Automotive coolants are essential for regulating engine temperatures, but some formulations contain ethylene glycol, a toxic substance that can cause severe poisoning if ingested. This article explores the dangers of ethylene glycol toxicity, its symptoms, treatment options, and safer alternatives like propylene glycol. We'll also discuss preventive measures to protect children, pets, and the environment from accidental exposure.

Integrated Brake Systems: Enhancing Vehicle Safety and Performance

Integrated Brake Systems: Enhancing Vehicle Safety and Performance

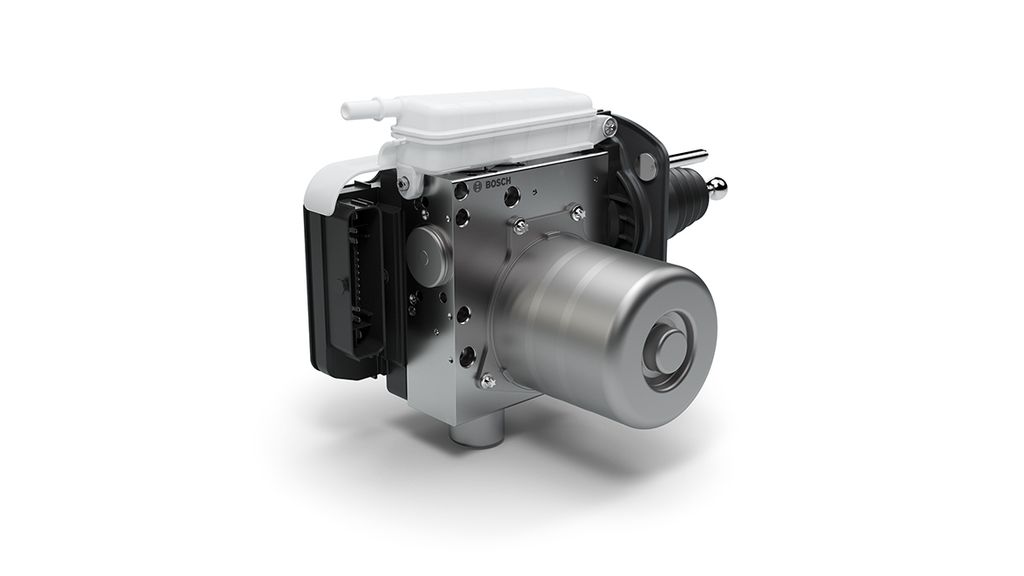

Integrated brake systems (IBS) represent a significant advancement in automotive braking technology, combining multiple braking functions into a single, compact unit. This innovative approach to braking offers numerous benefits, including improved safety, efficiency, and performance. In this article, we will explore the key features and advantages of integrated brake systems, their components and functionality, and their impact on the future of the automotive industry.

We will begin by discussing the definition and importance of integrated brake systems in modern vehicles. Then, we will delve into the components and functionality of IBS, followed by an examination of the performance advantages they offer. We will also explore how IBS contributes to enhanced vehicle safety and supports the development of automated driving systems. Additionally, we will discuss the compatibility and adoption of IBS in various vehicle types, as well as maintenance and diagnostic considerations. Finally, we will look at future developments and trends in the field of automotive braking technology.

I. Introduction

Integrated brake systems (IBS) are an advanced braking technology that combines multiple braking functions into a single, compact unit. This innovative approach streamlines the braking system, reducing weight and complexity while improving overall performance. IBS represents a significant step forward in automotive braking technology, offering benefits such as faster and more precise brake pressure buildup, improved emergency braking performance, and the ability to support advanced features like brake blending in electric vehicles.

The importance of integrated brake systems in modern vehicles cannot be overstated. As vehicles become increasingly electrified and automated, the demands placed on braking systems continue to grow. IBS provides a solution that meets these demands, offering enhanced safety, efficiency, and performance in a more compact and streamlined package. By combining key braking functions into a single unit, IBS reduces the number of components required, leading to weight savings and improved reliability.

II. Components and Functionality

A. Key components of integrated brake systems

Integrated brake systems combine two essential braking functions: brake force boosting and electronic stability control (ESC). Brake force boosting amplifies the force applied by the driver to the brake pedal, ensuring sufficient braking power is available when needed. Electronic stability control, on the other hand, helps maintain vehicle stability and control during emergency maneuvers or in adverse driving conditions. By integrating these two functions into a single unit, IBS provides a more efficient and effective braking solution.

B. Elimination of separate components

One of the primary advantages of integrated brake systems is the elimination of separate components that are typically found in traditional braking systems. IBS does away with the need for a separate vacuum brake booster, vacuum pump, and ESC module. This consolidation of components reduces the overall weight and complexity of the braking system, leading to improved efficiency and reliability.

| Component | Traditional Braking System | Integrated Brake System |

|---|---|---|

| Vacuum Brake Booster | Required | Eliminated |

| Vacuum Pump | Required | Eliminated |

| ESC Module | Separate Unit | Integrated |

C. Benefits of component integration

The integration of key braking components in IBS offers several benefits. Firstly, it reduces the weight and complexity of the braking system, as mentioned earlier. This weight reduction can contribute to improved fuel efficiency and overall vehicle performance. Secondly, IBS provides vacuum-independent, electro-hydraulic braking, which is particularly beneficial for hybrid and electric vehicles that may not have a consistent vacuum source. This ensures reliable and consistent braking performance regardless of the vehicle's propulsion system.

III. Performance Advantages

A. Faster and more precise brake pressure buildup

Integrated brake systems offer faster and more precise brake pressure buildup compared to traditional braking systems. This is achieved through the use of advanced electro-hydraulic actuators and control algorithms that can modulate brake pressure more quickly and accurately. The result is improved responsiveness and a shorter time required to reach maximum braking force, which can be crucial in emergency braking situations.

B. Improved emergency braking performance

The faster and more precise brake pressure buildup provided by IBS translates into improved emergency braking performance. In fact, studies have shown that vehicles equipped with integrated brake systems can potentially stop up to 9 meters shorter from 100 km/h compared to those with conventional braking systems. This significant reduction in stopping distance can mean the difference between avoiding a collision and experiencing a severe accident.

| Braking System | Stopping Distance from 100 km/h |

|---|---|

| Conventional | 40 meters |

| Integrated | 31 meters |

C. Advanced features enabled by IBS

Integrated brake systems enable the implementation of advanced features that enhance vehicle performance and efficiency. One such feature is brake blending in electric vehicles. IBS allows for the smooth transition between regenerative braking, which recovers energy during deceleration, and traditional friction braking. This seamless blending optimizes energy recovery while maintaining a comfortable and predictable braking feel for the driver.

D. Customization of pedal feel and braking characteristics through software

Another advantage of integrated brake systems is the ability to customize pedal feel and braking characteristics through software. This flexibility allows engineers to tune the braking system to suit different vehicle types and driver preferences. For example, a sports car may be programmed to have a firmer, more responsive brake pedal feel, while a luxury sedan may prioritize a softer, more progressive braking experience. This customization capability enables manufacturers to differentiate their vehicles and cater to specific market segments.

IV. Safety and Automation

A. Enhanced vehicle safety through improved braking performance

Integrated brake systems contribute to enhanced vehicle safety by providing improved braking performance. The faster and more precise brake pressure buildup, combined with the ability to maintain vehicle stability and control during emergency maneuvers, helps reduce the likelihood and severity of accidents. Additionally, the improved stopping distance afforded by IBS can be critical in avoiding collisions altogether.

B. Support for the development of automated driving systems

As the automotive industry moves towards increasingly automated driving systems, integrated brake systems play a crucial role in supporting this development. IBS provides the necessary redundancy and fail-safe operation required for self-driving vehicles. By ensuring reliable and consistent braking performance, even in the event of a system failure, IBS helps create a safe and robust foundation for automated driving technologies.

Redundancy: IBS incorporates multiple layers of redundancy to ensure braking functionality is maintained even if one component fails.

Fail-safe operation: In the event of a system failure, IBS is designed to default to a safe state, ensuring the vehicle can still be brought to a controlled stop.

C. Importance of IBS in future self-driving vehicles

The importance of integrated brake systems in future self-driving vehicles cannot be overstated. As vehicles become increasingly autonomous, the braking system must be able to respond quickly, accurately, and reliably to a wide range of driving situations. IBS provides the necessary performance, safety, and redundancy features to support the development and deployment of self-driving technologies. Without the advanced capabilities offered by IBS, the realization of fully autonomous vehicles would be significantly more challenging.

V. Compatibility and Adoption

A. Suitability for various vehicle types

Integrated brake systems are suitable for a wide range of vehicle types, including both hybrid and electric vehicles as well as conventional gasoline and diesel-powered vehicles. The benefits of IBS, such as improved braking performance, reduced weight, and increased efficiency, are applicable across the automotive spectrum. However, IBS is particularly advantageous for hybrid and electric vehicles, as it provides vacuum-independent braking and enables advanced features like brake blending.

| Vehicle Type | Compatibility with IBS |

|---|---|

| Hybrid | High |

| Electric | High |

| Gasoline | Medium |

| Diesel | Medium |

B. Correlation with advancing automotive technology

The adoption of integrated brake systems is closely correlated with the advancement of automotive technology as a whole. As vehicles become more sophisticated, with increasing levels of electrification and automation, the demand for advanced braking solutions like IBS grows. The capabilities offered by IBS align with the broader trends in the automotive industry, such as the push for greater efficiency, safety, and performance.

C. Growing consumer demand for advanced safety features

Another factor driving the adoption of integrated brake systems is the growing consumer demand for advanced safety features. As awareness of vehicle safety technologies increases, consumers are increasingly seeking out vehicles equipped with the latest and most effective safety systems. IBS, with its improved braking performance and ability to support automated driving functions, meets this demand and helps manufacturers differentiate their vehicles in a competitive market.

VI. Maintenance and Diagnostics

A. Regular maintenance requirements for IBS

While integrated brake systems offer numerous benefits, they also have specific maintenance requirements to ensure optimal performance and longevity. Regular maintenance tasks for IBS include:

Checking and replacing brake fluid at recommended intervals

Inspecting brake pads and rotors for wear and damage

Calibrating and testing electronic components and sensors

B. Specialized diagnostic tools and procedures

Due to the complex nature of integrated brake systems, specialized diagnostic tools and procedures are necessary for troubleshooting and repair. Technicians must be trained in the use of these tools and be familiar with the specific diagnostic protocols for IBS. This specialized knowledge ensures that any issues with the braking system can be accurately identified and resolved in a timely manner.

| Diagnostic Tool | Purpose |

|---|---|

| Diagnostic Scanner | Reads fault codes and monitors system parameters |

| Multimeter | Measures electrical voltage, current, and resistance |

| Oscilloscope | Analyzes waveforms and signals from sensors and actuators |

C. Common issues and troubleshooting techniques

Some common issues that may arise with integrated brake systems include:

Faulty sensors or wiring

Degraded brake fluid

Worn brake pads or rotors

Software glitches or calibration errors

Troubleshooting techniques for these issues often involve the use of diagnostic scanners, multimeters, and oscilloscopes to identify the root cause of the problem. Once identified, repairs may include replacing faulty components, flushing and replacing brake fluid, or updating system software.

VII. Future Developments and Trends

A. Integration with other vehicle systems

As automotive technology continues to advance, the integration of integrated brake systems with other vehicle systems is expected to increase. For example, IBS may be linked with adaptive cruise control, collision avoidance systems, and other advanced driver assistance systems (ADAS) to provide even greater levels of safety and convenience. This integration will allow for more seamless and coordinated control of the vehicle's various functions, enhancing overall performance and user experience.

B. Advancements in sensor technology and control algorithms

Future developments in integrated brake systems will likely be driven by advancements in sensor technology and control algorithms. More sophisticated sensors, such as high-resolution cameras, lidar, and radar, will provide a wealth of data for the braking system to analyze and respond to in real-time. Advanced control algorithms, powered by artificial intelligence and machine learning, will enable the braking system to make more informed and optimized decisions, adapting to a wide range of driving conditions and scenarios.

C. Potential for autonomous braking and collision avoidance

Perhaps the most exciting future development for integrated brake systems is their potential to enable autonomous braking and collision avoidance. As IBS becomes more advanced and integrated with other vehicle systems, it may be possible for the braking system to automatically detect and respond to potential collision situations, applying the brakes without any input from the driver. This autonomous braking capability could significantly reduce the occurrence and severity of accidents, particularly those caused by human error or distraction.

VIII. Conclusion

In conclusion, integrated brake systems represent a major leap forward in automotive braking technology, offering a host of benefits that enhance vehicle safety, performance, and efficiency. By combining multiple braking functions into a single, compact unit, IBS streamlines the braking system, reducing weight and complexity while improving overall braking performance. The faster and more precise brake pressure buildup provided by IBS translates into shorter stopping distances and improved emergency braking capabilities, ultimately contributing to safer vehicles and roads. As the automotive industry continues to evolve, with increasing levels of electrification and automation, the importance of integrated brake systems will only continue to grow. Future developments in sensor technology, control algorithms, and system integration will further expand the capabilities of IBS, potentially enabling autonomous braking and collision avoidance. As such, integrated brake systems are poised to play a crucial role in shaping the future of the automotive landscape, delivering enhanced safety, performance, and convenience to drivers and passengers alike.

FAQs

What is the primary advantage of an integrated brake system compared to traditional braking systems?

The main advantage of an integrated brake system is its ability to combine multiple braking functions, such as brake force boosting and electronic stability control, into a single compact unit. This integration reduces weight, complexity, and cost while improving overall braking performance and efficiency.

How does an integrated brake system contribute to vehicle safety?

Integrated brake systems enhance vehicle safety by providing faster and more precise brake pressure buildup, resulting in shorter stopping distances and improved emergency braking performance. They also support advanced safety features like automatic emergency braking and help maintain vehicle stability during critical maneuvers.

Are integrated brake systems suitable for all types of vehicles?

Yes, integrated brake systems are suitable for a wide range of vehicles, including passenger cars, light commercial vehicles, and heavy commercial vehicles. They are particularly beneficial for hybrid and electric vehicles, as they provide vacuum-independent braking and enable features like brake blending.

How do integrated brake systems support the development of automated driving technologies?

Integrated brake systems play a crucial role in supporting the development of automated driving technologies by providing the necessary redundancy and fail-safe operation required for self-driving vehicles. They ensure reliable and consistent braking performance, even in the event of a system failure, creating a safe foundation for autonomous driving.

What are the maintenance requirements for integrated brake systems?

Integrated brake systems have specific maintenance requirements, including checking and replacing brake fluid at recommended intervals, inspecting brake pads and rotors for wear and damage, and calibrating electronic components and sensors. However, due to their integrated design, they may require less overall maintenance compared to traditional braking systems.

Can integrated brake systems help reduce vehicle emissions?

Yes, integrated brake systems can contribute to reducing vehicle emissions by enabling more efficient regenerative braking in hybrid and electric vehicles, which recovers energy during deceleration. Additionally, their precise control and reduced drag can lead to improved fuel efficiency in conventional vehicles.

How do integrated brake systems improve pedal feel for the driver?

Integrated brake systems can be programmed to provide a customized pedal feel for the driver, offering a more responsive or progressive braking experience based on the vehicle type and driver preferences. This customization is made possible through advanced software control of the braking system.

What role do sensors play in integrated brake systems?

Sensors are crucial components in integrated brake systems, as they provide the necessary data for the system to analyze and respond to various driving situations in real-time. As sensor technology advances, integrated brake systems will become even more capable of adapting to a wide range of conditions and scenarios.

How do integrated brake systems handle the transition between regenerative and friction braking?

Integrated brake systems enable smooth and seamless transitions between regenerative and friction braking, a process known as brake blending. This blending optimizes energy recovery while maintaining a comfortable and predictable braking feel for the driver.

What advancements can we expect in integrated brake systems in the future?

Future advancements in integrated brake systems will likely include greater integration with other vehicle systems, such as adaptive cruise control and collision avoidance, as well as improvements in sensor technology and control algorithms. These developments will further enhance the safety, performance, and efficiency of braking systems, potentially enabling fully autonomous braking and collision avoidance capabilities.

Bình luận (0)

Bài viết đề xuất

The P0021 diagnostic trouble code indicates an issue with the camshaft position sensor or variable valve timing (VVT) system on the engine's bank 2, typically the passenger side bank on V6 and V8 engines. This code signals that the camshaft timing is over-advanced, meaning the camshaft is rotating ahead of its intended position relative to the crankshaft. If left unresolved, this condition can lead to severe internal engine damage.

The "Battery Saver Active" warning light on your vehicle's dashboard indicates a low battery charge condition, prompting the car to enter a power-saving mode. This mode helps conserve the remaining battery power by disabling non-essential electrical components and accessories. Understanding the causes, symptoms, and appropriate actions to take when this warning appears is crucial for maintaining your vehicle's electrical system and avoiding potential breakdowns.

The P0042 diagnostic trouble code indicates a problem with the heater control circuit for the heated oxygen sensor (HO2S) bank 1, sensor 3. This sensor plays a crucial role in monitoring the air/fuel mixture and emissions control. Let's explore this code in detail.

Bài viết liên quan

Autonomous Emergency Braking (AEB) technology has emerged as a game-changer in the realm of vehicle safety, holding the potential to dramatically reduce the occurrence and severity of collisions on our roads. By leveraging an intricate network of sensors and advanced algorithms, AEB systems can identify impending collisions and automatically engage the brakes, even in situations where the driver is unable to react in time. This article will provide an in-depth exploration of the inner workings of AEB, its numerous benefits, real-world performance data, integration with other advanced driver assistance systems (ADAS), regulatory requirements, and industry adoption trends. Furthermore, we will address the limitations and considerations associated with this life-saving technology.

Regenerative braking is an innovative energy recovery mechanism that slows down a moving vehicle by converting its kinetic energy into a form that can be either used immediately or stored until needed. This article will delve into the intricacies of regenerative braking systems, exploring how they work, their benefits, and their role in shaping the future of sustainable transportation. We will compare regenerative braking with conventional braking systems, discuss its integration with other vehicle systems, and examine its performance in various driving conditions. Furthermore, we will highlight the advancements in regenerative braking technology, its environmental impact, and the challenges and opportunities it presents.

Advanced Driver Assistance Systems (ADAS) have revolutionized the automotive industry by integrating sophisticated technologies into vehicles to enhance driver safety and comfort. These systems utilize a combination of sensors, cameras, radar, and software to perceive the environment around the vehicle and assist the driver in various driving tasks. One crucial aspect of ADAS is its integration with the vehicle's braking system, which enables features such as Autonomous Emergency Braking (AEB), Adaptive Cruise Control (ACC), and Electronic Stability Control (ESC).

Anti-lock Braking System (ABS) is a critical safety feature in modern vehicles that prevents wheel lockup during hard braking, allowing the driver to maintain steering control and avoid uncontrolled skidding.

In the world of automotive safety and performance, brake pads and rotors play a crucial role in ensuring that vehicles can stop effectively and reliably. However, traditional brake materials have limitations that can affect braking performance, durability, and overall safety. To address these challenges, researchers and manufacturers have been developing innovative materials for brake pads and rotors that offer improved performance, longer life spans, and enhanced safety features. This article will explore the latest advancements in brake pad and rotor materials, including advanced composites, innovative alloys, coatings, and surface treatments, as well as nanoparticle reinforcements and adaptive materials. We will also discuss the environmental considerations and future trends in brake material technology.

The automotive industry is undergoing a significant transformation, with electrification and brake-by-wire systems at the forefront of this change. These technologies are revolutionizing the way vehicles brake, enhancing safety, performance, and efficiency. In this article, we will explore the rise of electrification in the automotive industry, the emergence of brake-by-wire technology, and their combined impact on the future of automotive braking. We will delve into the workings of brake-by-wire systems, their advantages over traditional braking systems, and their crucial role in the era of electric and autonomous vehicles.

Modular and distributed brake systems represent a significant advancement in vehicle safety technology. These innovative braking solutions offer numerous benefits over traditional centralized braking systems, including improved fault tolerance, enhanced performance, and increased flexibility in vehicle design. By adopting modular and distributed brake systems, the automotive industry is poised to revolutionize the way vehicles handle braking and ensure a safer driving experience for everyone on the road.