The P030B code is an OBD-II diagnostic trouble code that stands for "Ignition A Control Signal Circuit Low." This code is triggered when the engine control module (ECM) detects a low voltage in the control circuit of the ignition system. This can lead to various engine performance issues, including misfires, reduced fuel efficiency, and rough idling.

Symptoms Of Low Compression Engine: Signs Your Car Needs Attention

Symptoms Of Low Compression Engine: Signs Your Car Needs Attention

Introduction

An internal combustion engine relies on the compression of the air-fuel mixture within the cylinders to generate power. When the compression is low, it can lead to various issues affecting the engine's performance and efficiency. Low compression can be caused by several factors, including worn piston rings, leaking valves, blown head gaskets, or other internal engine problems. Understanding the symptoms of low compression is crucial for diagnosing and addressing the underlying issue promptly.

The Importance of Engine Compression

Before we dive into the symptoms, let's briefly discuss the significance of engine compression. Compression is a crucial part of the combustion process in your vehicle's engine. It's the force that compresses the air-fuel mixture before ignition, allowing for a powerful and efficient explosion that drives the pistons and ultimately propels your car.

When compression is low, the engine struggles to generate the necessary force, leading to incomplete combustion and a loss of power. This not only affects your vehicle's performance but can also cause further damage if left unaddressed.

Recognizing the Signs

As a mechanic, I've learned to identify the telltale signs of low compression through various indicators. Here are some of the most common symptoms you might experience:

| Symptom | Description |

|---|---|

| Engine Misfiring | If you notice your engine running rough, shaking, or misfiring, it could be a sign of low compression in one or more cylinders. Incomplete combustion due to insufficient compression can cause these irregular firing patterns. |

| Difficulty Starting | When compression is significantly low, your engine may have trouble starting, especially when cold. You might notice that it cranks faster than usual but struggles to turn over and start. |

| Poor Acceleration and Power Loss | Low compression can rob your engine of its ability to generate power efficiently. You may experience sluggish acceleration, a lack of power when climbing hills, or a general decrease in overall performance. |

| Increased Fuel Consumption | With low compression, your engine has to work harder to produce the same amount of power, leading to increased fuel consumption and reduced fuel efficiency. |

| Check Engine Light | In some cases, the engine's computer may detect the misfires caused by low compression and illuminate the check engine light on your dashboard. |

Diagnosing the Root Cause

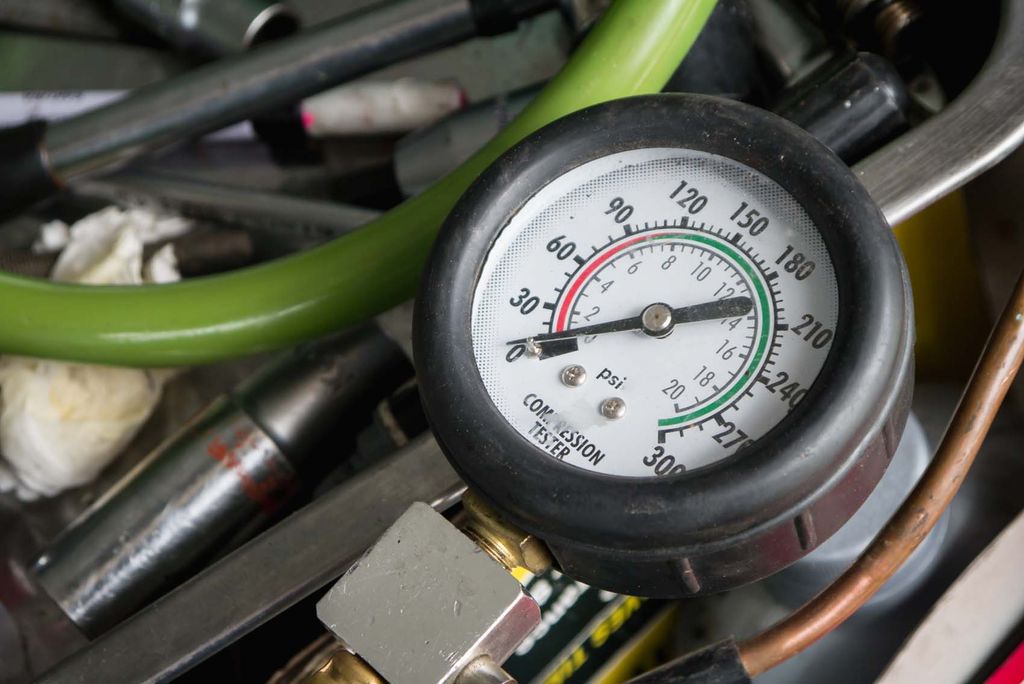

While these symptoms can indicate low compression, it's essential to pinpoint the underlying cause to address the issue effectively. As a mechanic, I rely on a comprehensive compression test to accurately diagnose the problem.

During a compression test, I use a specialized gauge to measure the compression in each cylinder while the engine is cranking. This test provides valuable insights into the condition of the pistons, rings, valves, and head gaskets, allowing me to identify the root cause of the low compression.

Common Culprits of Low Compression

Over the years, I've encountered several common causes of low compression in engines:

Worn Piston Rings or Cylinder Wall Damage

Valve Issues

Head Gasket Failure

Timing Belt/Chain Problems

Piston Damage

Here's a breakdown of each culprit:

| Cause | Description |

|---|---|

| Worn Piston Rings or Cylinder Wall Damage | Piston rings act as a seal between the piston and cylinder wall. If these rings are worn out or the cylinder wall is damaged, compression can leak past the piston, resulting in low compression. |

| Valve Issues | If the intake or exhaust valves do not seal properly due to carbon buildup, dropped valve seats, or other valve train problems, compression can leak past the valves, leading to low compression. |

| Head Gasket Failure | A breach in the head gasket between cylinders or between a cylinder and a coolant passage can allow compression to escape, causing low compression. |

| Timing Belt/Chain Problems | A worn timing belt or chain that is off by a few notches or completely broken can prevent the valves from opening and closing properly, leading to compression loss. |

| Piston Damage | Hot spots on the piston due to overheating or pre-ignition can create holes, allowing compression to escape the cylinder. |

Addressing Low Compression

Once the root cause of low compression has been identified, it's time to take action. The specific repair required will depend on the underlying issue, but here are some common solutions:

Valve Repairs

Piston Ring Replacement

Head Gasket Replacement

Timing Belt/Chain Replacement

Piston/Cylinder Repairs

| Repair | Description |

|---|---|

| Valve Repairs | If the issue lies with the valves, cleaning carbon buildup, replacing valve seals or seats, or repairing valve train components may be necessary. |

| Piston Ring Replacement | If the piston rings are worn, they will need to be replaced, which requires removing the engine and disassembling it. |

| Head Gasket Replacement | A failed head gasket needs to be replaced to restore compression and prevent further damage. |

| Timing Belt/Chain Replacement | A worn or broken timing belt or chain must be replaced to ensure proper valve timing and compression. |

| Piston/Cylinder Repairs | In cases of damaged pistons or cylinders, the components may need machining or replacement, which can be a costly and labor-intensive process. |

Prevention is Key

While low compression issues can be repaired, it's always better to prevent them from occurring in the first place. As a mechanic, I strongly recommend following these preventive measures:

Follow Recommended Service Intervals

Address Overheating Promptly

Use Quality Engine Oil and Replace It Regularly

Avoid Aggressive Driving

The Cost of Repairs

Addressing low compression issues can be costly, depending on the root cause and the extent of the repairs required. As a mechanic, I've seen repair costs ranging from a few hundred dollars for a compression test and minor valve repairs to several thousand dollars for major engine overhauls or replacements.

| Repair | Approximate Cost Range |

|---|---|

| Compression Test Only | $100 - $200 |

| Piston Ring Replacement | $2,000 - $3,500 |

| Head Gasket Replacement | $1,000 - $2,000 |

| Damaged Cylinder Repairs | Up to $8,000 |

It's important to address low compression promptly, as continued driving with low compression can lead to further engine damage and even more expensive repairs down the line.

Conclusion

Low compression in your engine can be a frustrating and potentially costly issue, but understanding the symptoms and underlying causes is the first step toward resolving the problem. As a mechanic, I've seen firsthand the impact of low compression on vehicle performance and the importance of addressing it promptly.

By recognizing the telltale signs, such as engine misfiring, difficulty starting, poor acceleration, and increased fuel consumption, you can take proactive measures to diagnose and repair the issue before it escalates. Regular maintenance, using quality engine oil, and avoiding aggressive driving habits can also help prevent low compression issues from occurring in the first place.

Remember, addressing low compression is not just about restoring your vehicle's performance but also about ensuring its longevity and preventing further damage. If you suspect low compression in your engine, don't hesitate to seek professional assistance from a qualified mechanic. With the right diagnosis and repairs, you can get your vehicle back to peak performance and enjoy a smooth, efficient driving experience.

FAQs

What is the main function of engine compression?

Engine compression is crucial for the combustion process. It compresses the air-fuel mixture before ignition, allowing for a powerful explosion to drive the pistons.

Can low compression cause the check engine light to illuminate?

Yes, in some cases, the engine's computer may detect misfires caused by low compression and trigger the check engine light.

What is a compression test?

A compression test is a diagnostic procedure where a specialized gauge measures the compression in each cylinder while the engine is cranking.

How does worn piston rings lead to low compression?

Worn piston rings fail to seal properly between the piston and cylinder wall, allowing compression to leak past the piston.

Can valve issues contribute to low compression?

Yes, if the intake or exhaust valves do not seal correctly due to carbon buildup or other problems, compression can escape through the valves.

What happens if the head gasket fails?

A failed head gasket can allow compression to escape between cylinders or into the coolant passages, resulting in low compression.

How does a timing belt/chain issue affect compression?

A worn or misaligned timing belt/chain prevents the valves from opening and closing properly, leading to compression loss.

What kind of piston damage can cause low compression?

Hot spots or holes in the piston due to overheating or pre-ignition can allow compression to escape the cylinder.

What are some common repairs for low compression issues?

Common repairs include valve repairs, piston ring replacement, head gasket replacement, timing belt/chain replacement, and piston/cylinder repairs.

Why is it important to address low compression promptly?

Continued driving with low compression can lead to further engine damage and more expensive repairs down the line.

Bình luận (0)

Bài viết đề xuất

Greetings, fellow automotive enthusiasts! Today, we're going to dive deep into a common issue that can plague our beloved vehicles – the dreaded "P036B - Ignition G Control Signal Circuit Low" diagnostic trouble code. As a seasoned mechanic, I've encountered this code numerous times, and I'm here to share my extensive knowledge and real-world experiences with you.

The Anti-lock Braking System (ABS) is a safety technology designed to prevent the wheels of a vehicle from locking up during heavy braking situations. Its primary purpose is to maintain steering control and stability, allowing the driver to maneuver the vehicle safely and avoid potential collisions.

Anti-lock Braking System (ABS) is a critical safety feature in modern vehicles that prevents wheel lockup during hard braking, allowing the driver to maintain steering control and avoid uncontrolled skidding.

Bài viết liên quan

As an experienced automotive mechanic, I've encountered countless drivers who panic when their engine light starts blinking

As an experienced diesel mechanic, I've encountered countless situations where a diesel engine refuses to start, leaving vehicle owners frustrated and stranded.

As an experienced automotive mechanic specializing in diesel engines, I've encountered my fair share of issues with the 7.3L Powerstroke engine. One of the most common and frustrating problems is the failure of the Injector Driver Module (IDM).

As an experienced automotive mechanic, I've encountered my fair share of engine issues, and one of the most challenging problems to diagnose and repair is bent valves. These seemingly small components play a crucial role in the engine's operation, and when they malfunction, it can lead to a cascade of problems that can leave even the most seasoned mechanics scratching their heads.

As an experienced automotive mechanic, I've encountered countless situations where car owners face the frustrating issue of their vehicle not starting. One of the most common culprits is the Acura MDX, a popular luxury

As an experienced automotive mechanic, I've encountered countless cases where a car starts up just fine, but then it starts sputtering and eventually shuts off

Greetings, fellow drivers! As an experienced automotive mechanic, I've encountered countless cases where the dreaded "AC off due to high engine temp" warning light illuminates on the dashboard. It's a frustrating situation, leaving you sweating in discomfort and wondering what went wrong

As an experienced automotive mechanic, I've encountered countless situations where a car refuses to start after overheating. It's a frustrating scenario that can leave drivers stranded and perplexed. In this article, I'll share my insights and expertise on the potential causes, troubleshooting steps, and repair guidance for addressing this common issue.

As an experienced automotive mechanic, I've encountered countless cases where car owners neglected the importance of maintaining proper coolant levels, leading to costly repairs and frustrating breakdowns.

As an experienced automotive mechanic, I've encountered numerous cases where car owners face the frustrating issue of their vehicle refusing to start when the engine is hot. This problem can be perplexing and leave you stranded, especially during hot summer days