Modular and distributed brake systems represent a significant advancement in vehicle safety technology. These innovative braking solutions offer numerous benefits over traditional centralized braking systems, including improved fault tolerance, enhanced performance, and increased flexibility in vehicle design. By adopting modular and distributed brake systems, the automotive industry is poised to revolutionize the way vehicles handle braking and ensure a safer driving experience for everyone on the road.

Squealing Sounds Brake Symptoms: Causes, Diagnosis, and Repair Solutions

Squealing Sounds Brake Symptoms: Causes, Diagnosis, and Repair Solutions

Introduction

Squealing or squeaking noises coming from the brakes of a vehicle can be an annoying and concerning issue for drivers. These sounds can indicate various underlying problems with the braking system, ranging from minor issues to more serious ones that require immediate attention. Understanding the causes, diagnosis, and repair solutions for squealing brake sounds is crucial for maintaining the safety and proper functioning of a vehicle's braking system.

Main Causes

Squealing sounds in a car can have several potential causes, and it's crucial to identify the root of the problem to address it effectively. Here are some of the most common culprits:

| Cause | Description |

|---|---|

| Worn Brake Pads | As brake pads wear down, the metal backing plate can start rubbing against the brake rotor, causing a high-pitched squealing noise when braking. |

| Lack of Lubrication | Various components in the braking system, such as calipers, pins, and slides, require proper lubrication to function smoothly. Lack of lubrication can cause metal-to-metal contact, resulting in squeaking noises. |

| Glazed Brake Pads | Excessive heat from aggressive braking or riding the brakes can cause the brake pad material to glaze over, reducing friction and leading to squealing. |

| Worn Serpentine Belt | The serpentine belt, which powers various engine accessories, can squeal when it becomes worn, cracked, or misaligned. |

| Failing Alternator Bearings | If the bearings in the alternator are worn, they can cause a high-pitched whining or squealing noise, especially when the engine is under load. |

| Suspension Issues | Worn suspension components, such as bushings, ball joints, or struts, can cause squeaking noises when the vehicle goes over bumps or turns. |

Inspection and Diagnosis

To accurately diagnose the cause of the squealing sound, a thorough inspection is essential. Here are the steps I typically follow:

Listen Carefully

I start by listening carefully to determine the location and timing of the noise.

Is it coming from the front or rear?

Does it occur when braking, accelerating, or turning?

This information helps narrow down the potential causes.

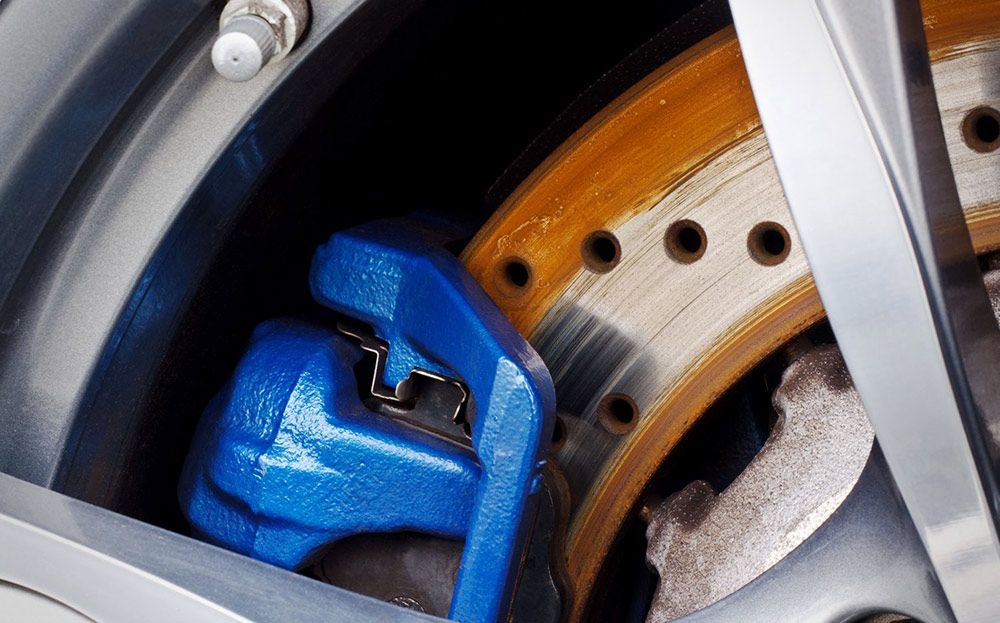

Inspect Brake Components

I visually inspect the brake pads for wear, looking for excessive thinning or the metal backing plate being visible.

I also check the condition of the brake rotors for signs of scoring, grooves, or uneven wear, which can contribute to squealing.

Check the Serpentine Belt

A visual inspection of the serpentine belt can often reveal if it needs replacement due to cracks, fraying, or misalignment.

Examine Suspension Components

I carefully inspect the suspension components, such as bushings, ball joints, and struts, for any signs of wear or damage that could be causing squeaking noises.

Investigate Engine Bay Noises

If the noise seems to be coming from the engine bay, I focus my attention on components like the alternator bearings or other accessory components that could be the source of the squealing.

Repair Instructions

Once the cause of the squealing sound has been identified, the appropriate repair procedures must be followed. Here are some common repair instructions:

Brake Pad Replacement

If the brake pads are worn, I follow the manufacturer's instructions for safely removing the old pads and installing new ones.

Proper bedding-in of the new pads is crucial to ensure optimal performance and prevent future squealing.

The bedding-in process typically involves:

Avoiding heavy braking for the first 100-200 miles

Gradually increasing brake pressure over time

Allowing the pads and rotors to mate properly

Lubrication

In cases where lack of lubrication is the issue, I clean and lubricate the appropriate components, such as caliper pins, slides, and backing plates, using the recommended lubricants.

Proper lubrication can often resolve squeaking noises and extend the life of the components.

Common lubricants used include:

Caliper greases

Brake lubricants

Anti-seize compounds

Brake Rotor Resurfacing or Replacement

If the brake rotors are heavily scored or worn, they may need to be resurfaced or replaced.

I follow the proper procedures for rotor removal and installation, ensuring that the new or resurfaced rotors are properly bedded-in with the brake pads.

Rotor resurfacing involves:

Removing a thin layer of material from the rotor surface

Ensuring even and smooth surfaces for optimal brake pad contact

Serpentine Belt Replacement

When the serpentine belt is the culprit, I refer to the service manual for the correct belt routing and tensioning procedures.

I also inspect and replace any worn pulleys or tensioners as needed to ensure proper belt alignment and prevent future issues.

Proper belt tension is crucial to prevent slipping, squealing, and premature wear.

Alternator Bearing Replacement

If the alternator bearings are failing, this repair typically requires removing the alternator and replacing the bearings or the entire alternator assembly.

Proper installation and alignment are crucial to prevent premature bearing failure.

Specialized tools and procedures may be required for alternator removal and installation.

Suspension Component Replacement

Depending on the specific suspension component that needs attention (bushings, ball joints, struts, etc.), I follow the recommended procedures for safe removal and installation.

Proper torque specifications and alignment are essential for optimal performance and longevity.

Suspension components play a critical role in vehicle handling and safety, so proper installation is paramount.

Preventing Recurrence

While repairs are necessary to address the immediate issue, preventive measures can help avoid future squealing sounds and extend the life of your vehicle's components. Here are some tips I recommend:

| Preventive Measure | Description |

|---|---|

| Regular Brake Inspections | Have your brakes inspected and serviced according to the manufacturer's recommended intervals. This includes checking for wear and proper lubrication, which can prevent squealing and ensure safe braking performance. |

| Driving Habits | Avoid aggressive braking or riding the brakes, as this can cause excessive heat and wear on the brake components, leading to squealing and potential safety hazards. |

| Suspension Maintenance | Follow the recommended intervals for inspecting and replacing suspension components, as worn parts can contribute to squeaking noises, handling issues, and uneven tire wear. |

| Belt and Accessory Inspections | During routine maintenance, have the serpentine belt, alternator, and other accessory components inspected for wear or damage to prevent squealing and potential failures. |

| Proper Lubrication | Use the recommended lubricants and follow the lubrication schedules for all relevant components, such as brakes, suspension, and accessory drive systems. Proper lubrication can significantly extend the life of these components and prevent squeaking noises. |

Cost Considerations

The cost of repairing squealing sounds can vary depending on the cause and the extent of the repair required. Here are some general cost estimates:

| Repair | Cost Range |

|---|---|

| Brake Pad Replacement | $100 - $300 per axle, including parts and labor |

| Brake Rotor Resurfacing or Replacement | $200 - $400 per axle, including parts and labor |

| Serpentine Belt Replacement | $100 - $300, including parts and labor |

| Alternator Bearing or Alternator Replacement | $300 - $800, including parts and labor |

| Suspension Component Replacement | $200 - $1,000 or more, depending on the specific components and labor involved |

It's important to note that these costs are approximate and can vary based on factors such as the make and model of the vehicle, the complexity of the repair, and the labor rates in your area. Additionally, addressing squealing sounds promptly can prevent further damage and potentially more expensive repairs in the long run.

Conclusion

Squealing sounds in a vehicle can be frustrating and may indicate underlying issues that require prompt attention. As a mechanic, I've encountered countless cases where identifying and addressing the root cause of these noises has been crucial for ensuring the safety and longevity of the vehicle.

By following the inspection and diagnosis procedures outlined in this article, and adhering to proper repair and maintenance practices, you can effectively resolve squealing sounds and prevent their recurrence. Remember, regular maintenance and addressing issues promptly can save you from more costly repairs down the line.

If you ever encounter squealing noises in your vehicle, don't hesitate to seek professional assistance. A skilled mechanic can accurately diagnose the problem and provide the necessary repairs to restore your vehicle's smooth and quiet operation.

FAQs

Here is an FAQ section with 10 additional questions related to brake fluid flushing based on the content gaps identified in the article:

What are the signs that my brake fluid needs to be flushed?

Some signs that indicate your brake fluid needs flushing include a spongy or soft brake pedal feel, dark or discolored brake fluid, and warning lights on the dashboard related to the braking system.

How do I know if my brake lines need to be replaced?

During the brake fluid flush process, the mechanic will inspect the brake lines for any leaks, damage or excessive corrosion. If issues are found, they may recommend replacing the affected brake lines.

Can I flush my brake fluid myself or should I have a professional do it?

While it is possible to flush brake fluid yourself if you have mechanical experience, it is generally recommended to have a professional mechanic perform this service to ensure it is done correctly and safely.

How long does a brake fluid flush take?

The time required for a complete brake fluid flush can vary, but typically takes around 1-2 hours for a professional mechanic to perform the service properly.

What happens if I don't replace my brake fluid regularly?

Neglecting to replace your brake fluid regularly can lead to moisture contamination, reduced braking performance, internal corrosion of brake components, and potentially costly repairs or replacements.

Is there a difference between brake fluid types?

Yes, there are different types of brake fluid (DOT 3, DOT 4, DOT 5.1, etc.) with varying boiling points and characteristics. It's crucial to use the type specified by your vehicle's manufacturer.

How do I dispose of old brake fluid properly?

Old brake fluid should be disposed of at a hazardous waste disposal facility or an authorized collection site, as it can be harmful to the environment if not handled correctly.

Can I mix different types of brake fluid?

No, you should never mix different types of brake fluid as it can cause contamination and potentially damage the brake system components. Always use the type specified by the manufacturer.

How often should I have my brake pads and rotors inspected?

It's recommended to have your brake pads and rotors inspected during routine maintenance or whenever you notice any issues with braking performance, such as squeaking, grinding, or pulsation.

Can neglecting brake maintenance lead to accidents?

Yes, neglecting regular brake maintenance, including fluid flushes, can lead to reduced braking performance, component failure, and potentially increase the risk of accidents or collisions due to compromised braking capabilities.

Bình luận (0)

Bài viết đề xuất

Greetings, fellow automotive enthusiasts! Today, we're going to dive deep into a common issue that can plague our beloved vehicles – the dreaded "P036B - Ignition G Control Signal Circuit Low" diagnostic trouble code. As a seasoned mechanic, I've encountered this code numerous times, and I'm here to share my extensive knowledge and real-world experiences with you.

Voltage regulators are indispensable components in modern electronic systems, ensuring stable and reliable voltage levels for optimal device performance and protection against damaging fluctuations. In this comprehensive article, we will explore the types of voltage regulators, their working principles, key components, and wide-ranging applications.

Motorcycles rely heavily on their electrical systems for various functions, including ignition, lighting, instrumentation, and an ever-increasing array of electronic accessories. The alternator is the heart of this electrical system, responsible for generating the necessary power to keep everything running and the battery charged. Without a properly functioning alternator, your motorcycle's electrical components would quickly drain the battery, leaving you stranded.