Thermally driven chillers are revolutionizing the cooling industry by harnessing waste heat and renewable thermal energy to provide efficient and eco-friendly cooling solutions. These innovative chillers offer a sustainable alternative to traditional electric chillers, reducing energy consumption, operational costs, and environmental impact. As the demand for sustainable cooling grows, thermally driven chillers are poised to play a crucial role in shaping the future of the cooling industry.

Engine Derating: Optimizing Performance, Efficiency, and Longevity

Engine Derating: Optimizing Performance, Efficiency, and Longevity

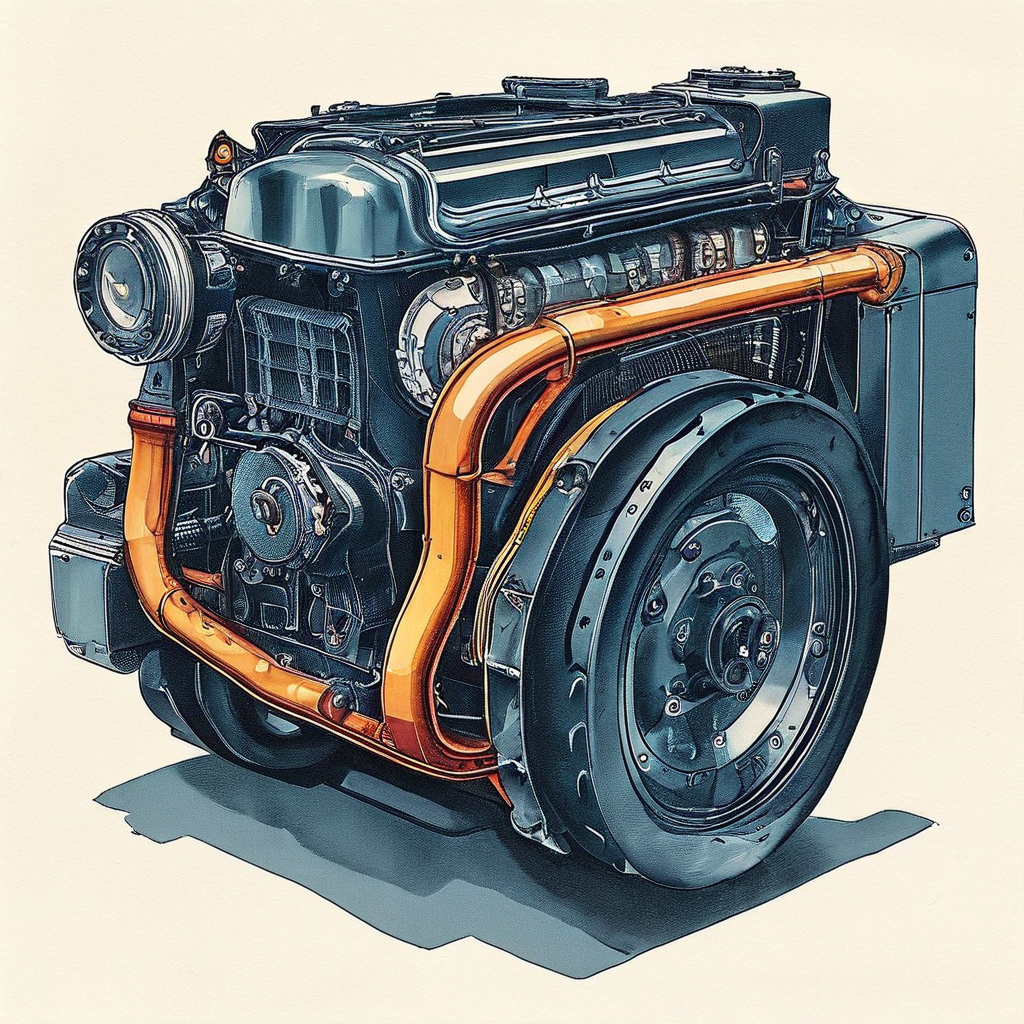

Engine derating is a strategic technique employed in the automotive industry to intentionally reduce an engine's output below its maximum rated capacity. This comprehensive article explores the intricacies of engine derating, delving into its causes, types, advantages, implementation, and applications within the automotive realm.

I. Introduction

Engine derating involves the intentional reduction of an engine's output power or thrust below its maximum rated capacity. This technique aims to prolong the engine's life, reduce wear and tear, improve fuel efficiency, and meet specific operational requirements. By adjusting various parameters, derating optimizes engine performance while minimizing its environmental impact and operational costs.

II. Causes and Reasons for Engine Derating

The decision to implement engine derating can stem from various factors, as outlined in the following table:

| Cause | Explanation |

|---|---|

| High ambient temperatures | As temperatures rise above the engine's designed operating conditions, its efficiency and output power decrease. Derating compensates for this loss by adjusting the engine's settings, ensuring optimal performance even in hot weather conditions. |

| High altitude operations | At higher altitudes, the lower air density can reduce an engine's ability to produce its rated power. Derating helps maintain the desired performance by accounting for the reduced air density. |

| Engine life extension | Running an engine at its maximum rated capacity can accelerate wear and tear on its components. Derating reduces stress on the engine, prolonging its service life and reducing maintenance costs. |

| Noise reduction | Derating can lower an engine's noise output, which is particularly important for vehicles operating in urban areas or noise-sensitive environments. |

| Emissions control | By lowering combustion temperatures and improving efficiency, derating can help reduce an engine's emissions, such as nitrogen oxides (NOx) and carbon dioxide (CO2), contributing to environmental sustainability. |

III. Types of Engine Derating

There are two main methods for achieving engine derating:

Derate levels

Assumed temperature

Derate levels

This method involves electronically limiting the engine's rated power output to a predetermined level below its maximum capacity. Multiple derate levels may be available, allowing for varying degrees of derating based on specific operational requirements.

Electronic thrust or power limitation: The engine's control system is programmed to restrict the maximum thrust or power output, effectively capping the engine's performance at a lower level.

Multiple derate levels: Some engines offer multiple derate levels, providing flexibility to choose the appropriate level of derating based on factors such as ambient temperature, altitude, or desired performance characteristics.

Assumed temperature

In this method, the engine's control system is instructed to assume a higher ambient temperature than the actual conditions. This causes the engine to reduce its output as if it were operating in hotter conditions, even though the real temperature is lower.

Simulating higher ambient conditions: By simulating higher ambient temperatures, the engine's control system adjusts various parameters, such as fuel flow and ignition timing, to reduce output and maintain optimal performance.

Adjusting engine control system: The engine control system is recalibrated to respond as if the ambient temperature is higher than the actual conditions, triggering derating protocols and adjusting the engine's operation accordingly.

IV. Advantages of Engine Derating

Engine derating offers numerous advantages, including:

Extended engine life and reduced maintenance costs

Improved fuel efficiency

Lower emissions

Noise reduction

Increased operational flexibility

Let's explore each of these advantages in detail:

Extended engine life and reduced maintenance costs

By reducing stress on the engine components, derating can significantly extend the engine's service life. This translates into lower maintenance costs and fewer overhauls or replacements, resulting in substantial cost savings over the engine's lifetime.

Improved fuel efficiency

Derating can improve fuel efficiency, especially during takeoff and climb phases when engines typically operate at higher power settings. By reducing the engine's output, less fuel is consumed, leading to improved fuel economy and lower operating costs.

Lower emissions

Derating reduces combustion temperatures and improves overall engine efficiency, resulting in lower emissions of harmful pollutants such as nitrogen oxides (NOx) and carbon dioxide (CO2). This contributes to environmental sustainability and compliance with emissions regulations.

Noise reduction

By limiting the engine's output, derating can effectively reduce noise levels, making vehicles more suitable for urban environments or noise-sensitive applications.

Increased operational flexibility

In some cases, derating can allow for higher takeoff weights or shorter runway lengths, providing increased operational flexibility and enabling vehicles to operate in a wider range of conditions.

V. Disadvantages and Risks of Engine Derating

While engine derating offers several benefits, it is essential to consider the potential disadvantages and risks associated with this technique:

| Disadvantage/Risk | Explanation |

|---|---|

| Reduced performance and climb rates | Derating can result in reduced performance and slower climb rates, which may impact acceleration and overall vehicle dynamics. |

| Risk of miscalculations or incorrect settings | Improper implementation of derating or incorrect settings can lead to insufficient power output, potentially compromising safety and performance. |

| Potential conflicts with regulatory requirements | In certain applications or regions, derating practices may conflict with regulatory requirements or vehicle limitations, necessitating careful consideration and compliance. |

| Complexity in performance calculations and crew training | Implementing derating requires precise performance calculations and thorough crew training to ensure proper understanding and execution of derating procedures. |

VI. Technical Implementation and Mechanisms

The technical implementation of engine derating involves adjustments to various components and systems within the engine, including:

Engine control system adjustments

Fuel management strategies

Compressor and turbine settings

Operating envelope modifications

Engine control system adjustments

The engine's control system governs various aspects of engine operation, such as fuel delivery, ignition timing, and air/fuel mixture. Derating involves adjustments to these control parameters to achieve the desired power or thrust reduction.

Fuel management strategies

Derating may involve limiting fuel flow or adjusting fuel injection parameters to reduce the amount of fuel supplied to the engine, thereby reducing its output power.

Compressor and turbine settings

In turbocharged or supercharged engines, derating can be achieved by adjusting the compressor and turbine settings to limit the amount of air supplied to the engine, effectively reducing its output.

Operating envelope modifications

The engine's operating envelope, which defines the range of conditions under which it can safely operate, may be modified to accommodate derating protocols, ensuring optimal performance within the desired parameters.

VII. Applications of Engine Derating

Engine derating finds applications across various industries, including:

Aviation

Commercial aviation

Military aviation

Power generation

Marine propulsion

Automotive industry

Aviation

Commercial aviation

Derating is commonly employed in commercial aviation to reduce engine wear, noise, and emissions during takeoff and climb phases, while also extending engine life and improving fuel efficiency.

Military aviation

Military aircraft often utilize derating to optimize engine performance for specific mission requirements, such as high-altitude operations or extended loiter times.

Power generation

Derating can help optimize the performance and efficiency of engines used in power plants, particularly in hot or high-altitude environments, reducing emissions and extending maintenance intervals.

Marine propulsion

Ship engines may be derated to improve fuel efficiency, reduce emissions, and extend maintenance intervals, contributing to cost savings and environmental sustainability.

Automotive industry

Some high-performance vehicles may use derating to improve engine longevity and meet emissions standards, while still providing ample power for everyday driving conditions.

VIII. Best Practices, Guidelines, and Regulatory Requirements

To ensure the safe and effective implementation of engine derating, manufacturers and operators typically follow best practices and guidelines, including:

Crew training and cross-checking procedures

Adherence to manufacturer guidelines

Compliance with aviation and environmental regulations

Crew training and cross-checking procedures

Proper crew training and adherence to cross-checking procedures are essential for the safe and effective implementation of engine derating, ensuring that all settings and calculations are accurate.

Adherence to manufacturer guidelines

Engine manufacturers provide specific guidelines and recommendations for derating practices, which must be followed to maintain warranty coverage and ensure optimal performance.

Compliance with aviation and environmental regulations

Regulatory bodies, such as aviation authorities and environmental agencies, often provide guidelines or requirements for engine derating practices to ensure safety and compliance with emissions standards.

IX. Future Trends and Advancements

As environmental concerns and sustainability efforts continue to gain importance, the development of more advanced engine derating technologies and strategies is likely to continue. Some potential future trends and advancements include:

Development of advanced derating technologies

Integration with emission reduction strategies

Improvements in engine control systems and fuel management

Development of advanced derating technologies

More advanced engine derating technologies and strategies are being developed, enabling more precise and efficient derating implementation.

Integration with emission reduction strategies

Derating may be integrated with other emission reduction technologies, such as exhaust aftertreatment systems or alternative fuel sources, to further reduce the environmental impact of engines.

Improvements in engine control systems and fuel management

Advancements in engine control systems and fuel management techniques will likely enhance the capabilities and precision of derating methods, allowing for more granular control and optimization.

X. Conclusion

Engine derating is a valuable technique for optimizing engine performance, extending service life, and reducing environmental impact across various industries, including the automotive sector. By understanding the principles, advantages, and potential risks of derating, manufacturers and operators can effectively implement derating strategies to achieve their operational goals while maintaining safety and compliance.

As environmental concerns and sustainability efforts continue to shape the automotive industry, the adoption of derating and other emission reduction technologies will become increasingly important. By embracing these advancements and adhering to best practices, the automotive industry can pave the way for more efficient, environmentally friendly, and cost-effective engine solutions.

FAQs

What is the purpose of engine derating?

Engine derating aims to prolong engine life and reduce wear and tear. It optimizes performance by intentionally reducing an engine's output below its maximum rated capacity.

What are the main causes of engine derating?

High ambient temperatures and high altitude operations are major causes of engine derating. Other reasons include engine life extension, noise reduction, and emissions control.

How is engine derating typically achieved?

Engine derating can be achieved through electronic thrust or power limitation, adjusting assumed ambient temperature, cutting out turbochargers or cylinders, and various tuning methods.

What are the advantages of engine derating?

Key advantages include extended engine life, reduced maintenance costs, improved fuel efficiency, lower emissions, noise reduction, and increased operational flexibility.

Are there any disadvantages to engine derating?

Potential disadvantages include reduced performance and climb rates, risk of miscalculations or incorrect settings, conflicts with regulatory requirements, and complexity in performance calculations and crew training.

How is engine derating implemented technically?

Technical implementation involves adjustments to the engine control system, fuel management strategies, compressor and turbine settings, and operating envelope modifications.

In which industries is engine derating commonly used?

Engine derating finds applications in aviation (commercial and military), power generation, marine propulsion, and the automotive industry.

What are the best practices for engine derating?

Best practices include crew training, adherence to manufacturer guidelines, compliance with aviation and environmental regulations, and cross-checking procedures.

How does engine derating contribute to environmental sustainability?

By reducing combustion temperatures, improving efficiency, and lowering emissions, engine derating contributes to environmental sustainability and compliance with emissions regulations.

What are the future trends in engine derating?

Future trends include the development of advanced derating technologies, integration with emission reduction strategies, and improvements in engine control systems and fuel management.

Bình luận (0)

Bài viết đề xuất

Transmission fluid plays a crucial role in the proper functioning of a vehicle's transmission system. It lubricates the moving parts, provides hydraulic pressure for gear shifting, and helps dissipate heat generated by the transmission.

The oil light is an important indicator on a vehicle's dashboard that alerts the driver about potential issues with the engine's lubrication system. It is designed to illuminate when the oil pressure drops below a certain level, which can be caused by various factors.

The compressor is the heart of an air conditioning system that pumps refrigerant through the coils to remove heat and humidity from indoor air. In a properly functioning AC unit, the compressor should run in cycles of around 15-20 minutes, 2-3 times per hour. This allows the system to maintain the desired temperature set on the thermostat.

Bài viết liên quan

Rebuilding an engine is a significant undertaking that requires careful consideration of various factors, including costs, processes, and potential issues. The 5.3 Vortec engine, a popular V8 powerplant produced by General Motors, is no exception.

Opening the oil cap when the engine is hot can be a risky endeavor, but understanding the potential dangers and following proper procedures can ensure your safety and protect your vehicle's longevity.

The Ford 289 and 302 cubic inch V8 engines have captivated automotive enthusiasts for decades, igniting debates and fueling passions among muscle car aficionados and hot rodders alike.

Cummins Inc., a multinational corporation headquartered in Columbus, Indiana, has been at the forefront of engine technology since its inception in 1919. Founded by Clessie Cummins and William Glanton Irwin, the company has evolved into a global powerhouse, offering a comprehensive range of innovative engine solutions for various applications

The Honda 1.5-liter turbocharged engine, introduced in 2016, has garnered attention for its impressive power and fuel efficiency. However, this engine has also been plagued by recurring issues that have raised concerns among owners and mechanics.

Carbon buildup on pistons is a common issue that can significantly impact engine performance and longevity if left unchecked. This buildup refers to the accumulation of carbon deposits on the piston tops, ring lands, and cylinder walls, resulting from incomplete combustion of fuel and burned oil.

Engine derating is a strategic technique employed in the automotive industry to intentionally reduce an engine's output below its maximum rated capacity.

Maintaining your vehicle's engine is crucial for ensuring optimal performance, fuel efficiency, and longevity. One component that plays a vital role in this process is the intake manifold, responsible for distributing the air-fuel mixture to the cylinders.

Rebuilding an engine is a complex and labor-intensive task that requires a combination of mechanical skills, specialized tools, and meticulous attention to detail. While it is certainly a challenging endeavor, it is not an impossible feat for an experienced DIY enthusiast with the right knowledge and resources.

Maintaining a vehicle's engine is crucial for ensuring its longevity and performance. However, even with regular maintenance, issues like a cracked engine block can arise, posing a significant threat to the engine's integrity.