Changing a car battery is a common maintenance task that every vehicle owner will likely face at some point. However, many modern vehicles rely on the battery to maintain various electronic settings and memory functions, such as radio presets, seat positions, and even certain engine control module (ECM) settings

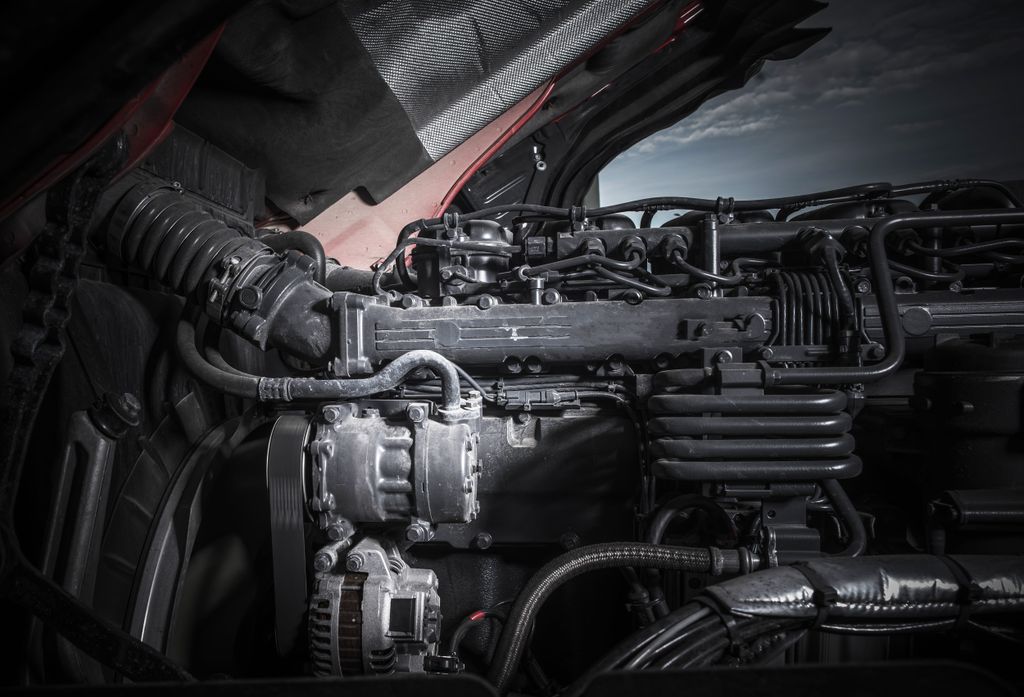

Diesel Engine Won't Start? Troubleshoot Common Causes and Solutions

Diesel Engine Won't Start? Troubleshoot Common Causes and Solutions

Diesel engines are renowned for their durability and reliability, making them a popular choice for various applications, from heavy-duty trucks to construction equipment. However, even the most robust diesel engines can encounter starting issues, leaving you stranded and frustrated. This comprehensive guide aims to equip you with the knowledge and tools necessary to diagnose and resolve diesel engine starting problems effectively.

Introduction

Diesel engines are widely used in various industries due to their fuel efficiency, high torque output, and durability. However, like any mechanical system, they can experience issues that prevent them from starting properly. Understanding the common causes of diesel engine starting problems is crucial for effective troubleshooting and maintenance.

In this article, we will explore the following topics:

Common causes of diesel engine starting problems

A step-by-step troubleshooting guide

Preventive maintenance tips

By addressing these areas, you'll gain a comprehensive understanding of how to identify and resolve diesel engine starting issues, ensuring your engine remains in optimal condition for reliable operation.

Common Causes of Diesel Engine Starting Problems

Identifying the root cause of a diesel engine's failure to start is crucial for implementing the appropriate solution. Several factors can contribute to this issue, ranging from battery problems to fuel system malfunctions. Here are the common causes of diesel engine starting problems:

| Cause | Description |

|---|---|

| Battery Issues | A weak or dead battery can prevent the engine from turning over, leaving it unable to start. A faulty alternator can also cause battery issues by failing to charge the battery properly. |

| Fuel System Problems | Clogged fuel filters, air in fuel lines, faulty fuel pumps, or injector problems can prevent the engine from receiving the necessary fuel for combustion, resulting in starting difficulties. |

| Air Intake Issues | A clogged air filter or obstructions in the air intake system can restrict airflow, preventing the engine from receiving sufficient air for combustion and causing starting problems. |

| Glow Plug Failures | Faulty or worn-out glow plugs can prevent the engine from starting, as they fail to provide the necessary preheating required for combustion, especially in cold weather conditions. |

| Compression Issues | Worn piston rings, leaking valves, or a cracked cylinder head can lead to compression loss, making it difficult or impossible for the engine to start. |

| Electrical System Problems | Faulty wiring, corroded connections, starter motor issues, or solenoid problems can prevent the engine from receiving the required electrical power, resulting in starting difficulties. |

Let's explore each of these causes in more detail:

Battery Issues

The battery plays a vital role in providing the necessary cranking power to start a diesel engine. A weak or dead battery can prevent the engine from turning over, leaving it unable to start.

Common causes of battery issues include:

Age: As batteries age, their ability to hold a charge diminishes, leading to reduced cranking power.

Excessive drain: Leaving electrical accessories on or taking short trips that don't allow the battery to fully recharge can contribute to a weak battery.

Faulty alternator: The alternator is responsible for recharging the battery while the engine is running. If it fails to charge the battery properly, the battery will eventually become depleted, leading to starting difficulties.

Fuel System Problems

Diesel engines rely on a consistent and uninterrupted supply of fuel to operate correctly. Any issues within the fuel system can prevent the engine from receiving the necessary fuel for combustion, resulting in starting problems.

Common fuel system issues include:

Clogged fuel filters: Fuel filters are designed to remove contaminants from the fuel, ensuring a clean supply to the engine. However, over time, these filters can become clogged with debris, restricting fuel flow and causing starting difficulties.

Air in fuel lines: Air pockets in the fuel lines can disrupt the flow of fuel to the injectors, preventing proper combustion. This issue may arise due to improper maintenance, a leak in the fuel system, or running out of fuel.

Faulty fuel pump: The fuel pump is responsible for delivering fuel from the tank to the injectors at the correct pressure. If the pump fails or becomes worn, it may not provide sufficient fuel pressure, leading to starting issues.

Injector problems: Injectors are responsible for atomizing and injecting the fuel into the combustion chamber. If one or more injectors are clogged or malfunctioning, the engine may not receive the necessary fuel for combustion, resulting in starting difficulties.

Air Intake Issues

Diesel engines require a steady supply of air to facilitate combustion. Any restrictions or obstructions in the air intake system can prevent the engine from receiving the necessary air, leading to starting problems.

Common air intake issues include:

Clogged air filter: The air filter is designed to remove contaminants from the incoming air, ensuring a clean supply to the engine. However, over time, the filter can become clogged with dirt, dust, or debris, restricting airflow and causing starting difficulties.

Obstructions in the air intake system: A collapsed or damaged air intake hose or a blocked air intake duct can prevent the engine from receiving sufficient air, leading to starting issues.

Glow Plug Failures

Glow plugs are essential components in diesel engines, particularly in cold weather conditions. Their primary function is to preheat the combustion chamber, facilitating the ignition of the fuel-air mixture during the starting process.

Common glow plug issues include:

Faulty glow plugs: Faulty glow plugs can prevent the engine from starting, as they fail to provide the necessary preheating required for combustion.

Worn-out glow plugs: Over time, glow plugs can degrade due to repeated heating and cooling cycles, reducing their effectiveness in preheating the combustion chamber.

Compression Issues

Proper compression is crucial for diesel engine operation. Compression issues can arise due to various factors, such as worn piston rings, leaking valves, or a cracked cylinder head, all of which can lead to compression loss and starting difficulties.

Common compression issues include:

Worn piston rings: Worn piston rings can cause a loss of compression by allowing air and combustion gases to escape from the combustion chamber, preventing the engine from building up the necessary pressure for ignition.

Leaking valves: Valves are responsible for controlling the flow of air and exhaust gases in and out of the combustion chamber. If the valves are not sealing properly, compression can be lost, making it difficult for the engine to start.

Cracked cylinder head: The cylinder head plays a crucial role in sealing the combustion chamber and maintaining compression. If the cylinder head is cracked or damaged, compression can be lost, leading to starting problems.

Electrical System Problems

Diesel engines rely on a robust electrical system to provide the necessary power for starting and operation. Any issues within the electrical system can prevent the engine from receiving the required electrical power, resulting in starting difficulties.

Common electrical system issues include:

Faulty wiring or corroded connections: Faulty wiring or corroded connections can disrupt the flow of electrical current, preventing the starter motor from receiving the necessary power to crank the engine.

Malfunctioning starter motor: The starter motor is responsible for cranking the engine during the starting process. If the starter motor fails or becomes worn, it may not have the power to turn over the engine, preventing it from starting.

Solenoid problems: The solenoid is an electrical component that engages the starter motor when the ignition key is turned. If the solenoid fails or becomes stuck, it can prevent the starter motor from engaging, making it impossible for the engine to start.

Step-by-Step Troubleshooting Guide

Once you have identified the potential causes of your diesel engine's starting issues, it's time to implement a systematic troubleshooting approach. This step-by-step guide will help you diagnose and resolve the problem effectively.

Check the Battery

The first step in troubleshooting a diesel engine that won't start is to check the battery's condition. Use a voltmeter to measure the battery's voltage, ensuring it meets the manufacturer's recommended specifications. A fully charged battery should read around 12.6 volts or higher.

Inspect the battery terminals for any signs of corrosion or loose connections. Clean the terminals if necessary and ensure they are securely fastened. If the battery is weak or dead, charge or replace it as needed.

Inspect the Fuel System

Next, inspect the fuel system for any potential issues. Check the fuel level in the tank and ensure there are no leaks or obstructions in the fuel lines. Replace the fuel filters if they are clogged or haven't been changed in a while.

If you suspect air in the fuel lines, bleed the air from the system following the manufacturer's recommended procedure. This process involves running the fuel pump or cranking the engine to purge any air pockets from the fuel lines.

If the fuel pump or injectors are suspected to be faulty, further diagnosis or replacement may be necessary.

Check the Air Intake System

Ensure the air intake system is free from obstructions or clogs. Inspect the air filter and replace it if it appears dirty or clogged. Check the air intake hoses and ducts for any signs of damage or blockages, and rectify any issues found.

A restricted air intake can prevent the engine from receiving the necessary air for combustion, leading to starting difficulties.

Test the Glow Plugs

Glow plugs play a crucial role in preheating the combustion chamber, especially in cold weather conditions. Use a voltmeter or glow plug tester to check the functionality of each glow plug. Replace any faulty or worn-out glow plugs as needed.

Proper glow plug operation is essential for ensuring the fuel-air mixture ignites during the starting process.

Perform a Compression Test

If the engine still won't start after addressing the above issues, perform a compression test to check for compression loss. Low compression can indicate worn piston rings, leaking valves, or other internal engine problems that may require further inspection or repairs.

Follow the manufacturer's recommended procedure for performing a compression test, and compare the results to the specified values for your engine model.

Inspect the Electrical System

Check the starter motor, solenoid, and wiring connections for any issues. Ensure there are no loose or corroded connections, and replace any faulty components as necessary.

Use a voltmeter to check the voltage at the starter motor during the cranking process. If the voltage is low, it may indicate a wiring or battery issue that needs to be addressed.

Analyze Diagnostic Trouble Codes

If your diesel engine is equipped with an on-board diagnostic system, retrieve and analyze any diagnostic trouble codes (DTCs) related to the starting issue. These codes can provide valuable insights into the root cause of the problem and guide you toward the appropriate repair or replacement.

Consult the manufacturer's service manual or a professional mechanic for assistance in interpreting and addressing the diagnostic trouble codes.

Preventive Maintenance Tips

While troubleshooting is essential when faced with starting issues, preventive maintenance can help minimize the risk of such problems occurring in the first place. Here are some tips to keep your diesel engine in top condition:

| Maintenance Task | Description |

|---|---|

| Replace Fuel Filters Regularly | Fuel filters play a crucial role in keeping the fuel system clean and free from contaminants. Follow the manufacturer's recommended intervals for replacing the fuel filters to ensure optimal fuel flow and prevent clogging. |

| Perform Routine Oil Changes | Regular oil changes are essential for maintaining the health of your diesel engine. Fresh, high-quality engine oil helps lubricate moving parts, reduce wear, and prevent sludge buildup, which can lead to various engine issues, including starting problems. |

| Maintain Battery and Clean Terminals | Regularly inspect your battery's condition and clean the terminals to ensure proper electrical connections. Corrosion or loose connections can prevent the battery from providing the necessary cranking power, leading to starting difficulties. |

| Inspect and Replace Worn-Out Glow Plugs | Glow plugs have a limited lifespan and can wear out over time. Inspect and replace worn-out glow plugs during scheduled maintenance intervals to ensure proper preheating of the combustion chamber, especially in colder weather conditions. |

| Check and Replace Air Filters | Clogged air filters can restrict airflow and prevent the engine from receiving the necessary air for combustion. Check and replace air filters according to the manufacturer's recommendations to maintain optimal air intake and engine performance. |

| Adhere to Manufacturer's Maintenance Schedule | Follow the manufacturer's recommended maintenance schedule for your specific diesel engine model. Regular maintenance, including inspections, adjustments, and replacements of various components, can help prevent starting issues and ensure reliable engine operation. |

By following these preventive maintenance tips, you can significantly reduce the likelihood of encountering diesel engine starting problems and extend the lifespan of your engine.

Conclusion

Troubleshooting a diesel engine that won't start can be a challenging task, but with the right knowledge and systematic approach, you can identify and resolve the issue effectively. By understanding the common causes of starting problems, following the step-by-step troubleshooting guide, and implementing preventive maintenance practices, you can keep your diesel engine running smoothly and avoid frustrating breakdowns.

Remember, regular maintenance and prompt attention to any issues are key to ensuring the longevity and reliable performance of your diesel engine. If you encounter persistent starting issues or require professional assistance, don't hesitate to consult with a qualified diesel mechanic for further diagnosis and repairs.

FAQs

What are the signs of a faulty glow plug system?

Difficulty starting the engine in cold weather and excessive white smoke from the exhaust are common indicators of a faulty glow plug system. The glow plugs may need replacement if they are not preheating the combustion chamber effectively.

How can I check for air leaks in the intake system?

With the engine running, spray a water-based solvent around the intake system components. If the engine RPM changes, it indicates an air leak that needs to be sealed.

What is the purpose of bleeding the fuel system?

Bleeding the fuel system helps remove any trapped air pockets, ensuring a consistent fuel flow to the injectors. This process is crucial after fuel filter changes or when the fuel tank has run dry.

How often should I replace the fuel filters?

Most manufacturers recommend replacing the fuel filters every 20,000 to 30,000 miles or once a year, whichever comes first. Consult your owner's manual for specific intervals.

Can a weak battery cause starting issues?

Yes, a weak or discharged battery can prevent the starter motor from cranking the engine with sufficient speed, leading to starting difficulties. Battery condition should be checked regularly.

What are the signs of a failing starter motor?

Grinding or whirring noises when trying to start the engine, or the engine not cranking at all, can indicate a failing starter motor that needs replacement.

How can I check for fuel contamination?

Visually inspect the fuel for any water, sediment, or discoloration. You can also have a fuel sample analyzed by a professional lab to determine if contamination is present.

What is the purpose of a compression test?

A compression test helps identify any compression issues within the cylinders, such as worn piston rings, leaking valves, or a cracked cylinder head, which can prevent the engine from starting.

Can low coolant levels cause starting problems?

Yes, low coolant levels can lead to overheating, which can cause various engine components to expand and potentially prevent the engine from starting or running properly.

What should I do if my diesel engine is still not starting after troubleshooting?

If you have exhausted all troubleshooting steps and the engine still won't start, it's advisable to seek professional assistance from a qualified diesel mechanic for further diagnosis and repairs.

Bình luận (0)

Bài viết đề xuất

Tire patching is a way to repair tires that have been punctured or have holes in the tread area. It is a temporary fix to allow the tire to be usable until it can be replaced. There are two main methods of patching a tire: plugging or patching.

The 2024 Jeep Gladiator has redefined the mid-size truck segment with its remarkable towing capabilities, surpassing many of its competitors. This comprehensive article delves deep into the Gladiator's towing capacity, exploring the factors that contribute to its impressive performance, real-world experiences, and how it stacks up against other vehicles in its class.

The GMC Hummer EV is a revolutionary all-electric supertruck that promises incredible performance both on and off-road. However, one crucial aspect that often determines a truck's capability is its towing capacity.

Bài viết liên quan

The 7.3L Powerstroke diesel engine, found in Ford Super Duty trucks from 1994 to 2003, is renowned for its durability and longevity. However, proper maintenance, particularly regular oil changes, is crucial to ensure its continued optimal performance.

Catalytic converters play a crucial role in reducing harmful emissions from vehicles, including diesel pickups. As environmental regulations become more stringent, understanding the necessity and functionality of these emission control devices is essential for diesel pickup owners and enthusiasts.

When it comes to moving and relocation, understanding the fuel requirements of your rental truck is crucial. U-Haul, one of the leading moving truck rental companies, has made a significant shift by transitioning its entire fleet to run on regular unleaded gasoline instead of diesel fuel.

Removing water from diesel fuel is crucial to prevent costly engine damage and maintain optimal performance. This comprehensive guide explores the best additives to remove water from diesel fuel, their top picks, and provides valuable insights for car enthusiasts and diesel vehicle owners.

Cummins Inc., a global leader in power solutions, has established itself as a manufacturing powerhouse in the engine production industry. With a rich heritage spanning over a century, the company has consistently pushed the boundaries of innovation, quality, and sustainability, solidifying its position as a premier engine manufacturer for diverse industries worldwide.

Diesel engines are a unique breed of internal combustion engines that operate on a fundamentally different principle than their gasoline counterparts. Unlike gasoline engines, which rely on spark plugs to ignite the fuel-air mixture, diesel engines utilize a process called compression ignition, eliminating the need for spark plugs altogether.

The Ford F350 Super Duty diesel 4x4 is a powerhouse on wheels, designed to tackle the toughest jobs and conquer the most challenging terrains. However, to truly unleash its full potential, it's essential to equip this heavy-duty workhorse with the right suspension components, specifically shocks that can handle its immense weight and demanding usage.

The use of red diesel, a rebated fuel intended for off-road vehicles and machinery, has long been a tempting option for those seeking cost savings. However, the practice of removing the distinctive red dye from this fuel to use it illegally on public roads is fraught with legal risks, technical challenges, and environmental concerns.

Diesel Exhaust Fluid (DEF) is a non-toxic, aqueous solution composed of 32.5% automotive-grade urea and 67.5% deionized water. It plays a crucial role in the Selective Catalytic Reduction (SCR) system, which is an emissions control technology used in modern diesel engines to reduce harmful nitrogen oxide (NOx) emissions.