Brake lines are an integral part of a vehicle's braking system, responsible for transmitting hydraulic pressure from the master cylinder to the wheel cylinders or calipers. This pressure application enables the brakes to slow down or stop the vehicle effectively. Understanding brake lines' functionality, components, maintenance requirements, and replacement procedures is crucial for ensuring optimal braking performance and vehicle safety.

Why Does My Serpentine Belt Squeal After Replacement?

Why Does My Serpentine Belt Squeal After Replacement?

A new serpentine belt can produce a squealing or chirping noise after replacement due to various reasons. This article will explore the common causes and provide practical solutions to diagnose and fix the issue, ensuring smooth and quiet operation.

The serpentine belt is a crucial component that drives multiple accessories in modern vehicles. Proper maintenance and timely replacement are essential for reliable performance. This article covers the causes of noise, diagnostic methods, corrective actions, and maintenance guidelines to maximize the belt's lifespan and prevent future problems.

Understanding the Serpentine Belt System

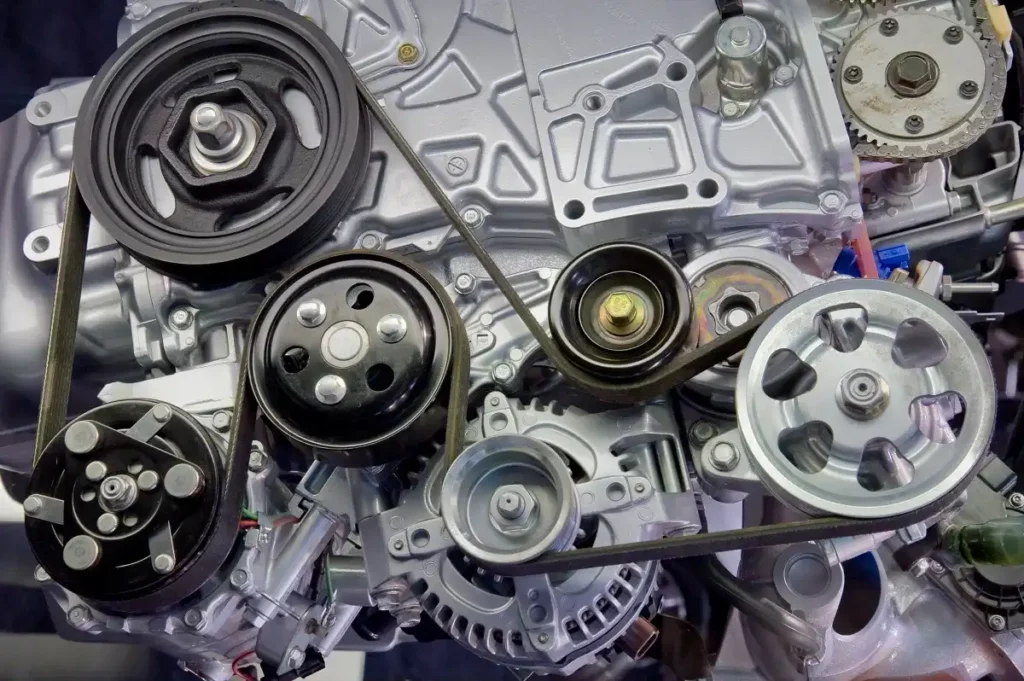

The serpentine belt is a single, continuous belt that wraps around multiple pulleys and accessories in the engine compartment. It transfers rotational power from the crankshaft to components like the alternator, water pump, power steering pump, and air conditioning compressor.

| Component | Function |

|---|---|

| Alternator | Generates electrical power |

| Water Pump | Circulates coolant |

| Power Steering Pump | Provides hydraulic pressure for power steering |

| Air Conditioning Compressor | Compresses refrigerant for the A/C system |

Common serpentine belt issues include cracking, glazing, or material degradation due to heat, age, and environmental factors. Worn or damaged belts can slip, squeal, or break, leading to accessory failure and potential engine damage.

Causes of Noise After Replacement

Pulley or Tensioner Misalignment

If a pulley or the automatic belt tensioner is misaligned, the new belt can rub against the pulley edges, causing a squealing or chirping noise. This misalignment can also lead to premature belt wear.

Worn Pulley or Tensioner Bearings

Even with a new belt, worn pulley bearings or a worn tensioner bearing can allow excessive wobble or vibration, leading to a slapping or chirping noise from the belt hitting the pulleys.

Improper Belt Tension

If the new belt was not tensioned correctly during installation, it can be too loose and slip or squeal against the pulleys, leading to noise and potential accessory failure.

Contamination on Belt or Pulleys

Any oil, coolant, or debris contaminating the new belt or pulley surfaces can cause slippage and squealing until the contaminants are cleaned off.

Defective Belt

In rare cases, a brand new belt may be defective from the factory and produce noise regardless of proper installation.

Diagnosing the Root Cause

A thorough visual inspection is the first step in diagnosing the root cause. Check for:

Pulley and tensioner alignment

Signs of worn pulley or tensioner bearings

Proper belt tension

Contamination on the belt or pulleys

Any other visible damage or issues

Analyzing the noise characteristics can also provide clues about the underlying cause. For example, a high-pitched squeal may indicate belt slippage, while a slapping or chirping noise could suggest misalignment or worn bearings.

In some cases, specialized diagnostic tools like belt tension gauges, pulley alignment tools, bearing inspection tools, or diagnostic scan tools may be required.

Correcting the Issue

| Issue | Corrective Action |

|---|---|

| Pulley or Tensioner Misalignment | Realign pulleys or tensioner |

| Worn Pulley or Tensioner Bearings | Replace worn bearings |

| Improper Belt Tension | Adjust tension or replace tensioner |

| Contamination | Clean contamination, repair leaks |

| Defective Belt | Replace with a high-quality belt |

Proper installation techniques are crucial for ensuring the new serpentine belt operates smoothly and without noise. This includes following the correct routing diagram, maintaining proper tension, and ensuring all pulleys and accessories are properly aligned.

Serpentine Belt Maintenance

Regular inspections and timely replacements are essential for maintaining the serpentine belt system. Follow the manufacturer's recommended intervals, typically every 30,000 to 60,000 miles or as specified in the owner's manual.

In addition to the belt itself, the various accessories and components driven by the belt should also be inspected and serviced as recommended by the manufacturer.

Maintenance Checklist:

Inspect belt for cracks, glazing, or damage

Check belt tension and adjust if necessary

Inspect pulleys and tensioner for wear or damage

Replace belt and components as needed

By following these guidelines, you can keep your vehicle's accessories running reliably and prevent costly breakdowns or repairs.

Conclusion

A squealing or chirping serpentine belt after replacement can be frustrating, but understanding the potential causes and taking the appropriate diagnostic and corrective actions can resolve the issue. Regular maintenance, inspections, and timely replacements are crucial for maximizing the lifespan and performance of the serpentine belt system. By addressing the root cause and following proper installation and maintenance procedures, you can ensure smooth, quiet operation and reliable performance of your vehicle's accessories.

FAQs

What are the most common causes of a serpentine belt squealing after replacement?

The most common causes are pulley or tensioner misalignment, worn pulley or tensioner bearings, improper belt tension, contamination on the belt or pulleys, and a defective belt.

How can you diagnose the root cause of the squealing noise?

A thorough visual inspection and analyzing the noise characteristics can help diagnose the root cause. Specialized diagnostic tools like belt tension gauges or pulley alignment tools may also be required.

What corrective actions can be taken to fix the issue?

Corrective actions include realigning pulleys or tensioner, replacing worn bearings, adjusting belt tension or replacing the tensioner, cleaning contamination and repairing leaks, or replacing the belt with a high-quality one.

Why is proper installation technique important for a new serpentine belt?

Proper installation technique is crucial to ensure the new belt operates smoothly and without noise. This includes following the correct routing, maintaining proper tension, and ensuring all pulleys and accessories are properly aligned.

How often should the serpentine belt be inspected and replaced?

The serpentine belt should be inspected regularly and replaced according to the manufacturer's recommended intervals, typically every 30,000 to 60,000 miles or as specified in the owner's manual.

What other components should be inspected and serviced along with the serpentine belt?

In addition to the belt itself, the various accessories and components driven by the belt, such as the alternator, water pump, power steering pump, and air conditioning compressor, should also be inspected and serviced as recommended by the manufacturer.

What are the consequences of not addressing a squealing serpentine belt?

Not addressing a squealing serpentine belt can lead to premature belt wear, accessory failure, and potential engine damage if the belt breaks or slips off the pulleys.

Can a higher quality serpentine belt help prevent squealing?

In some cases, replacing the belt with a higher quality one from a reputable manufacturer can help prevent squealing, especially if the original belt was defective.

What maintenance practices can help extend the lifespan of a serpentine belt?

Regular inspections, proper belt tension adjustments, keeping pulleys and components clean and free from contamination, and timely replacements can help extend the lifespan of a serpentine belt.

Is it safe to drive with a squealing serpentine belt?

It is generally not recommended to drive with a squealing serpentine belt for an extended period, as it can indicate an underlying issue that may lead to belt failure or accessory problems if not addressed promptly.

Bình luận (0)

Bài viết đề xuất

In the realm of automotive engineering, resonators play a crucial role in shaping the auditory experience and performance of vehicles.

The battery light illuminating during acceleration is a warning sign that should not be overlooked. It typically indicates an issue with the charging system, which is responsible for keeping the battery charged and supplying power to the vehicle's electrical components. Ignoring this symptom can lead to a dead battery and potential damage to other electrical systems.

The "Battery Saver Active" warning light on your vehicle's dashboard indicates a low battery charge condition, prompting the car to enter a power-saving mode. This mode helps conserve the remaining battery power by disabling non-essential electrical components and accessories. Understanding the causes, symptoms, and appropriate actions to take when this warning appears is crucial for maintaining your vehicle's electrical system and avoiding potential breakdowns.