<p><h1 id="what-should-ac-pressure-be-with-engine-off-an-expert-s-perspective">What Should AC Pressure Be With Engine Off? An Expert's Perspective</h1></p> <p><h2 id="introduction">Introduction</h2></p> <p>As an automotive mechanic with years of experience, I've encountered countless situations where car owners are puzzled by their vehicle's air conditioning (AC) system. One of the most common questions I receive is, "What should the AC pressure be with the engine off?" This query often arises when drivers notice their AC isn't cooling as effectively as it should, or they suspect a potential issue with the system.</p> <p>In this article, I'll delve into the intricacies of AC pressure readings, the factors that influence them, and the steps you can take to diagnose and address any underlying problems. Buckle up, as we embark on a journey to demystify this crucial aspect of automotive air conditioning.</p> <h2 id="understanding-ac-pressure-readings">Understanding AC Pressure Readings</h2> <p>Before we dive into the specifics of AC pressure with the engine off, it's essential to grasp the fundamental principles of how an automotive air conditioning system operates. The AC system is a closed-loop circuit that circulates refrigerant, a specialized liquid/gas mixture responsible for absorbing heat from the cabin and expelling it outside the vehicle.</p> <table> <thead> <tr> <th>Component</th> <th>Function</th> </tr> </thead> <tbody> <tr> <td>Compressor</td> <td>Compresses the refrigerant gas, increasing its pressure and temperature</td> </tr> <tr> <td>Condenser</td> <td>Dissipates heat from the high-pressure, high-temperature refrigerant gas, causing it to condense into a liquid</td> </tr> <tr> <td>Expansion Valve/Orifice Tube</td> <td>Regulates the flow of refrigerant from the high-pressure side to the low-pressure side</td> </tr> <tr> <td>Evaporator</td> <td>Absorbs heat from the cabin air, causing the liquid refrigerant to evaporate and cool the air</td> </tr> </tbody> </table> <p>The pressure within this closed-loop system is a critical indicator of its overall health and performance. When the engine is running, the AC compressor, driven by the engine, compresses the refrigerant gas, increasing its pressure and temperature. This high-pressure, high-temperature gas then flows through the condenser, where it dissipates heat and condenses back into a liquid state.</p> <p>However, when the engine is off, the compressor is not actively compressing the refrigerant, and the system should reach a state of equilibrium, where the pressures on both the high and low sides of the system equalize.</p> <h2 id="ideal-ac-pressure-with-engine-off">Ideal AC Pressure with Engine Off</h2> <p>In an ideally functioning AC system with no leaks or component failures, the static pressures on both the high and low sides should equalize and match the ambient temperature pressure. This pressure is typically measured in pounds per square inch (PSI) and can be easily determined using a temperature-pressure chart or an AC manifold gauge set.</p> <p>For example, if the ambient temperature is 75°F (24°C), the static pressure on both sides of the AC system should be around 55-60 PSI when the engine is off. This equilibrium pressure is crucial because it indicates that the system is holding the correct amount of refrigerant and that there are no significant leaks or blockages.</p> <table> <thead> <tr> <th>Ambient Temperature</th> <th>Expected Static Pressure (PSI)</th> </tr> </thead> <tbody> <tr> <td>65°F (18°C)</td> <td>40-45 PSI</td> </tr> <tr> <td>75°F (24°C)</td> <td>55-60 PSI</td> </tr> <tr> <td>85°F (29°C)</td> <td>70-75 PSI</td> </tr> <tr> <td>95°F (35°C)</td> <td>90-95 PSI</td> </tr> </tbody> </table> <h2 id="common-causes-of-improper-ac-pressures">Common Causes of Improper AC Pressures</h2> <p>While an ideal AC system should exhibit balanced pressures when the engine is off, several factors can disrupt this equilibrium, leading to improper pressure readings. Here are some of the most common culprits:</p> <h3 id="refrigerant-leaks">Refrigerant Leaks</h3> <p>The most prevalent issue causing improper AC pressures is a refrigerant leak within the system. Even small leaks over time can result in low refrigerant levels, which can cause the pressures on both sides to drop below the expected values. Refrigerant leaks can occur due to various reasons, such as:</p> <ul> <li>Worn-out seals or gaskets</li> <li>Damaged hoses or fittings</li> <li>Corrosion in the system components</li> <li>Punctures or cracks in the condenser or evaporator</li> </ul> <h3 id="compressor-failure">Compressor Failure</h3> <p>The compressor is the heart of the AC system, responsible for circulating and compressing the refrigerant. If the compressor fails or becomes faulty, it can disrupt the refrigerant flow and cause uneven or abnormal pressure readings, even with the engine off.</p> <p>Common signs of compressor failure include:</p> <ul> <li>Loud noises or grinding sounds from the compressor</li> <li>Excessive vibration or shaking</li> <li>Leaking refrigerant or oil around the compressor</li> </ul> <h3 id="clogged-expansion-valve-or-orifice-tube">Clogged Expansion Valve or Orifice Tube</h3> <p>The expansion valve or orifice tube is a critical component that regulates the flow of refrigerant from the high-pressure side to the low-pressure side of the system. If these components become clogged or obstructed, it can lead to improper pressure readings and inefficient cooling.</p> <p>Causes of a clogged expansion valve or orifice tube include:</p> <ul> <li>Contaminants or debris in the refrigerant</li> <li>Moisture or corrosion buildup</li> <li>Improper installation or maintenance</li> </ul> <h3 id="other-component-failures">Other Component Failures</h3> <p>While less common, failures in other AC system components, such as the condenser, evaporator, or receiver/drier, can also contribute to improper pressure readings and overall system performance issues.</p> <ul> <li>Condenser issues: Blocked or restricted airflow, leaks, or damage</li> <li>Evaporator issues: Clogged or frozen, leaks, or damage</li> <li>Receiver/drier issues: Clogged or saturated desiccant, leaks, or damage</li> </ul> <h2 id="diagnosing-and-repairing-ac-pressure-issues">Diagnosing and Repairing AC Pressure Issues</h2> <p>If you suspect an issue with your vehicle's AC system due to improper pressure readings with the engine off, it's crucial to have a professional technician diagnose and repair the problem. Here's a general overview of the diagnostic and repair process:</p> <h3 id="connecting-the-ac-manifold-gauge-set">Connecting the AC Manifold Gauge Set</h3> <p>The first step in diagnosing AC pressure issues is to connect an AC manifold gauge set to the service ports on the high and low sides of the system. This specialized tool allows you to monitor the pressures on both sides and identify any discrepancies or abnormalities.</p> <table> <thead> <tr> <th>Gauge Set Component</th> <th>Function</th> </tr> </thead> <tbody> <tr> <td>Low-side gauge</td> <td>Measures the pressure on the low-pressure side of the system</td> </tr> <tr> <td>High-side gauge</td> <td>Measures the pressure on the high-pressure side of the system</td> </tr> <tr> <td>Manifold</td> <td>Connects the gauges to the service ports</td> </tr> <tr> <td>Hoses</td> <td>Allow refrigerant flow between the system and the gauge set</td> </tr> </tbody> </table> <h3 id="checking-static-pressures">Checking Static Pressures</h3> <p>With the engine off and the AC system at rest, the technician will observe the static pressures on both the high and low sides. If the pressures are low or uneven, it indicates a leak or other system fault that needs further investigation.</p> <h3 id="leak-detection-and-repair">Leak Detection and Repair</h3> <p>If a leak is suspected, the technician will use specialized tools, such as UV dye or electronic leak detectors, to pinpoint the source of the leak. Once identified, the faulty component(s) will be repaired or replaced, and the system will be evacuated and recharged with the correct amount of refrigerant and lubricant.</p> <ul> <li>UV dye: A fluorescent dye is injected into the system, and a UV light is used to locate the leak</li> <li>Electronic leak detector: A sensitive device that can detect the presence of refrigerant gas</li> </ul> <h3 id="component-replacement">Component Replacement</h3> <p>In cases where a major component, such as the compressor or expansion valve, has failed, replacement of the faulty part is typically required. This process involves evacuating the system, replacing the component, and then recharging the system with the appropriate refrigerant and lubricant levels.</p> <h3 id="system-recharge-and-verification">System Recharge and Verification</h3> <p>After repairs or component replacements, the AC system will be recharged with the correct amount of refrigerant and lubricant. The technician will then verify the pressures with the engine off to ensure the system is operating within the expected parameters.</p> <h2 id="preventing-future-ac-pressure-issues">Preventing Future AC Pressure Issues</h2> <p>While AC pressure issues can be frustrating and costly to repair, there are several proactive measures you can take to prevent or minimize the likelihood of future problems:</p> <h3 id="regular-maintenance">Regular Maintenance</h3> <p>Scheduling regular AC system maintenance is crucial for identifying and addressing potential issues before they escalate. During these services, a technician will:</p> <ul> <li>Check for leaks</li> <li>Inspect system components</li> <li>Recharge the refrigerant if necessary</li> <li>Clean or replace air filters</li> <li>Check for proper airflow and cooling performance</li> </ul> <h3 id="use-the-ac-system-frequently">Use the AC System Frequently</h3> <p>Using your vehicle's AC system regularly, even during cooler months, can help keep the components lubricated and prevent seals from drying out and cracking, which can lead to leaks. It's recommended to run the AC for at least 10-15 minutes every few weeks, even in cooler weather.</p> <h3 id="avoid-diy-recharging-with-stop-leak-additives">Avoid DIY Recharging with Stop-Leak Additives</h3> <p>While it may be tempting to attempt a DIY recharge with stop-leak additives, these products can often cause more harm than good. They can clog system components and make future repairs more difficult and expensive.</p> <h3 id="address-issues-promptly">Address Issues Promptly</h3> <p>If you notice any signs of AC system issues, such as reduced cooling performance, unusual noises, or visible leaks, it's essential to have the system inspected and repaired promptly. Ignoring these issues can lead to further damage and more costly repairs down the line.</p> <h2 id="cost-considerations">Cost Considerations</h2> <p>When it comes to AC pressure issues and repairs, it's essential to consider the associated costs. Professional AC diagnosis typically ranges from $100 to $200, while a full recharge service can cost between $150 and $300 on average.</p> <p>However, if major component replacements are required, such as a new compressor, the costs can escalate significantly, ranging from $500 to $1,000 or more in parts and labor.</p> <table> <thead> <tr> <th>Repair/Service</th> <th>Average Cost Range</th> </tr> </thead> <tbody> <tr> <td>AC Diagnosis</td> <td>$100 - $200</td> </tr> <tr> <td>Recharge Service</td> <td>$150 - $300</td> </tr> <tr> <td>Compressor Replacement</td> <td>$500 - $1,000+</td> </tr> <tr> <td>Condenser Replacement</td> <td>$300 - $800</td> </tr> <tr> <td>Evaporator Replacement</td> <td>$400 - $1,000</td> </tr> </tbody> </table> <p>It's important to remember that maintaining your vehicle's AC system proactively is far less expensive than dealing with major repairs down the line. Regular maintenance and addressing issues promptly can save you significant money and hassle in the long run.</p> <h2 id="conclusion">Conclusion</h2> <p>Understanding AC pressure readings, particularly with the engine off, is crucial for diagnosing and addressing issues with your vehicle's air conditioning system. By following the guidelines outlined in this article and working with a qualified technician, you can ensure that your AC system operates at optimal efficiency, providing you with a comfortable driving experience.</p> <p>Remember, proper maintenance and addressing issues promptly are key to preventing costly repairs and ensuring the longevity of your vehicle's AC system. Don't hesitate to seek professional assistance when dealing with AC pressure issues, as attempting DIY repairs without the necessary knowledge and tools can often lead to further complications.</p> <p>Stay cool, stay informed, and enjoy a refreshing driving experience with a well-maintained and properly functioning air conditioning system.</p> <h2 id="faqs">FAQs</h2> <h3 id="-what-should-i-do-if-the-ac-fan-is-not-running-"><strong>What should I do if the AC fan is not running?</strong></h3> <p>First, try resetting the furnace circuit breaker. If the fan still doesn't start, you should call a professional HVAC technician for further assistance.</p> <h3 id="-how-do-i-discharge-the-stored-energy-in-an-old-capacitor-"><strong>How do I discharge the stored energy in an old capacitor?</strong></h3> <p>Use a non-conductive tool to short the terminals of the old capacitor before disconnecting any wires. This will safely discharge any residual energy.</p> <h3 id="-how-often-should-i-replace-the-ac-contactor-"><strong>How often should I replace the AC contactor?</strong></h3> <p>It's recommended to replace the AC contactor every five years, even if it appears to be working properly.</p> <h3 id="-what-are-the-signs-that-the-ac-compressor-is-not-working-"><strong>What are the signs that the AC compressor is not working?</strong></h3> <p>If the compressor doesn't run or make any noise when the AC is turned on, it's likely that the compressor has failed and needs to be replaced.</p> <h3 id="-how-can-i-test-if-my-ac-repairs-were-successful-"><strong>How can I test if my AC repairs were successful?</strong></h3> <p>After completing the repairs, reinstall the access panel, turn on the power, and set the thermostat to a lower temperature. The compressor and condenser fan should start running.</p> <h3 id="-what-should-i-do-if-the-condenser-fan-is-not-spinning-"><strong>What should I do if the condenser fan is not spinning?</strong></h3> <p>If the compressor starts but the fan doesn't spin, the fan motor may be faulty and need to be replaced.</p> <h3 id="-how-do-i-clean-the-ac-coils-"><strong>How do I clean the AC coils?</strong></h3> <p>Use a soft brush or vacuum attachment to gently remove any dirt or debris buildup on the evaporator and condenser coils.</p> <h3 id="-what-are-the-signs-that-the-ac-refrigerant-is-low-"><strong>What are the signs that the AC refrigerant is low?</strong></h3> <p>Low refrigerant levels can cause the AC to struggle to cool the house effectively or cause the compressor to run continuously without cooling.</p> <h3 id="-how-often-should-i-change-the-ac-air-filters-"><strong>How often should I change the AC air filters?</strong></h3> <p>Air filters should be changed or cleaned every 1-3 months, depending on usage and the manufacturer's recommendations.</p> <h3 id="-what-should-i-do-if-the-ac-is-not-turning-on-at-all-"><strong>What should I do if the AC is not turning on at all?</strong></h3> <p>Check the thermostat settings, circuit breakers, and outdoor disconnect to ensure power is reaching the AC unit. If the issue persists, contact a professional for further diagnosis.</p>

How To Get Air Out Of Brake Lines Without Bleeding?

How To Get Air Out Of Brake Lines Without Bleeding?

Removing air from brake lines is crucial for maintaining proper brake function and safety. When air enters the brake system, it can cause a spongy or soft brake pedal feel, reducing braking performance. While the traditional method of bleeding brakes requires a helper, there are several DIY techniques that allow you to get air out of brake lines without bleeding. In this article, we will explore the causes of air in brake lines, prepare the brake system for air removal, and guide you through the gravity bleed and pump and hold methods. We will also discuss final steps and tips for preventing air from entering the brake system in the future.

Causes of Air in Brake Lines

Air can enter the brake system through various means, leading to reduced braking performance and a spongy brake pedal feel. Understanding the common causes of air in brake lines is essential for preventing and addressing this issue.

Worn Seals and Hoses

Over time, the seals and hoses in the brake system can deteriorate, allowing air to enter. The (Brake Hoses, Deteriorate, From the Inside) EAV triplet highlights this issue. As brake hoses age, they can develop cracks or become porous, providing a pathway for air to infiltrate the system. Similarly, worn seals in the master cylinder or calipers can fail, leading to (Master Cylinder Seal Failure, Causes, Air in Brake Lines).

Fluid Leaks

Brake fluid leaks are another common cause of air in the brake lines. (Brake Fluid Leaks, Allow, Air Into System) describes this relationship. When a leak occurs, brake fluid escapes, and air can be drawn into the system to replace the lost fluid. Leaks can occur at various points, such as brake line fittings, caliper seals, or wheel cylinder seals. Identifying and repairing leaks promptly is crucial to prevent air from entering the brake lines.

Low Fluid Level

Maintaining the proper brake fluid level in the master cylinder reservoir is essential for preventing air from entering the system. If the fluid level drops too low, air can be drawn into the master cylinder when the brake pedal is released. (Brake Pad Wear, Causes, Fluid Level to Drop) illustrates this relationship. As brake pads wear down, the caliper pistons extend further, displacing more fluid. If the reservoir is not topped off regularly, the fluid level can drop, allowing air to enter the system.

Improper Brake Fluid

Using the incorrect type of brake fluid can also contribute to air in the brake lines. (Improper Brake Fluid, Eats, Seals) and (Seal Damage, Causes, Air Intrusion) describe this cause-and-effect relationship. Different brake systems require specific types of brake fluid, such as DOT 3, DOT 4, or DOT 5. Using the wrong fluid can cause seals to deteriorate, leading to leaks and air intrusion. Always refer to your vehicle's owner's manual or consult a professional to ensure you are using the correct brake fluid for your system.

Preparing the Brake System

Before attempting to remove air from the brake lines, it is essential to properly prepare the brake system. This ensures a safe and effective process, minimizing the risk of introducing additional air or causing damage to the components.

Parking the Vehicle

Begin by parking the vehicle on a level surface and engaging the parking brake. A stable and level surface prevents the vehicle from rolling and allows for accurate brake fluid level monitoring. (Repair Attempt, Requires, Proper Tools and Equipment) emphasizes the importance of having the right setup for the task.

Removing the Wheels

To access the brake calipers or wheel cylinders, remove the wheels. This step provides clear access to the bleeder screws, which are essential for the air removal process. Ensure that the vehicle is properly supported on jack stands or a lift before removing the wheels.

Checking Brake Fluid Level

Locate the brake fluid reservoir under the hood and remove the cap. Check the fluid level and top off with fresh brake fluid if needed. (Brake System, Uses, Brake Fluid) highlights the importance of using the correct fluid. Maintaining the proper fluid level throughout the process is crucial to prevent air from entering the system. If the reservoir runs dry during the bleeding process, more air will be introduced, undermining your efforts.

| Preparation Step | Purpose |

|---|---|

| Park on level surface | Ensures vehicle stability and accurate fluid level monitoring |

| Remove wheels | Provides access to brake calipers or wheel cylinders |

| Check brake fluid level | Ensures proper fluid level and prevents air introduction |

Gravity Bleed Method

The gravity bleed method is a simple and effective way to remove air from brake lines without the need for a helper. This method relies on the natural force of gravity to draw the air and fluid out of the system.

Attaching Hose to Bleeder Screw

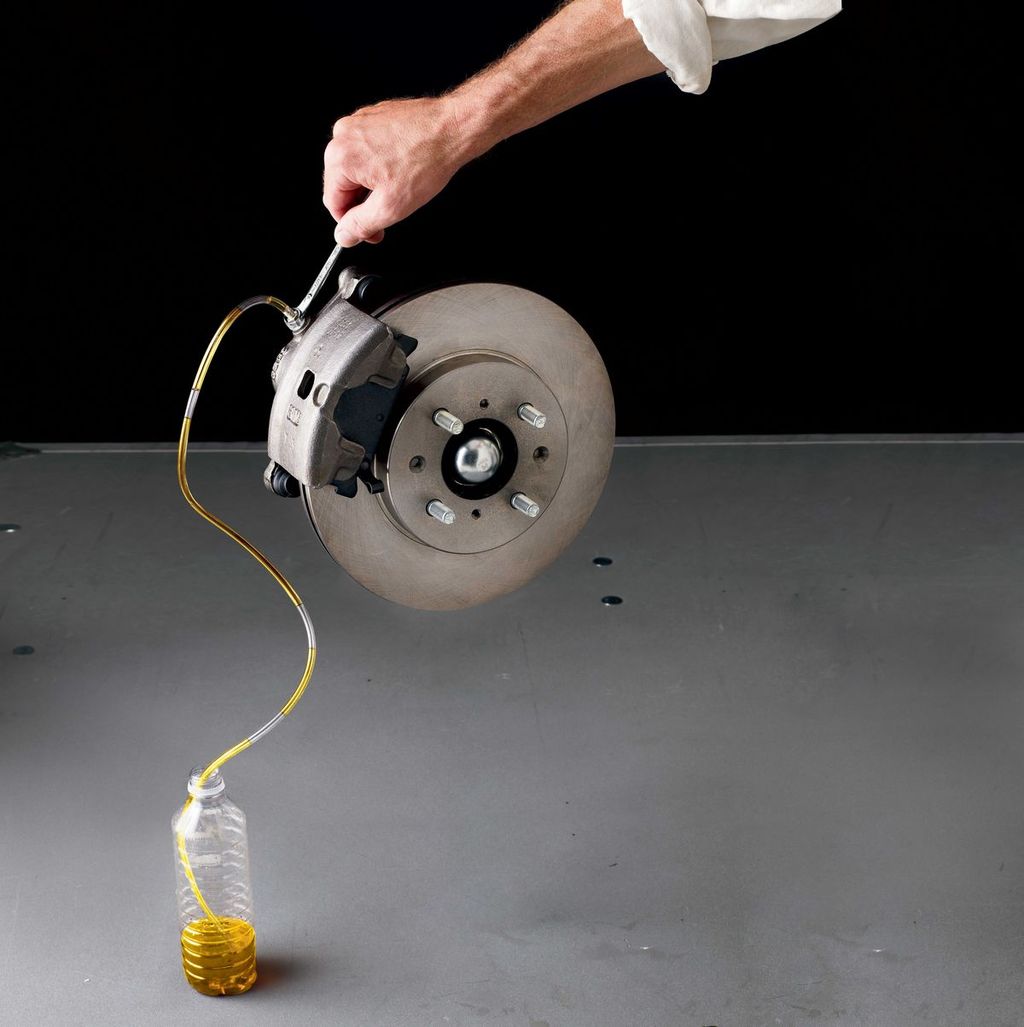

Start by attaching a clear plastic hose to the bleeder screw of the brake caliper or wheel cylinder furthest from the master cylinder. Place the other end of the hose into a container partially filled with clean brake fluid. The clear hose allows you to visually monitor the fluid and air bubbles as they exit the system.

Opening Bleeder Screw

Using a wrench, open the bleeder screw about 1/4 to 1/2 turn. As you open the screw, brake fluid and any trapped air bubbles should begin flowing out of the hose into the container. (Bleeding Brakes, Removes, Air) and (Bleeding Brakes, Restores, Firm Brake Pedal) describe the purpose and outcome of this step.

Tapping Brake Lines and Calipers

While the bleeder screw is open, gently tap on the brake lines and calipers with a rubber mallet. This action helps dislodge any trapped air pockets, allowing them to escape through the bleeder screw. Be cautious not to damage the components while tapping.

Monitoring Fluid Level

As the fluid flows out of the bleeder screw, keep a close eye on the fluid level in the master cylinder reservoir. Top off the reservoir as needed to prevent it from running dry. (Brake System, Includes, Brake Lines) and (Brake Lines, Contains, Air) emphasize the interconnected nature of the system and the importance of maintaining the proper fluid level.

Closing Bleeder Screw

Once the fluid stream flowing from the bleeder screw no longer contains air bubbles, close the bleeder screw and remove the hose. Tighten the screw securely to prevent any fluid leaks or air intrusion.

Repeating Process on Remaining Calipers/Wheel Cylinders

Repeat the gravity bleed process on the remaining brake calipers or wheel cylinders, working your way from the one furthest from the master cylinder to the one closest. This sequence ensures that air is effectively purged from the entire brake system.

The gravity bleed method is summarized in the following steps:

Attach clear hose to bleeder screw and place other end in container with brake fluid

Open bleeder screw 1/4 to 1/2 turn

Tap brake lines and calipers to dislodge air pockets

Monitor and maintain fluid level in master cylinder reservoir

Close bleeder screw when fluid stream is free of air bubbles

Repeat process on remaining calipers/wheel cylinders, working from furthest to closest

Pump and Hold Method

The pump and hold method is another technique for removing air from brake lines without bleeding, but it requires the assistance of a helper. This method involves pumping the brake pedal to build pressure and holding it while opening and closing the bleeder screw.

Assisting with a Helper

Have a helper sit in the driver's seat to operate the brake pedal while you work on the brake calipers or wheel cylinders. (Traditional Brake Bleeding, Requires, Helper) highlights the difference between this method and the gravity bleed method.

Attaching Hose to Bleeder Screw

As with the gravity bleed method, attach a clear hose to the bleeder screw of the brake caliper or wheel cylinder furthest from the master cylinder. Place the other end of the hose in a container to catch the expelled fluid and air.

Opening Bleeder Screw

Open the bleeder screw approximately 1/4 turn. (Air, Causes, Spongy Brake Pedal) and (Air, Reduces, Braking Performance) underscore the importance of removing air from the system to restore proper brake function.

Pumping Brake Pedal

Instruct your helper to slowly press the brake pedal to the floor. As they do so, the pressure in the system will force the air and fluid out through the open bleeder screw.

Closing Bleeder Screw

While your helper holds the brake pedal firmly to the floor, close the bleeder screw. Then, have your helper release the brake pedal. (Pressure Bleeding, Uses, Force) and (Pressure Bleeding, Pushes, Air Out) describe the mechanism behind this method.

Repeating Process on Remaining Calipers/Wheel Cylinders

Repeat the pump and hold process on the remaining brake calipers or wheel cylinders, moving from the furthest to the closest to the master cylinder. Remember to top off the master cylinder reservoir as needed to prevent it from running dry.

| Pump and Hold Method Steps |

|---|

| 1. Assist with a helper to operate brake pedal |

| 2. Attach clear hose to bleeder screw and place other end in container |

| 3. Open bleeder screw 1/4 turn |

| 4. Helper slowly presses brake pedal to the floor |

| 5. Close bleeder screw while helper holds brake pedal down |

| 6. Helper releases brake pedal |

| 7. Repeat process on remaining calipers/wheel cylinders |

Final Steps

After completing the air removal process using either the gravity bleed or pump and hold method, there are a few final steps to ensure your brake system is functioning properly and safely.

Verifying Brake Pedal Feel

With the air removed from the brake lines, the brake pedal should feel firm when depressed. Pump the brakes several times to confirm that the pedal remains firm and does not feel spongy or soft. (Repair Attempt, Requires, Basic Mechanical Skills) emphasizes the importance of verifying the repair's success.

Topping Off Master Cylinder Reservoir

Check the master cylinder reservoir and top off the brake fluid to the "Full" line if necessary. Replace the reservoir cap securely to prevent contamination and fluid loss.

Reinstalling Wheels

Reinstall the wheels and torque the lug nuts to the manufacturer's specified value. Proper torque ensures the wheels are securely fastened and prevents vibrations or loosening while driving.

Test Driving the Vehicle

Before driving at highway speeds, test drive the vehicle at low speeds to confirm that the brakes are functioning properly. Apply the brakes gently and progressively to ensure smooth and effective braking. If any issues are detected, such as a soft pedal or reduced braking performance, do not continue driving and seek professional assistance.

Preventing Air from Entering Brake System

Preventing air from entering the brake system is crucial for maintaining optimal braking performance and safety. By following a few key practices, you can minimize the risk of air infiltration and extend the life of your brake components.

Maintaining Proper Fluid Level

Regularly check the brake fluid level in the master cylinder reservoir and top off as needed. (Brake Pad Wear, Causes, Caliper Pistons to Extend) and (Brake Pad Wear, Causes, Fluid Level to Drop) highlight the relationship between brake pad wear and fluid level. As brake pads wear down, the caliper pistons extend further, causing the fluid level to drop. Keeping the reservoir filled to the proper level prevents air from being drawn into the system.

Avoiding Pressing Brake Pedal to the Floor

When the brake fluid level is low, avoid pressing the brake pedal all the way to the floor. Doing so can allow air to enter the master cylinder, contaminating the entire brake system. If you suspect the fluid level is low or experience a spongy pedal, check the reservoir and top off the fluid before driving.

Replacing Old Brake Fluid

Over time, brake fluid absorbs moisture from the atmosphere, which can lead to corrosion and decreased braking performance. (Old Brake Fluid, Absorbs, Water) and (Water Absorption, Lowers, Boiling Point) describe this process. To prevent these issues, replace the brake fluid according to the manufacturer's recommended maintenance schedule. Fresh, uncontaminated fluid helps maintain optimal braking performance and prevents air from entering the system due to fluid degradation.

Repairing Fluid Leaks Promptly

If you notice any brake fluid leaks, address them promptly to prevent air from entering the system. (Brake Fluid Leaks, Allow, Air Into System) emphasizes the direct relationship between leaks and air infiltration. Regularly inspect brake lines, hoses, calipers, and wheel cylinders for signs of leakage, such as wet spots or puddles of fluid. If a leak is detected, have it repaired by a professional mechanic to ensure the integrity of your brake system.

By following these preventive measures, you can significantly reduce the likelihood of air entering your brake lines, maintaining optimal braking performance and safety.

Conclusion

Removing air from brake lines without bleeding is a valuable skill for DIY enthusiasts and those who want to maintain their vehicle's braking system. By understanding the causes of air in brake lines and following the gravity bleed or pump and hold methods, you can effectively eliminate air and restore proper brake function. Remember to always prioritize safety, use the correct tools and equipment, and seek professional assistance if you encounter any issues or are unsure about the process. Regular brake maintenance, including checking fluid levels and replacing old fluid, is essential for preventing air from entering the system and ensuring reliable braking performance.

FAQs

What are the signs of air in brake lines?

Signs of air in brake lines include a spongy or soft brake pedal feel, reduced braking performance, and an increased stopping distance. If you experience these symptoms, it's essential to address the issue promptly to ensure safe braking.

Can I use any type of fluid to top off the brake fluid reservoir?

No, it is crucial to use the correct type of brake fluid specified by your vehicle's manufacturer. Using the wrong fluid can cause damage to seals and other components, leading to leaks and air intrusion.

How often should I replace my brake fluid?

The recommended interval for replacing brake fluid varies depending on your vehicle's make and model. Consult your owner's manual or a professional mechanic to determine the appropriate schedule for your vehicle.

What tools do I need to perform the gravity bleed or pump and hold methods?

To perform the gravity bleed or pump and hold methods, you will need a clear plastic hose, a container for catching the expelled fluid, a wrench to open and close the bleeder screws, and fresh brake fluid for topping off the reservoir. Having a rubber mallet for tapping the brake lines and calipers can also be helpful.

Can I reuse the old brake fluid that I've expelled during the bleeding process?

No, it is not recommended to reuse old brake fluid as it may be contaminated with air, moisture, or debris. Always dispose of the expelled fluid properly and use fresh, clean brake fluid when topping off the reservoir.

How do I know if I have a brake fluid leak?

Signs of a brake fluid leak include wet spots or puddles of fluid near the brake components, such as the brake lines, calipers, or wheel cylinders. You may also notice a low fluid level in the master cylinder reservoir or a gradual decrease in braking performance.

Can I drive my vehicle immediately after removing air from the brake lines?

After removing air from the brake lines, it is essential to test drive the vehicle at low speeds to ensure proper brake function before driving at highway speeds. If you notice any issues, such as a soft pedal or reduced braking performance, do not continue driving and seek professional assistance.

How often should I check my brake fluid level?

It is recommended to check your brake fluid level at least once a month or as specified in your vehicle's owner's manual. Regularly monitoring the fluid level can help you detect leaks or low fluid conditions early, preventing air from entering the system.

What should I do if I accidentally press the brake pedal to the floor when the fluid level is low?

If you accidentally press the brake pedal to the floor when the fluid level is low, air may have entered the master cylinder. In this case, it is advisable to have a professional mechanic inspect and bleed the entire brake system to ensure proper function and safety.

Can I use the gravity bleed method on all types of vehicles?

The gravity bleed method can be used on most vehicles with hydraulic brake systems. However, some vehicles may have specific bleeding procedures or require special tools. Always consult your vehicle's owner's manual or a professional mechanic to determine the appropriate method for your make and model.

Bình luận (0)

Bài viết đề xuất

Transmission fluid plays a crucial role in the proper functioning of a vehicle's transmission system. It lubricates the moving parts, transfers power, and helps to cool the transmission components.

Mufflers are a crucial component of a vehicle's exhaust system, responsible for reducing the noise generated by the engine. Their primary function is to muffle or dampen the loud and disruptive sounds produced by the rapid combustion of fuel and the subsequent expulsion of exhaust gases.

As an experienced automotive mechanic, I've encountered numerous cases where a seemingly minor issue like a hole in the muffler can lead to more significant problems, including engine misfires.

Bài viết liên quan

Gravity bleeding is a method of removing air from your vehicle's brake lines, ensuring optimal brake performance and safety. This process involves allowing the brake fluid to flow through the system using gravity, effectively purging any air bubbles that may cause a spongy brake pedal feel or reduced braking efficiency. In this comprehensive guide, we will walk you through the tools and materials needed, the step-by-step procedure, troubleshooting tips, and the benefits of regular brake maintenance.

Is your brake caliper stuck, causing brake drag and overheating? Don't let it stop you in your tracks. This article will guide you through a quick temporary fix for a seized brake caliper that can get you back on the road safely until you can get a proper repair.

Pushing back a brake piston without a special tool is possible with some ingenuity and common household items. This article will guide you through the process, providing step-by-step instructions and helpful tips to ensure a successful brake piston retraction. We'll cover the importance of brake maintenance, understanding brake pistons, traditional methods of pushing back brake pistons, and various techniques to push back brake pistons without a tool. Additionally, we'll address common issues and the benefits of performing this task yourself.

The parking brake light is an essential warning indicator in your vehicle that alerts you when the parking brake is engaged or if there's an issue with the braking system. If you notice that your parking brake light won't turn off, even after disengaging the parking brake, it's crucial to address the problem promptly to ensure your safety on the road. In this article, we'll guide you through the steps to reset your parking brake light and discuss the potential causes behind this issue.

If you're wondering how to reset your car's ABS light without a scan tool, you've come to the right place. In this article, we'll provide you with a step-by-step guide on how to turn off the ABS light using easy DIY methods, saving you time and money. We'll also discuss the causes of ABS light issues and how to fix them like a pro.

Installing anti-rattle clips on your brake pads is a simple DIY task that can significantly reduce brake noise and vibration, improve safety, and extend the life of your brake system. This comprehensive guide will walk you through the process step-by-step, providing you with the knowledge and confidence to tackle this project on your own.

The front port on the master cylinder is the one that connects to the front brakes. It plays a crucial role in the brake system, ensuring that the front brakes receive the necessary hydraulic pressure to function properly. In this article, we will explore the importance of the front port, its design, and how it relates to overall brake performance and safety. We will also cover the differences between the front and rear ports, maintenance requirements, and troubleshooting tips for common issues like brake squealing when reversing.

Brake squeaking when reversing is a common issue that many vehicle owners face. This annoying noise not only disrupts the peace but also raises concerns about the braking system's health. In this article, we will explore the causes of brake squeaking in reverse, how to diagnose the problem, and provide practical solutions to achieve silent braking.

When it comes to brake lines, choosing the right flare type is crucial for ensuring a strong, leak-free connection that can withstand the high pressures present in automotive brake systems. In this article, we'll explore the differences between single flare, double flare (SAE), and bubble flare (ISO/DIN) brake lines, helping you determine which type is best suited for your vehicle.