A brake dynamometer is a crucial tool in the automotive industry, used to measure and analyze the performance of a vehicle's braking system. By applying a controlled braking force to the rotating shaft or drum and measuring the torque required to hold the shaft stationary at various speeds, brake dynamometers provide valuable insights into the effectiveness, efficiency, and safety of a vehicle's brakes. This article will delve into the various types of brake dynamometers, their working principles, the components they test, and the performance metrics they measure. We will also explore the applications of brake dynamometers in the automotive industry and discuss the advancements and future trends in this technology.

Single Flare Vs Double Flare Vs Bubble Flare Brake Lines

Single Flare Vs Double Flare Vs Bubble Flare Brake Lines

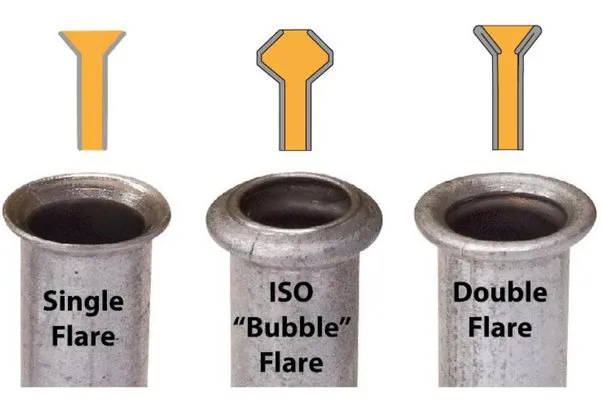

When it comes to brake lines, choosing the right flare type is crucial for ensuring a strong, leak-free connection that can withstand the high pressures present in automotive brake systems. In this article, we'll explore the differences between single flare, double flare (SAE), and bubble flare (ISO/DIN) brake lines, helping you determine which type is best suited for your vehicle.

Introduction to Brake Line Flare Types

Importance of Choosing the Right Flare Type

Selecting the appropriate flare type for your brake lines is essential for maintaining a safe and reliable braking system. The flare type determines the strength of the connection, its ability to resist leaks, and its compatibility with various fittings and applications.

Brief Overview of Single, Double, and Bubble Flares

Brake line flares come in three main types: single flare, double flare (SAE), and bubble flare (ISO/DIN). Each type has its own unique characteristics, advantages, and disadvantages, which we will explore in detail throughout this article.

Single Flare Brake Lines

Flare Angle and Sealing Surface

Single flare brake lines feature a 45-degree flare angle, which creates a sealing surface when connected to a fitting. However, this single flare design is not considered strong enough to withstand the high pressures found in automotive brake systems.

Advantages and Disadvantages

While single flares are relatively easy to form and require simple flaring tools, they are not suitable for use in brake lines due to their limited strength and sealing capabilities.

Why Single Flares Are Not Suitable for Brake Lines

Single flares cannot provide the necessary strength and leak-free connection required for the extreme pressures present in brake lines. Using single flares in a brake system can lead to fluid leaks, reduced braking performance, and potential safety hazards.

Double Flare SAE Brake Lines

Flare Angle and Sealing Surface

SAE double flares, also known as inverted flares, feature a 90-degree inverted flare angle. This design creates a sealing surface on both the angled portion of the flare and the inverted lip, providing a strong and leak-free connection.

Two-Step Formation Process

Creating a double flare involves a two-step process using a double flaring tool. First, the brake line is formed into a single flare, and then the tool folds the flare inward, creating the characteristic inverted double flare shape.

Advantages and Disadvantages

Double flares offer several advantages, including:

Strong, leak-free connection

Ability to handle high pressures in brake systems

Compatibility with a wide range of fittings and applications

However, forming double flares requires a specialized double flaring tool and a bit more skill compared to single flares.

Compatible Fittings and Applications

SAE double flares are compatible with a variety of fittings, including:

45-degree SAE fittings

37-degree JIC fittings

Inverted flare adapters

Double flares are suitable for use in brake lines, fuel lines, and other high-pressure applications.

Most Common in American and Asian Vehicles

SAE double flares are the most common type of brake line flare found in American and Asian vehicles. They are widely used due to their strength, reliability, and compatibility with various fittings and applications.

Bubble Flare ISO/DIN Brake Lines

Flare Angle and Sealing Surface

ISO/DIN bubble flares feature a convex "bubble" shape at the end of the brake line. This design creates a sealing surface that mates with an angled surface in the corresponding fitting.

Single-Step Formation Process

Unlike double flares, bubble flares are created in a single step using a specialized bubble flaring tool. This process involves forming the brake line into the characteristic convex shape.

Advantages and Disadvantages

Bubble flares offer some advantages, such as:

Compatibility with ISO/DIN fittings commonly found in European vehicles

Ability to reseal to some extent

However, bubble flares have a reputation for a more limited lifespan compared to double flares and may not provide the same level of long-term reliability.

Compatible Fittings and Applications

ISO/DIN bubble flares are designed to work with specific fittings, including:

ISO/DIN bubble flare fittings

Metric bubble flare adapters

Bubble flares are primarily used in brake lines and other high-pressure applications in European vehicles.

More Common in European Vehicles

ISO/DIN bubble flares are more commonly found in European vehicles, as they are the standard flare type used by many European manufacturers.

Comparison of Double and Bubble Flare Brake Lines

To better understand the differences between double flares and bubble flares, let's compare them across several key factors:

| Factor | Double Flare (SAE) | Bubble Flare (ISO/DIN) |

|---|---|---|

| Cracking Susceptibility | Low | Moderate |

| Vibration Resistance | High | Moderate |

| Stress Distribution | Even | Less Even |

| Ease of Formation | Moderate | Easy |

| Regional Popularity | American and Asian | European |

Cracking Susceptibility

Double flares are less susceptible to cracking compared to bubble flares, thanks to their inverted design and even stress distribution.

Vibration Resistance

The strong, leak-free connection provided by double flares offers high resistance to vibration, ensuring a more reliable seal in demanding conditions.

Stress Distribution

Double flares distribute stress more evenly across the flare, reducing the risk of failure and leaks. Bubble flares, on the other hand, may experience less even stress distribution.

Ease of Formation

Bubble flares are generally easier to form than double flares, as they require a single-step process using a specialized bubble flaring tool. Double flares involve a two-step process and require a double flaring tool.

Regional Popularity

As mentioned earlier, double flares are more popular in American and Asian vehicles, while bubble flares are more common in European vehicles.

Brake Line Tubing Materials and Pressure Ratings

Brake lines are typically made from either copper or stainless steel tubing, each with its own pressure ratings and characteristics.

Copper Tubing

Copper brake lines are known for their ease of installation and resistance to corrosion. They are rated for pressures up to 1,000 psi and are suitable for most standard brake systems.

Stainless Steel Tubing

Stainless steel brake lines offer superior strength and durability compared to copper lines. They can handle pressures up to 1,500 psi and are often used in high-performance or racing applications.

| Material | Pressure Rating (psi) |

|---|---|

| Copper | 1,000 |

| Stainless Steel | 1,500 |

Flaring Tools and Techniques

To create reliable and leak-free brake line connections, it's essential to use the appropriate flaring tools and techniques for each flare type.

Double Flare Tools

Double flare tools are designed to create SAE double flares in a two-step process. These tools typically consist of a base, a clamping mechanism, and a flaring bar with a 45-degree and a 90-degree flaring bit.

Bubble Flare Tools

Bubble flare tools are used to create ISO/DIN bubble flares in a single step. These tools feature a base, a clamping mechanism, and a flaring bit with a convex shape that forms the characteristic bubble flare.

Importance of Flare Quality and Tool Condition

The quality of the flare and the condition of the flaring tool directly impact the strength and reliability of the brake line connection. It's crucial to use high-quality flaring tools that are in good condition to ensure proper flare formation and minimize the risk of leaks or failures.

Factors Affecting Brake Line Performance and Reliability

Several factors can influence the performance and reliability of brake lines, regardless of the flare type used:

Flare Quality

A properly formed flare is essential for creating a strong, leak-free connection. Flares should be free of cracks, burrs, and other imperfections that could compromise the seal.

Material Compatibility

Brake lines and fittings should be made from compatible materials to prevent corrosion and ensure a long-lasting connection. For example, copper lines should be used with brass fittings, while stainless steel lines should be paired with stainless steel fittings.

Corrosion Resistance

Corrosion can weaken brake lines and lead to leaks or failures. Using corrosion-resistant materials, such as stainless steel or coated copper lines, can help extend the life of the brake system.

Proper Installation Techniques

Following proper installation techniques is crucial for ensuring reliable brake line connections. This includes:

Using the correct flaring tool for the flare type

Properly cleaning and preparing the brake line before flaring

Avoiding overtightening or undertightening the fittings

Routing the brake lines away from heat sources and moving components

Conclusion

In summary, when it comes to brake lines, both SAE double flares and ISO/DIN bubble flares provide strong, leak-free connections suitable for the high pressures found in automotive brake systems. Single flares, however, should never be used in brake lines due to their insufficient strength and sealing capabilities.

Choosing the best flare type for your vehicle depends on factors such as the vehicle's origin (American, Asian, or European), the fittings used, and the specific application. Regardless of the flare type selected, using high-quality flaring tools and proper installation techniques is essential for ensuring safe and dependable brake system performance.

By understanding the differences between single flare, double flare, and bubble flare brake lines, you can make an informed decision when replacing or upgrading your vehicle's brake lines, ultimately contributing to a safer and more reliable braking system.

FAQs

What is the torque specification for tightening brake line flare fittings?

The torque specification varies depending on the flare type and fitting size. Always refer to the vehicle manufacturer's recommendations or consult a reliable repair manual for the correct torque values.

Can I mix different types of flares in my brake system?

No, it is not recommended to mix different flare types in a brake system. Always use the same flare type throughout the system to ensure proper sealing and compatibility.

How often should I replace my vehicle's brake lines?

The replacement interval for brake lines depends on factors such as the vehicle's age, driving conditions, and the brake line material. As a general rule, inspect brake lines regularly and replace them if you notice any signs of corrosion, damage, or leaks.

Can I use the same flaring tool for both SAE and ISO flares?

No, SAE and ISO flares require different flaring tools. Make sure to use the appropriate tool for each flare type to ensure proper flare formation and sealing.

Is it necessary to use a tubing cutter when cutting brake lines?

Yes, using a tubing cutter is recommended when cutting brake lines. This ensures a clean, square cut and minimizes the risk of damaging the tubing or creating burrs that could interfere with proper flare formation.

Can I reuse brake line fittings when replacing brake lines?

It is generally not recommended to reuse brake line fittings, as they may be worn or damaged. Always use new fittings that match the flare type and size of the new brake lines.

What should I do if I accidentally overtighten a brake line fitting?

If you accidentally overtighten a brake line fitting, do not attempt to loosen it, as this may damage the flare or fitting. Instead, replace the fitting and the affected portion of the brake line to ensure a proper, leak-free connection.

Can I use Teflon tape or thread sealant on brake line fittings?

No, do not use Teflon tape or thread sealant on brake line fittings. The flare itself is designed to create a leak-free seal, and using additional sealants may interfere with the proper seating of the flare or contaminate the brake fluid.

How can I tell if a brake line is properly flared?

A properly flared brake line should have a smooth, even flare without any cracks, splits, or irregularities. The flare should sit flush against the fitting, and there should be no gaps or visible damage to the tubing or fitting.

What should I do if I notice a leak in my brake system after replacing brake lines?

If you notice a leak in your brake system after replacing brake lines, do not drive the vehicle. Inspect the brake lines and fittings for any signs of damage, improper flaring, or loose connections. If necessary, re-flare the lines or replace the fittings to resolve the leak.

Bình luận (0)

Bài viết đề xuất

The diagnostic trouble code (DTC) P03CE indicates an issue with the pressure variation in cylinder 6 of the engine. Specifically, it means that the pressure variation in cylinder 6 is lower than expected. This code is related to the cylinder pressure monitoring system, which is designed to detect abnormal combustion conditions in each cylinder.

Hydraulic brake systems have become an integral part of modern vehicles, ensuring reliable and efficient braking power. This comprehensive guide delves into the inner workings, advantages, and maintenance requirements of these crucial systems, providing a deep understanding of their importance in safe and efficient vehicle operation.

The illumination of the check charging system light on your vehicle's dashboard is a warning sign that should not be disregarded. This indicator signals an issue with the charging system, which is crucial for maintaining the battery's charge and providing electrical power to various components. Neglecting this warning can lead to a drained battery, electrical component failures, and potential safety hazards if your vehicle stalls unexpectedly.

Bài viết liên quan

Gravity bleeding is a method of removing air from your vehicle's brake lines, ensuring optimal brake performance and safety. This process involves allowing the brake fluid to flow through the system using gravity, effectively purging any air bubbles that may cause a spongy brake pedal feel or reduced braking efficiency. In this comprehensive guide, we will walk you through the tools and materials needed, the step-by-step procedure, troubleshooting tips, and the benefits of regular brake maintenance.

Is your brake caliper stuck, causing brake drag and overheating? Don't let it stop you in your tracks. This article will guide you through a quick temporary fix for a seized brake caliper that can get you back on the road safely until you can get a proper repair.

Pushing back a brake piston without a special tool is possible with some ingenuity and common household items. This article will guide you through the process, providing step-by-step instructions and helpful tips to ensure a successful brake piston retraction. We'll cover the importance of brake maintenance, understanding brake pistons, traditional methods of pushing back brake pistons, and various techniques to push back brake pistons without a tool. Additionally, we'll address common issues and the benefits of performing this task yourself.

The parking brake light is an essential warning indicator in your vehicle that alerts you when the parking brake is engaged or if there's an issue with the braking system. If you notice that your parking brake light won't turn off, even after disengaging the parking brake, it's crucial to address the problem promptly to ensure your safety on the road. In this article, we'll guide you through the steps to reset your parking brake light and discuss the potential causes behind this issue.

If you're wondering how to reset your car's ABS light without a scan tool, you've come to the right place. In this article, we'll provide you with a step-by-step guide on how to turn off the ABS light using easy DIY methods, saving you time and money. We'll also discuss the causes of ABS light issues and how to fix them like a pro.

Installing anti-rattle clips on your brake pads is a simple DIY task that can significantly reduce brake noise and vibration, improve safety, and extend the life of your brake system. This comprehensive guide will walk you through the process step-by-step, providing you with the knowledge and confidence to tackle this project on your own.

The front port on the master cylinder is the one that connects to the front brakes. It plays a crucial role in the brake system, ensuring that the front brakes receive the necessary hydraulic pressure to function properly. In this article, we will explore the importance of the front port, its design, and how it relates to overall brake performance and safety. We will also cover the differences between the front and rear ports, maintenance requirements, and troubleshooting tips for common issues like brake squealing when reversing.

Brake squeaking when reversing is a common issue that many vehicle owners face. This annoying noise not only disrupts the peace but also raises concerns about the braking system's health. In this article, we will explore the causes of brake squeaking in reverse, how to diagnose the problem, and provide practical solutions to achieve silent braking.

When it comes to brake lines, choosing the right flare type is crucial for ensuring a strong, leak-free connection that can withstand the high pressures present in automotive brake systems. In this article, we'll explore the differences between single flare, double flare (SAE), and bubble flare (ISO/DIN) brake lines, helping you determine which type is best suited for your vehicle.