In the ever-evolving world of cycling, the debate between disc brakes and rim brakes has been a topic of intense discussion. As technology advances and riders demand better performance, the choice between these two braking systems has become increasingly crucial.

Damaged Wiring or Electrical Connections in HVAC Cars: A Comprehensive Guide

Damaged Wiring or Electrical Connections in HVAC Cars: A Comprehensive Guide

Introduction

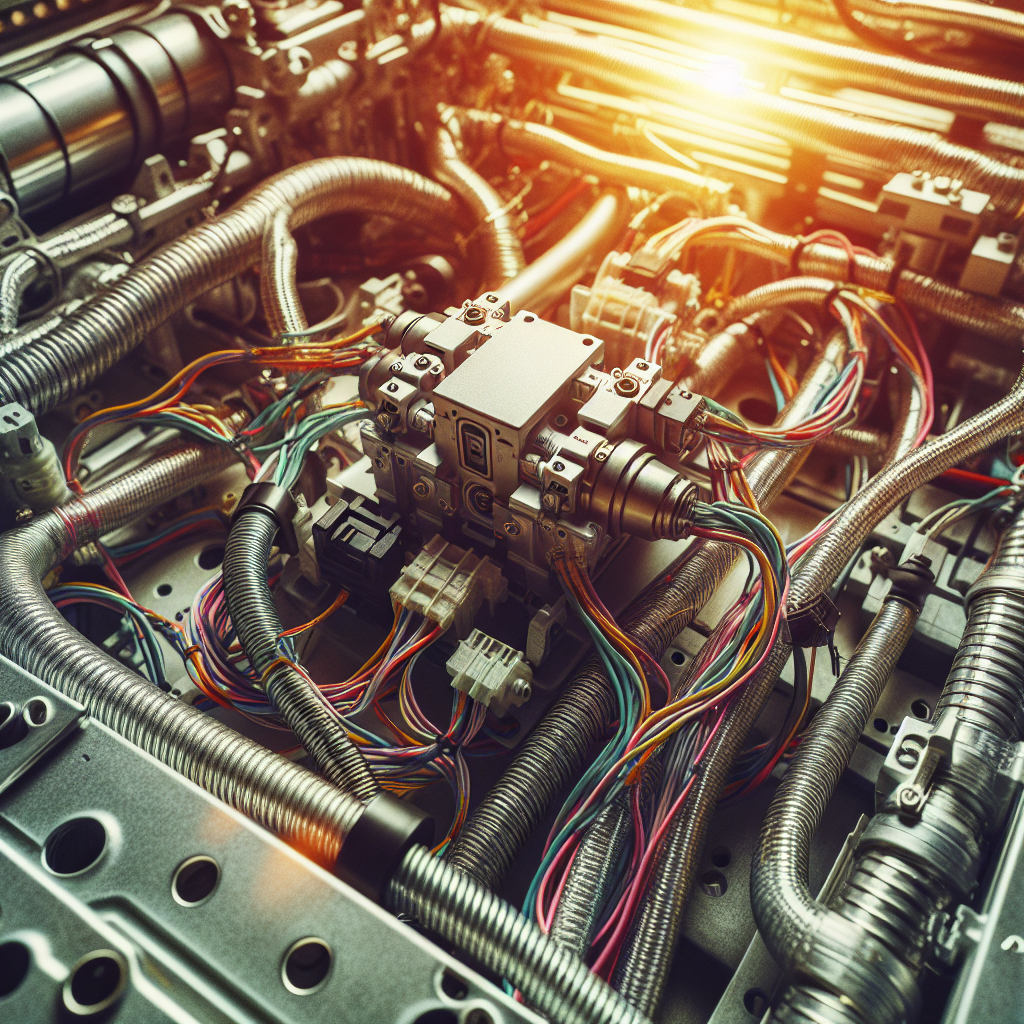

Electrical wiring and connections play a crucial role in the proper functioning of a car's heating, ventilation, and air conditioning (HVAC) system. These components are responsible for transmitting power and signals to various parts of the HVAC system, such as the compressor, fans, and control modules. Damaged wiring or electrical connections can lead to a range of issues, from minor inconveniences to complete system failure.

Main Causes

Damaged wiring, loose connections, corroded terminals, and faulty electrical components are among the most common culprits behind HVAC system failures in cars. Let's delve into the details of each cause:

| Cause | Description |

|---|---|

| Damaged Wiring | Over time, the insulation on wires can become cracked, frayed, or chewed by rodents, exposing the bare wire and causing short circuits or electrical failures. |

| Loose Connections | Vibrations from driving can cause electrical connections to become loose, disrupting the flow of electricity and preventing components from receiving power. |

| Corroded Terminals | Exposure to moisture and heat can lead to corrosion buildup on electrical terminals, creating resistance and preventing proper electrical contact. |

| Faulty Electrical Components | Components like relays, switches, and control modules can fail due to age, heat exposure, or electrical surges, causing the HVAC system to malfunction. |

Inspection and Diagnosis

As a mechanic, I follow a systematic approach to inspect and diagnose HVAC system issues related to wiring and electrical connections. Here are the steps I take:

Inspection Steps

Visually inspect wiring harnesses for signs of damage, such as cracks, frays, or chewed insulation.

Check electrical connections for looseness, corrosion, or signs of overheating.

Test electrical components like relays, switches, and control modules using a multimeter or by swapping with known good parts.

Check for proper voltage and ground at various points in the system.

Signs of Specific Damage

During the inspection process, I look for specific signs that can indicate the type of damage present:

| Sign | Potential Damage |

|---|---|

| Exposed bare wires, melted insulation, or brittle and cracked wires | Damaged wiring |

| Flickering lights, intermittent operation, or components not receiving power | Loose connections |

| Green or white powdery buildup on terminals, difficulty removing connectors | Corroded terminals |

| Components not functioning properly, unusual noises, or burning smells | Faulty electrical components |

Repair Instructions

Once the issue has been identified, I proceed with the appropriate repair procedures:

Wiring Repair

Locate and replace damaged sections of wiring, using the proper wire gauge and insulation.

Secure new wiring using cable ties or looms to prevent future damage from vibrations or exposure.

Connection Repair

Clean corroded terminals using a wire brush or electrical contact cleaner to restore proper electrical contact.

Tighten loose connections or replace connectors if necessary to ensure a secure electrical connection.

Component Replacement

Follow the manufacturer's instructions for removing and replacing faulty electrical components, such as relays, switches, or control modules.

Ensure proper grounding and secure connections when installing new components to prevent future issues.

Tips and Precautions

Disconnect the negative battery cable before working on electrical systems to prevent short circuits or electrical shocks.

Use proper tools and techniques to avoid damaging wiring or components during the repair process.

Label or document wiring connections before disconnecting them to ensure proper reassembly.

Preventing Recurrence

To prevent future issues with your car's HVAC system, regular maintenance and proper usage are crucial:

Regular Maintenance

Inspect wiring harnesses and electrical connections during routine maintenance for any signs of damage or looseness.

Clean and protect electrical connections using dielectric grease or other protective coatings to prevent corrosion.

Proper Usage and Operation

Avoid exposing the HVAC system to excessive moisture or heat, as these conditions can accelerate the degradation of wiring and electrical components.

Secure loose wiring or components that may become damaged by vibrations during driving.

Cost Considerations

The cost of repairing damaged wiring or electrical connections in a car's HVAC system can vary depending on the extent of the damage and the specific components involved. Here's a general breakdown:

| Repair Type | Estimated Cost Range |

|---|---|

| Minor repairs (e.g., replacing a few feet of wiring, tightening loose connections) | $100 - $300 |

| Extensive repairs (e.g., replacing a wiring harness or control module) | $500 - $1,500 or more |

Please note that these cost estimates are approximate and may vary based on the make and model of the vehicle, as well as the labor involved.

Conclusion

As an automotive mechanic, I understand the frustration that comes with a malfunctioning HVAC system. By addressing damaged wiring, loose connections, corroded terminals, and faulty electrical components, we can restore the comfort and functionality of your car's climate control system. Regular maintenance and proper usage can help prevent these issues from recurring, ensuring a pleasant driving experience for years to come.

Throughout this article, I've provided detailed information on the causes, inspection and diagnosis processes, repair instructions, and preventive measures for HVAC system issues related to wiring and electrical connections. By following these guidelines and seeking professional assistance when needed, you can keep your car's HVAC system in top condition and enjoy a comfortable driving experience, regardless of the weather conditions.

FAQs

What are the most common signs of damaged wiring in an HVAC system?

Exposed bare wires, melted insulation, and brittle or cracked wires are common signs of damaged wiring. Flickering lights or components not receiving power can also indicate wiring issues.

How can loose connections affect the HVAC system?

Loose connections can disrupt the flow of electricity, preventing components from receiving power properly. This can cause intermittent operation or complete failure of the HVAC system.

What causes corrosion on electrical terminals?

Exposure to moisture and heat over time can lead to corrosion buildup on electrical terminals, creating resistance and preventing proper electrical contact.

How do you test for faulty electrical components?

Faulty components like relays, switches, and control modules can be tested using a multimeter or by swapping them with known good parts to isolate the issue.

What tools are needed for inspecting and repairing HVAC wiring issues?

Common tools needed include a multimeter, wire brush, electrical contact cleaner, cable ties, proper wiring, and connectors matching the vehicle's specifications.

How can you prevent future wiring damage in the HVAC system?

Regular inspections, securing loose wiring, and using protective coatings like dielectric grease can help prevent future wiring damage and corrosion.

What safety precautions should be taken when working on electrical systems?

Always disconnect the negative battery cable to prevent short circuits or electrical shocks before working on electrical systems.

Can moisture exposure damage HVAC electrical components?

Yes, excessive moisture exposure can accelerate the degradation of wiring insulation and electrical components, leading to potential failures.

How much does it typically cost to repair HVAC wiring issues?

Minor repairs like replacing a few feet of wiring or tightening connections may cost $100-$300, while extensive repairs like replacing a wiring harness can cost $500-$1,500 or more.

Why is it important to follow the manufacturer's instructions during repairs?

Following the manufacturer's instructions ensures proper removal, installation, and grounding of electrical components, preventing further damage or issues.

Bình luận (0)

Bài viết đề xuất

The charging system is a critical component in your Toyota RAV4, responsible for supplying power to the electrical components and keeping the battery charged. When the "Charging System Malfunction" warning illuminates, it indicates an issue that requires prompt attention to prevent further complications.

Autonomous Emergency Braking (AEB) technology has emerged as a game-changer in the realm of vehicle safety, holding the potential to dramatically reduce the occurrence and severity of collisions on our roads. By leveraging an intricate network of sensors and advanced algorithms, AEB systems can identify impending collisions and automatically engage the brakes, even in situations where the driver is unable to react in time. This article will provide an in-depth exploration of the inner workings of AEB, its numerous benefits, real-world performance data, integration with other advanced driver assistance systems (ADAS), regulatory requirements, and industry adoption trends. Furthermore, we will address the limitations and considerations associated with this life-saving technology.

The error code P03FC indicates a high signal in the Ignition K control signal circuit. This code is specific to the ignition system and suggests that there is an issue with the voltage level in the control circuit for the ignition system. A high signal typically means that the voltage is above the expected range, which can be caused by several factors, including wiring issues, a faulty ignition control module, or problems with related sensors.

Bài viết liên quan

Pressure switches are essential components found in various systems, including heating, ventilation, and air conditioning (HVAC) units, as well as automotive air conditioning systems. These unassuming devices play a crucial role in ensuring the safe and efficient operation of these systems by monitoring and regulating pressure levels.

Fuses are safety devices used to protect electrical circuits from overloads. They are designed to fail and disconnect power to a component if too much current is drawn, preventing potential damage or hazards.

Automotive HVAC (Heating, Ventilation, and Air Conditioning) systems rely heavily on various temperature sensors to maintain a comfortable cabin environment. These sensors play a crucial role in regulating temperature, airflow, and other climate control functions.