The P0045 diagnostic trouble code indicates an issue with the turbocharger or supercharger boost control system, specifically an open circuit in the "A" circuit responsible for regulating boost pressure. This comprehensive guide will explore the causes, symptoms, diagnosis, and repair procedures for this code, ensuring a clear understanding of the problem and its resolution.

What's A Catalytic Converter? Explaining This Emission Control Device

What's A Catalytic Converter? Explaining This Emission Control Device

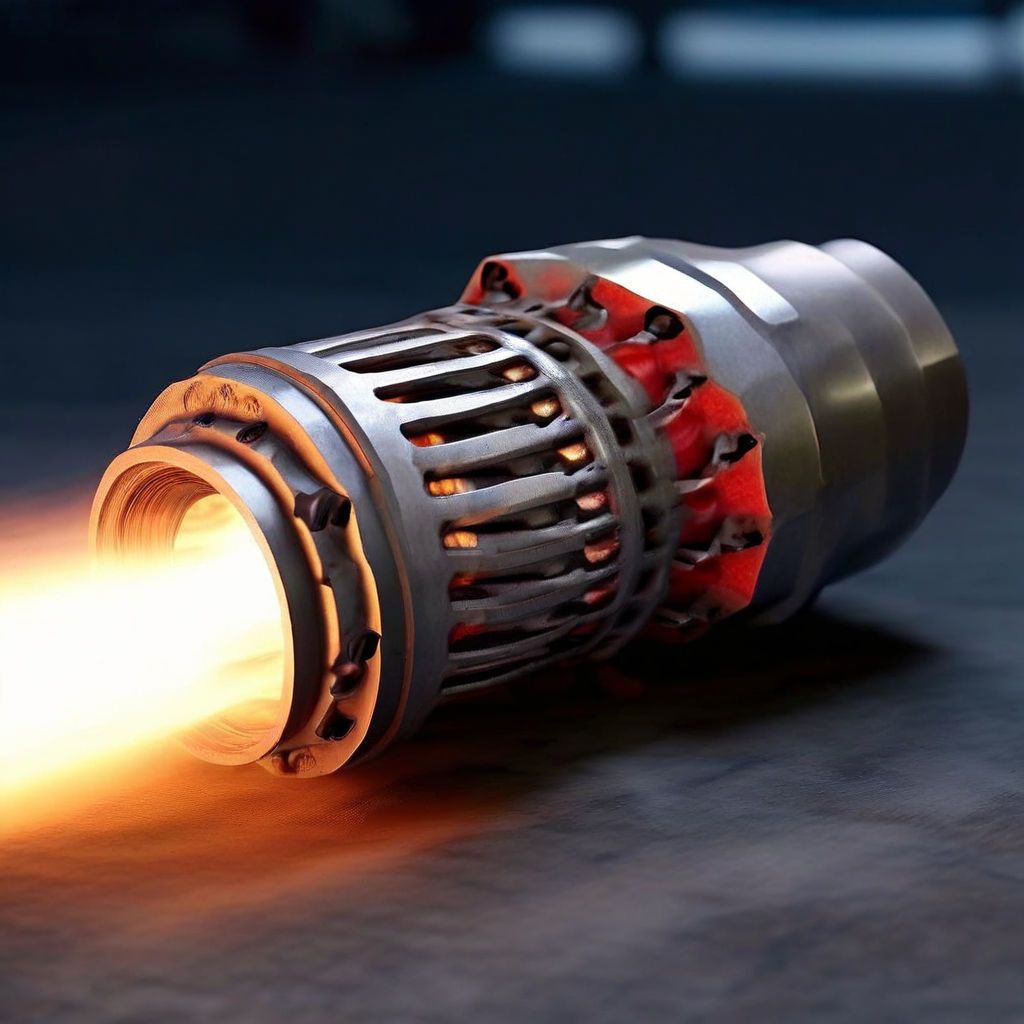

The catalytic converter is an indispensable component of modern vehicles, playing a crucial role in reducing harmful emissions and promoting a cleaner environment. This ingenious device transforms toxic gases produced during the combustion process into less harmful substances before they are released into the atmosphere, making it an unsung hero in the quest for cleaner air.

In this comprehensive article, we will delve into the inner workings of catalytic converters, exploring their construction, types, and the vital role they play in meeting stringent emissions regulations. We will also examine the environmental benefits of these devices, their maintenance requirements, and the ongoing advancements in catalytic converter technology. By understanding the significance of this remarkable invention, we can appreciate the efforts made to mitigate the impact of vehicle emissions on our planet.

I. Introduction

The catalytic converter is an essential component of a vehicle's exhaust system, designed to reduce harmful emissions and promote cleaner air. It plays a crucial role in converting toxic gases produced during the combustion process into less harmful substances before they are released into the atmosphere. The importance of catalytic converters cannot be overstated, as they contribute significantly to improving air quality and protecting the environment.

A. Definition and importance of catalytic converters

Catalytic converters facilitate chemical reactions that transform harmful pollutants into less toxic compounds. By converting carbon monoxide, hydrocarbons, and nitrogen oxides into carbon dioxide, water vapor, and nitrogen, these devices significantly reduce the levels of air pollution caused by vehicle emissions.

B. Overview of their role in reducing vehicle emissions

| Pollutant | Converted to |

|---|---|

| Carbon Monoxide (CO) | Carbon Dioxide (CO2) |

| Hydrocarbons (HC) | Water Vapor (H2O) |

| Nitrogen Oxides (NOx) | Nitrogen (N2) and Oxygen (O2) |

The table above illustrates the primary conversions facilitated by catalytic converters, effectively reducing the levels of harmful pollutants in vehicle emissions.

II. How Catalytic Converters Work

Catalytic converters facilitate two primary chemical reactions: oxidation and reduction. These reactions are made possible by the presence of catalysts, typically precious metals like platinum, palladium, and rhodium, coated on a ceramic or metallic substrate within the converter.

A. Chemical reactions facilitated

1. Oxidation

During the oxidation process, carbon monoxide and unburned hydrocarbons react with oxygen in the presence of catalysts, forming carbon dioxide and water vapor. This reaction effectively reduces the levels of these harmful pollutants in the exhaust gases.

2. Reduction

The reduction process targets nitrogen oxides, which are formed during the combustion of air and fuel. In this reaction, nitrogen oxides are converted into nitrogen and oxygen, both of which are harmless to the environment.

B. Operating temperature range

For optimal performance, catalytic converters require a specific operating temperature range, typically between 400°C (750°F) and 800°C (1,472°F). This is why they are positioned as close to the engine as possible, ensuring they reach the required temperature quickly after the engine starts.

C. Catalysts and their function

The catalysts used in catalytic converters are typically precious metals like platinum, palladium, and rhodium, coated on a ceramic or metallic substrate within the converter. These catalysts act as facilitators, allowing the chemical reactions to occur at lower temperatures without being consumed in the process.

| Catalyst | Function |

|---|---|

| Platinum | Facilitates oxidation of carbon monoxide and hydrocarbons |

| Palladium | Facilitates oxidation of hydrocarbons |

| Rhodium | Facilitates reduction of nitrogen oxides |

The specific combination and distribution of these precious metal catalysts play a crucial role in the overall efficiency of the catalytic converter.

III. Construction and Components

The catalytic converter consists of several key components, each playing a vital role in its overall performance and durability.

A. Substrate

The substrate is the core structure of the catalytic converter, typically a ceramic or metallic honeycomb design, providing a large surface area for the catalytic reactions to occur. The honeycomb structure maximizes the available surface area while minimizing the overall size and weight of the converter.

Ceramic substrates are made of materials like cordierite or mullite, offering excellent thermal resistance and durability.

Metallic substrates, often made of stainless steel or a special alloy, are more resistant to mechanical stress and vibrations.

B. Washcoat

A washcoat, usually made of aluminum oxide or other materials, is applied to the substrate. This coating serves as a carrier for the catalytic materials, ensuring their even distribution and maximizing their effectiveness.

The washcoat plays a crucial role in:

Providing a high surface area for the catalysts to disperse

Stabilizing the catalysts and preventing their agglomeration

Enhancing the catalytic activity and overall efficiency of the converter

C. Precious metal catalysts

The catalysts themselves, such as platinum, palladium, and rhodium, are dispersed within the washcoat. These precious metals facilitate the chemical reactions that convert harmful emissions into less toxic substances.

The specific combination and loading of these catalysts are carefully engineered to optimize the converter's performance for different engine types and emission control requirements.

D. Casing

The outer shell, typically made of stainless steel, protects the internal components and helps maintain the required operating temperature. The casing also ensures that the exhaust gases flow through the catalytic converter efficiently, maximizing the exposure to the catalytic materials.

The casing is designed to withstand high temperatures, corrosion, and mechanical stress, ensuring the longevity and durability of the catalytic converter.

IV. Types of Catalytic Converters

Catalytic converters come in various types, each designed to address specific emission control requirements and engine types.

Two-way catalytic converters

Three-way catalytic converters

Diesel oxidation catalysts (DOCs)

Selective catalytic reduction (SCR) systems

A. Two-way catalytic converters

Two-way catalytic converters were used in gasoline-powered vehicles until the early 1980s. They are designed to oxidize carbon monoxide and unburned hydrocarbons but do not effectively reduce nitrogen oxides.

B. Three-way catalytic converters

Introduced in the 1980s, three-way converters are capable of reducing carbon monoxide, hydrocarbons, and nitrogen oxides simultaneously. They are commonly used in modern gasoline-powered vehicles and are essential for meeting stringent emissions regulations.

| Pollutant | Conversion Process |

|---|---|

| Carbon Monoxide (CO) | Oxidation |

| Hydrocarbons (HC) | Oxidation |

| Nitrogen Oxides (NOx) | Reduction |

Three-way catalytic converters effectively address all three major pollutants produced by gasoline engines, making them a crucial component in modern emission control systems.

C. Diesel oxidation catalysts (DOCs)

Diesel engines require a different type of catalytic converter called a diesel oxidation catalyst (DOC). These converters oxidize carbon monoxide, hydrocarbons, and particulate matter but do not effectively reduce nitrogen oxides.

D. Selective catalytic reduction (SCR) systems

To address nitrogen oxide emissions from diesel engines, selective catalytic reduction (SCR) systems are employed. These systems use a urea-based solution (AdBlue) to convert nitrogen oxides into nitrogen and water.

The SCR system works in conjunction with the DOC, providing a comprehensive solution for reducing both particulate matter and nitrogen oxide emissions from diesel vehicles.

V. Regulations and Emissions Standards

Catalytic converters play a crucial role in helping vehicles comply with emissions regulations and standards set by various governing bodies, such as the Environmental Protection Agency (EPA) in the United States and the California Air Resources Board (CARB).

A. Environmental Protection Agency (EPA) regulations

The Environmental Protection Agency (EPA) in the United States sets strict emissions standards for vehicles, and catalytic converters are essential for manufacturers to comply with these regulations.

The EPA's emissions standards are divided into different tiers, with each tier becoming progressively more stringent over time. Manufacturers must ensure that their vehicles meet the applicable tier standards for the model year and vehicle class.

B. California Air Resources Board (CARB) standards

The California Air Resources Board (CARB) has its own set of stringent emissions standards, often more stringent than the EPA's, and catalytic converters must meet these requirements for vehicles sold in California.

CARB's emissions standards are designed to address the unique air quality challenges faced by the state, and they have played a significant role in driving the development of more advanced emission control technologies.

C. Emissions compliance requirements

Manufacturers must ensure that their vehicles are equipped with catalytic converters that meet the specified emissions standards, which have become increasingly stringent over time. Failure to comply with these regulations can result in significant fines and penalties, as well as potential recalls or sales restrictions.

To demonstrate compliance, vehicles undergo rigorous emissions testing and certification processes, which include evaluating the performance and durability of the catalytic converter under various operating conditions.

VI. Environmental Benefits

The primary environmental benefit of catalytic converters is their ability to significantly reduce air pollution caused by vehicle emissions, contributing to improved air quality and a healthier environment.

A. Reduced air pollution

Catalytic converters play a vital role in mitigating the following forms of air pollution:

Smog and ground-level ozone

Acid rain

Particulate matter

Greenhouse gas emissions

By converting harmful pollutants into less toxic substances, catalytic converters help reduce the formation of smog, ground-level ozone, and acid rain, which can have detrimental effects on human health, vegetation, and ecosystems.

1. Smog and ground-level ozone mitigation

Catalytic converters help mitigate the formation of smog and ground-level ozone by reducing the levels of nitrogen oxides, volatile organic compounds (VOCs), and carbon monoxide in vehicle emissions. These pollutants are key contributors to the formation of smog and ground-level ozone, which can cause respiratory problems and damage vegetation.

2. Ozone layer protection

Catalytic converters contribute to the protection of the ozone layer by reducing nitrogen oxide emissions, which can lead to the depletion of this vital atmospheric layer. The ozone layer shields the Earth from harmful ultraviolet radiation, and its preservation is crucial for human health and the environment.

3. Climate change mitigation

While catalytic converters do not directly target greenhouse gases like carbon dioxide, they contribute to reducing the overall environmental impact of vehicle emissions, which can indirectly mitigate climate change.

By reducing the levels of other pollutants, such as nitrogen oxides and particulate matter, catalytic converters help improve air quality and reduce the overall carbon footprint of the transportation sector.

B. Improved human health

By reducing exposure to harmful pollutants, catalytic converters help protect human health, particularly in urban areas with high traffic density, where air pollution levels can be a significant concern.

Exposure to air pollutants like nitrogen oxides, particulate matter, and ground-level ozone can lead to various respiratory issues, cardiovascular diseases, and other health problems. By reducing the levels of these pollutants, catalytic converters contribute to improving public health and reducing the burden on healthcare systems.

VII. Maintenance and Replacement

Like any other vehicle component, catalytic converters can experience performance issues or failure over time, necessitating maintenance and replacement.

A. Common issues and causes

Several factors can affect the performance of catalytic converters, including:

1. Clogging or contamination

Excessive buildup of particulate matter or exposure to certain contaminants (e.g., lead, silicone) can reduce the converter's efficiency by blocking the flow of exhaust gases or poisoning the catalysts.

Clogging can occur due to:

Excessive oil consumption

Faulty fuel injectors or air filters

Coolant leaks or engine misfiring

Contamination can be caused by:

Leaded gasoline (in older vehicles)

Excessive engine oil consumption

Coolant or fuel additives containing silicone

2. Overheating

Excessive temperatures, often caused by engine problems or exhaust leaks, can damage the catalytic converter's internal components, leading to reduced performance or complete failure.

Overheating can be caused by:

Exhaust system leaks or restrictions

Engine misfiring or rich fuel mixture

Improper converter positioning or insulation

3. Physical damage

Collisions or road debris can cause physical damage to the catalytic converter's casing or internal structure, compromising its ability to function properly.

Physical damage can occur due to:

Road debris or speed bumps

Collisions or accidents

Improper installation or mounting

B. Replacement process and considerations

If a catalytic converter fails or becomes excessively degraded, it must be replaced to maintain emissions compliance and prevent further damage to the exhaust system. Replacement should be performed by a qualified technician, and the new catalytic converter must meet the appropriate emissions standards for the vehicle.

During the replacement process, the following considerations should be taken into account:

Proper diagnosis and identification of the issue

Selection of the correct replacement converter for the vehicle make, model, and engine

Adherence to manufacturer's installation guidelines and torque specifications

Proper disposal or recycling of the old catalytic converter (due to the presence of precious metals)

Regular maintenance and timely replacement of the catalytic converter are essential to ensure optimal performance, emissions compliance, and longevity of the vehicle's exhaust system.

VIII. History and Future Developments

A. Invention and early adoption

The catalytic converter was invented in the 1950s by French engineer Eugene Houdry, who initially developed it for use in oil refineries. However, it wasn't until the 1970s that catalytic converters became widely adopted in the automotive industry, driven by the introduction of stricter emissions regulations in the United States.

B. Technological advancements

Over the years, catalytic converter technology has continued to evolve, with improvements in materials, design, and efficiency. Advancements in substrate design, washcoat composition, and catalyst dispersion have contributed to increased performance and durability.

Some notable technological advancements include:

Improved substrate materials and designs for better thermal management and flow characteristics

Optimized washcoat formulations for enhanced catalyst dispersion and stability

Development of advanced precious metal catalysts with higher activity and selectivity

Integration with other emission control systems, such as particulate filters and selective catalytic reduction (SCR) systems

C. Ongoing research and innovation

As concerns about air pollution and climate change continue to grow, the role of catalytic converters in reducing vehicle emissions will remain crucial. Ongoing research and development efforts aim to further enhance their performance, durability, and cost-effectiveness, contributing to a cleaner and more sustainable transportation sector.

Some areas of ongoing research and innovation include:

Development of alternative catalytic materials and formulations

Improved thermal management and insulation techniques

Integration with advanced engine technologies, such as hybrid and electric powertrains

Optimization for alternative fuels and renewable energy sources

Recycling and recovery of precious metals from spent catalytic converters

Additionally, the automotive industry is exploring complementary emission control technologies, such as gasoline particulate filters and advanced exhaust gas recirculation systems, to further reduce emissions and meet increasingly stringent regulations.

Conclusion

The catalytic converter is a remarkable invention that has played a vital role in mitigating the environmental impact of vehicle emissions. By facilitating chemical reactions that convert harmful pollutants into less toxic substances, these devices have contributed significantly to improving air quality and protecting human health.

As emissions regulations continue to tighten and the demand for sustainable transportation solutions grows, the importance of catalytic converters will only increase. Ongoing advancements in this technology, coupled with the adoption of complementary emission control systems, will be crucial in achieving a cleaner and more environmentally friendly automotive industry.

With continued research, innovation, and a commitment to reducing our environmental footprint, the catalytic converter will remain an essential component in the pursuit of cleaner and more sustainable mobility solutions.

FAQs

What is the purpose of a catalytic converter?

A catalytic converter's purpose is to reduce harmful emissions from a vehicle's exhaust by converting pollutants into less toxic substances. It plays a crucial role in meeting stringent emissions regulations.

How does a catalytic converter work?

It facilitates redox (reduction and oxidation) reactions using catalysts like platinum, palladium, and rhodium to convert pollutants like carbon monoxide, hydrocarbons, and nitrogen oxides into carbon dioxide, water vapor, and nitrogen.

Where is the catalytic converter located in a vehicle?

The catalytic converter is typically located in the exhaust system, between the engine's exhaust manifold and the muffler, close to the engine for optimal operating temperature.

What are the main components of a catalytic converter?

The main components include a stainless steel casing, a ceramic or metallic honeycomb substrate coated with catalysts, a washcoat to disperse the catalysts, and insulation mats.

What causes catalytic converter failure?

Common causes of failure include clogging due to excessive oil consumption or coolant leaks, overheating due to engine misfiring or exhaust leaks, and physical damage from road debris or collisions.

How long does a catalytic converter typically last?

A well-maintained catalytic converter can last for 10 years or 70,000 to 100,000 miles, but its lifespan can be shorter if the vehicle is primarily used for short trips.

Can a catalytic converter be cleaned?

Yes, in some cases, a clogged catalytic converter can be cleaned using chemical cleaners, pressure washing, or soaking methods, potentially extending its lifespan and avoiding replacement.

What are the environmental benefits of catalytic converters?

Catalytic converters significantly reduce air pollution by converting harmful pollutants into less toxic substances, contributing to improved air quality, reduced smog formation, and mitigating climate change.

Are there different types of catalytic converters?

Yes, there are two-way (oxidation) catalytic converters for diesel engines, three-way catalytic converters for gasoline engines, and specialized converters like diesel oxidation catalysts and selective catalytic reduction systems.

What are the future developments in catalytic converter technology?

Ongoing research focuses on improving catalyst formulations, optimizing thermal management, integrating with advanced engine technologies, enabling alternative fuels, and developing cost-effective recycling methods for precious metals.

Bình luận (0)

Bài viết đề xuất

Getting coolant or antifreeze in your eyes can be a severe and potentially sight-threatening emergency. These harsh chemicals can rapidly cause severe burns and permanent vision damage if not treated promptly. This guide will walk you through the crucial steps to take, from immediate first aid to long-term vision care.

The P000D diagnostic trouble code indicates a problem with the variable valve timing system due to a slow camshaft position signal from the "B" sensor on bank 2. Ignoring this code can lead to various engine issues, higher emissions, and reduced fuel economy, potentially causing further damage.

Cars come equipped with mufflers as part of their exhaust systems to reduce noise levels and comply with regulations. However, some car enthusiasts prefer a louder and more aggressive exhaust note for various reasons, such as personal preference or a desire to enhance the driving experience.

Bài viết liên quan

In the world of automotive engineering, the muffler plays a crucial role in ensuring a pleasant and efficient driving experience. This unsung hero of the exhaust system is responsible for reducing the noise and vibrations produced by the engine's combustion process, while also contributing to improved performance and emission control.

Oxygen sensors, commonly known as O2 sensors, are critical components in modern vehicles that play a crucial role in ensuring efficient combustion and emission control.

In the realm of automotive engineering, resonators play a crucial role in shaping the auditory experience and performance of vehicles.

In the relentless pursuit of enhanced performance and efficiency, the automotive industry has embraced a revolutionary technology known as the exhaust turbocharger.

The exhaust system is a critical component of any internal combustion engine vehicle, responsible for expelling harmful gases, reducing emissions, and enhancing overall performance.

The exhaust manifold is a critical component that plays a pivotal role in optimizing your car's performance, emissions control, and overall efficiency. By upgrading this essential part, you can unlock a world of hidden potential, transforming your driving experience and unleashing the true power of your engine.