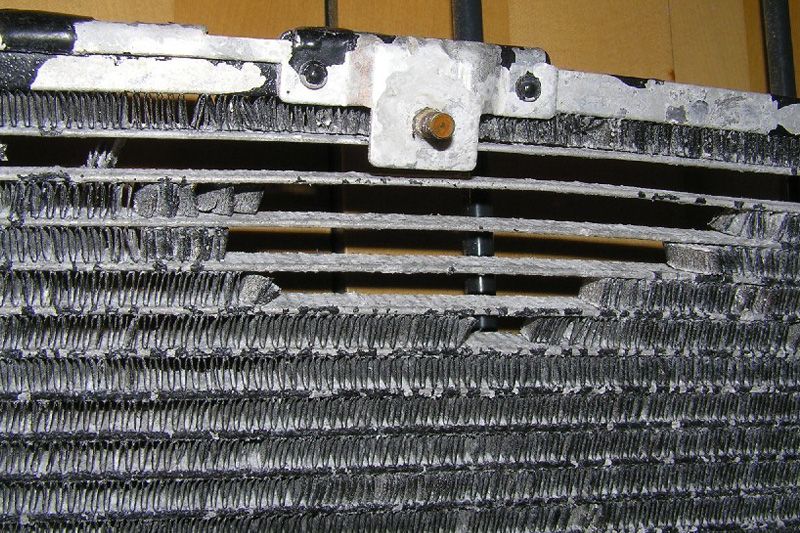

Thorough inspection of the condenser's surface for signs of corrosion, leaks, or missing/deteriorated fins.

Checking the bottom part of the condenser where tubes and fins are most exposed to moisture and salt spray.

Identifying Corrosion Types

Pitting corrosion: Cavities or pits on the metal surface of the coil.

Formicary corrosion: Pinhole leaks or distinct etching on the metal surface.

Leaking condenser: Refrigerant leaks or missing/deteriorated fins.

Checking for Deposits

White/yellow deposits (iron sulfate) on carbon steel surfaces.

Green deposits (nickel sulfate) on stainless steel, indicating corrosion.

Repair Instructions

Once the cause and extent of corrosion are identified, the repair process can begin:

Rust Removal Process

Inspection to assess rust severity and identify structural issues.

Use rust removers, converters, or abrasion methods to eliminate rust, taking care not to damage components.

Apply protective coating or paint after rust removal.

Inspect and replace damaged internal parts like coils or fins if needed.

Cleaning and Maintenance Tips

| Tip | Description |

|---|---|

| Cleaning | Use non-acid foaming coil cleaners and low-pressure water to clean corroded fins without opening passages. Avoid abrasive cleaners or those containing chemicals that can corrode coils. |

| Maintenance | Replace receiver drier during compressor replacement or if system was exposed to air. Ensure no flushing agent residues remain after system flush. |

Preventing Recurrence

While repairs can address existing corrosion, prevention is key to extending the condenser's lifespan:

Regular maintenance: Schedule professional HVAC maintenance to inspect for rust/corrosion and clean coils thoroughly.

Proper usage and operation:

Consider installing a shelter or enclosure to protect the condenser from harsh weather.

Choose a strategic location during installation to limit exposure to corrosive surroundings.

Rinse outdoor unit with a hose monthly to limit debris buildup.

Install whole-house air cleaner to capture airborne VOCs that can cause corrosion.

Use recommended oils, additives, and choose condensers with corrosion-resistant coatings when replacing.

Cost Considerations

The cost of repairing a corroded condenser can vary significantly depending on the extent of the damage and the specific repairs needed:

| Repair Type | Cost Range |

|---|---|

| Minor repairs (cleaning, straightening fins) | $150 to $500 |

| Condenser coil replacement | $800 to $2,800 (not including labor costs) |

| Entire outdoor unit or HVAC system replacement | Several thousand dollars |

In some cases, if the condenser is severely corroded or the damage is extensive, it may be more cost-effective to replace the entire outdoor unit or HVAC system.

Conclusion

Condenser corrosion is a common issue that can significantly impact the performance and lifespan of a vehicle's air conditioning system. As a mechanic, I've seen firsthand the importance of proper maintenance, timely repairs, and preventive measures to address this problem.

By understanding the causes, recognizing the signs, and following the appropriate repair and prevention steps, you can keep your condenser in top condition and avoid costly replacements down the line. Remember, a little proactive care can go a long way in ensuring your vehicle's air conditioning system runs smoothly for years to come.

FAQs

What are the most common signs of condenser corrosion?

Reduced cooling efficiency and uneven cooling throughout the vehicle are common signs of condenser corrosion. Unusual noises coming from the condenser unit can also indicate corrosion-related issues.

How can a mechanic diagnose condenser corrosion?

A mechanic can diagnose condenser corrosion through a visual inspection, identifying corrosion types like pitting or formicary corrosion, and checking for deposits on the metal surfaces.

What is the process for removing rust from a corroded condenser?

The rust removal process involves assessing the rust severity, using rust removers or abrasion methods to eliminate rust, applying protective coatings, and replacing damaged internal parts if needed.

What cleaning methods are recommended for corroded condensers?

Non-acid foaming coil cleaners and low-pressure water are recommended for cleaning corroded fins without opening passages. Abrasive or chemical cleaners that can further corrode the coils should be avoided.

How can a mechanic prevent future condenser corrosion?

Regular professional maintenance, proper usage and operation, installing shelters or enclosures, choosing strategic locations, and using recommended oils and corrosion-resistant coatings can help prevent future condenser corrosion.

What is the cost range for repairing a corroded condenser?

The cost range for repairing a corroded condenser can vary from $150 to $500 for minor repairs, $800 to $2,800 for coil replacement (not including labor), or several thousand dollars for replacing the entire outdoor unit or HVAC system.

Can condenser corrosion be caused by physical damage?

Yes, physical damage like dents, scratches, or other harm can breach the condenser's protective coating, exposing the underlying metal to rusting and leading to corrosion if left unaddressed.

What role does maintenance play in preventing condenser corrosion?

Inadequate or infrequent maintenance leads to dirt, debris, and moisture buildup on the condenser, creating a rust-prone environment. Regular maintenance is crucial for preventing condenser corrosion.

Are there any specific environments that can accelerate condenser corrosion?

Yes, installation in areas with heavy pollutants, chemicals, or near saltwater can significantly increase the risk of condenser corrosion due to the harsh and corrosive environments.

What steps can a mechanic take to ensure proper condenser maintenance?

A mechanic can recommend regular professional HVAC maintenance, proper usage and operation guidelines, and the installation of protective measures like shelters or enclosures to ensure proper condenser maintenance and prevent corrosion.

Bình luận (0)

Bài viết đề xuất

Coolant hoses are an indispensable part of a vehicle's cooling system, responsible for transporting coolant between the engine and radiator. These hoses must be able to withstand high temperatures, pressure, and exposure to various coolants and chemicals. This article explores the different types of coolant hoses, their materials, characteristics, and applications, providing a comprehensive understanding of this essential automotive component.

The diagnostic trouble code (DTC) P03CE indicates an issue with the pressure variation in cylinder 6 of the engine. Specifically, it means that the pressure variation in cylinder 6 is lower than expected. This code is related to the cylinder pressure monitoring system, which is designed to detect abnormal combustion conditions in each cylinder.

Charging a car battery at home is a simple process that can save you time and money. With the right equipment and safety measures, you can maintain your battery's health and extend its lifespan. This guide will walk you through the steps to charge your car battery properly, helping you avoid costly mistakes and keep your vehicle running smoothly.

Bài viết liên quan

The air conditioning condenser is an essential component of the system, responsible for releasing the heat absorbed from the indoor air. It is typically located outside the building and consists of a coil and a fan.