Hybrid vehicles combine an internal combustion engine with an electric motor and battery pack to improve fuel efficiency and reduce emissions. As these systems become more prevalent, issues can arise that trigger a "Hybrid System Malfunction" warning

How to Fix Lifters Ticking: Effective Solutions for Noisy Valve Lifters

How to Fix Lifters Ticking: Effective Solutions for Noisy Valve Lifters

Introduction

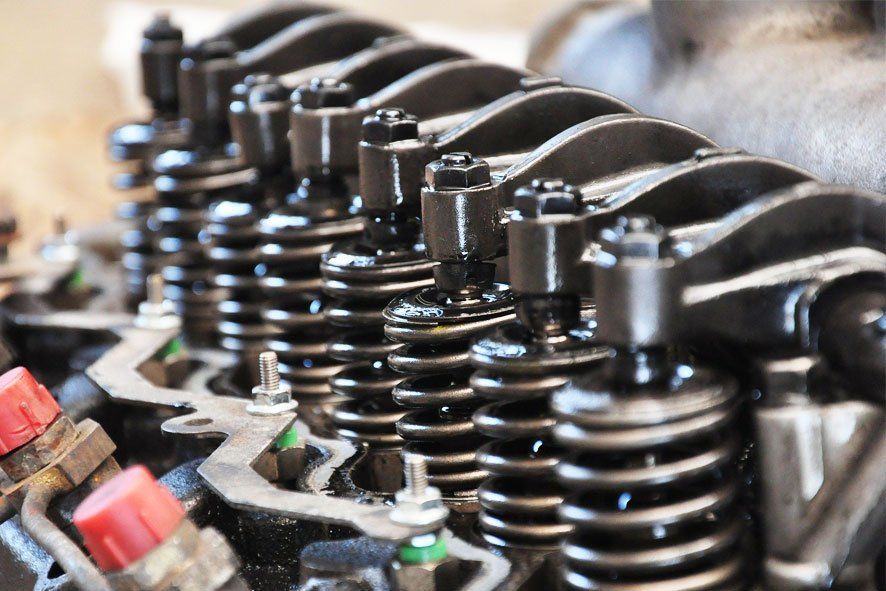

Lifter ticking is a common issue that can affect various types of internal combustion engines, particularly those found in automobiles. This distinct noise can be a symptom of underlying problems within the engine's valve train system, which is responsible for controlling the opening and closing of the intake and exhaust valves.

In this article, I'll share my expertise and walk you through the process of diagnosing and fixing lifter ticking. We'll explore the common causes, diagnostic techniques, repair procedures, preventive measures, and cost considerations. Whether you're a DIY enthusiast or simply want to understand the issue better, this guide will provide you with valuable insights and practical solutions.

Understanding the Causes of Lifter Ticking

Before we dive into the repair process, it's essential to understand the underlying causes of lifter ticking. This noise can stem from various issues within the valve train system, and identifying the root cause is crucial for effective troubleshooting.

Here are some common causes of lifter ticking:

| Cause | Description |

|---|---|

| Low Oil Level or Low Oil Pressure | Insufficient lubrication due to low oil levels or low oil pressure can cause increased friction and wear on the hydraulic lifters, leading to a ticking noise. |

| Faulty Hydraulic Lifters | Internal issues like a malfunctioning check valve or a worn-out piston can prevent the lifter from maintaining proper valve lash, resulting in ticking. |

| Camshaft Lobe Wear | As the camshaft lobes wear down, the lifters may fail to accurately follow the cam profile, leading to valve timing issues and ticking noises. |

| Bent Pushrods | A bent pushrod in the valve train can disrupt the motion transfer from the camshaft to the rocker arms, causing irregular valve movement and ticking. |

| Misaligned Valve Train Components | Improper alignment of parts like pushrods or rocker arms can create uneven stress on the lifters, causing damage and noise. |

Diagnosing the Issue

Before attempting any repairs, it's crucial to accurately diagnose the source of the lifter ticking. Here are some diagnostic steps I typically follow:

Locate the Ticking Noise

Check for Engine Misfires

Inspect the Valve Train

Repair Procedures

Depending on the diagnosis, various repair procedures may be necessary to address lifter ticking. Here are some common approaches:

| Repair Procedure | Description |

|---|---|

| Oil Change and Additive Treatment | If the ticking is caused by low oil level or dirty oil, perform an oil change and consider using a high-quality engine oil additive to quiet the lifters temporarily. |

| Lifter Replacement | If a lifter is found to be faulty, it needs to be replaced. This typically involves removing the cylinder head(s), intake and exhaust manifolds, and potentially other components to access the lifters. |

| Valve Adjustment | If the ticking is due to improper valve lash, adjust the valves according to the manufacturer's specifications. |

| Pushrod or Rocker Arm Replacement | If a pushrod is bent or a rocker arm is damaged or misaligned, replace the affected components. |

| Camshaft Replacement | In cases of severe camshaft lobe wear, the camshaft may need to be replaced, which is a more extensive repair. |

Prevention and Maintenance

While repairs are sometimes necessary, prevention is always the best approach when it comes to lifter ticking. Here are some tips to help maintain your engine's valve train and avoid costly repairs:

Regular Oil Changes

Use High-Quality Oil

Avoid Aggressive Driving

Periodic Inspections

Cost Considerations

The cost of repairing lifter ticking can vary significantly depending on the extent of the damage and the specific repair required. According to the search results:

Replacing a single lifter can cost between $1,000 and $2,500, including labor and parts.

If multiple lifters need replacement or if additional components like the camshaft or cylinder head(s) require repair or replacement, the cost can increase substantially.

Performing the repair yourself can significantly reduce the cost, but it requires specialized tools and mechanical expertise.

It's important to address lifter ticking promptly to prevent further damage and more expensive repairs down the line. Regular maintenance and proper driving habits can also help extend the lifespan of the valve train components.

Conclusion

Lifter ticking is a common issue that should not be ignored, as it can indicate underlying problems with the valve train system. By understanding the causes, properly diagnosing the issue, and following the appropriate repair procedures, you can effectively address this problem and ensure the smooth operation of your engine.

Remember, prevention is key. Adhering to regular maintenance schedules, using high-quality engine oil, and adopting responsible driving habits can go a long way in minimizing the risk of lifter ticking and other valve train-related issues.

If you're unsure about tackling this repair yourself, don't hesitate to seek the assistance of a professional mechanic. Their expertise and specialized tools can ensure the job is done correctly, potentially saving you time, money, and frustration in the long run.

FAQs

What is the most common cause of lifter ticking?

The most common cause is low oil level or low oil pressure, which leads to insufficient lubrication of the hydraulic lifters.

Can lifter ticking be fixed temporarily?

Yes, using a high-quality engine oil additive can sometimes quiet lifter ticking temporarily, but it does not address the underlying issue.

How do you locate the source of lifter ticking?

Use a mechanic's stethoscope or long screwdriver to pinpoint which area of the engine the ticking noise is coming from.

What happens if lifter ticking is ignored?

Ignoring lifter ticking can lead to more severe engine damage like camshaft lobe wear, bent pushrods, or broken rocker arms.

Is it difficult to replace hydraulic lifters?

Replacing hydraulic lifters requires extensive disassembly like removing cylinder heads, which makes it a complex job for DIYers.

Can bad spark plugs cause lifter ticking?

No, faulty spark plugs do not directly cause lifter ticking. The ticking is specifically related to issues in the valve train.

How often should you change engine oil to prevent lifter ticking?

Follow the manufacturer's recommended oil change intervals, but more frequent changes with high-quality oil can help prevent lifter issues.

Do all engines use hydraulic lifters?

No, some engines use solid or mechanical lifters instead of hydraulic lifters. Ticking in those engines indicates excessive valve lash.

Is lifter ticking louder when the engine is cold?

Yes, lifter ticking is often more pronounced when the engine is cold and the oil has not fully circulated and lubricated the lifters yet.

Can lifter ticking cause check engine lights?

Severe lifter ticking that impacts valve timing can potentially trigger the check engine light by causing misfires.

Bình luận (0)

Bài viết đề xuất

A transmission leak can be a serious issue that, if left unaddressed, can lead to costly repairs or even complete transmission failure. The transmission is a vital component of your vehicle, responsible for transferring power from the engine to the wheels, allowing you to shift gears smoothly.

The rack and pinion system is a critical component of a vehicle's steering mechanism, responsible for converting the rotational motion of the steering wheel into linear motion, allowing the wheels to turn left or right.

Modular and distributed brake systems represent a significant advancement in vehicle safety technology. These innovative braking solutions offer numerous benefits over traditional centralized braking systems, including improved fault tolerance, enhanced performance, and increased flexibility in vehicle design. By adopting modular and distributed brake systems, the automotive industry is poised to revolutionize the way vehicles handle braking and ensure a safer driving experience for everyone on the road.

Bài viết liên quan

Engines can become locked or seized due to various reasons, such as lack of lubrication, rust buildup, or prolonged inactivity. A seized engine can be a frustrating and potentially costly issue, but in some cases, it may be possible to unlock and revive the engine without the need for a complete overhaul or replacement.

Spark plugs are small yet crucial components in gasoline-powered internal combustion engines. They play a vital role in the engine's ignition system, responsible for igniting the air-fuel mixture within the combustion chamber

Spark plugs play a crucial role in the ignition system of gasoline engines. They are responsible for providing the spark that ignites the air-fuel mixture in the combustion chamber, allowing the engine to run.

Spark plugs are a crucial component in gasoline-powered internal combustion engines, responsible for igniting the air-fuel mixture and enabling the combustion process.

Oil leaks are a common issue faced by vehicle owners, occurring when engine oil seeps out from various components of the vehicle's engine. While a small amount of oil seepage is considered normal, excessive leakage can lead to significant problems.

The LS engine family, produced by General Motors, has been widely used in various vehicles since the late 1990s. Proper installation and torque specifications are crucial for ensuring the longevity and optimal performance of these engines.

Intake manifolds are a crucial component of an engine's air intake system. They are responsible for distributing the air/fuel mixture evenly to each cylinder for combustion.

The LS engine family from General Motors has been widely used in various vehicles, from performance cars to trucks, since its introduction in the late 1990s.

Lifter ticking is a common issue that can affect various types of internal combustion engines, particularly those found in automobiles.

The 5.3L Vortec engine is a popular V8 engine produced by General Motors (GM) and widely used in various GM trucks and SUVs. It has been a staple in vehicles such as the Chevrolet Silverado, GMC Sierra, Chevrolet Tahoe, and GMC Yukon models, among others.