Maintaining a comfortable cabin temperature is essential for an enjoyable driving experience. Climate control systems have evolved significantly, offering various options to cater to different preferences and needs.

How to Rebuild an Automatic Transmission Step-by-Step: A Comprehensive Guide

How to Rebuild an Automatic Transmission Step-by-Step: A Comprehensive Guide

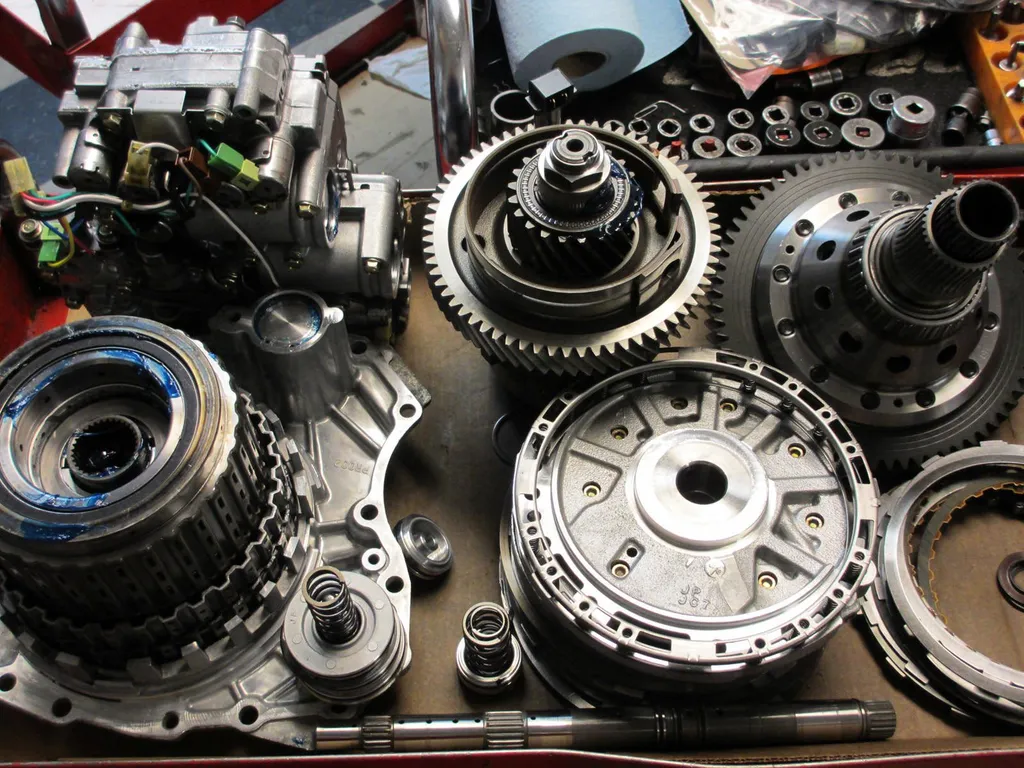

An automatic transmission is a complex system that transfers power from the engine to the wheels in an automobile. Over time, the components within the transmission can wear down, leading to various issues such as slipping gears, delayed shifts, or complete transmission failure. Rebuilding an automatic transmission involves disassembling the entire unit, inspecting and replacing worn or damaged parts, and reassembling it with new components and fluids. This process can be a cost-effective alternative to purchasing a new transmission, especially for older vehicles or those with high mileage.

Understanding Automatic Transmission Woes

Before we embark on the rebuild process, it's crucial to understand the common issues that can plague these complex machines. Trust me, I've seen my fair share of transmission troubles over the years, and they can be a real headache if not addressed properly.

| Common Automatic Transmission Problems |

|---|

| Low Transmission Fluid Level |

| Contaminated Fluid |

| Worn Clutch Packs and Bands |

| Faulty Solenoids and Sensors |

| Damaged Torque Converter |

Let's dive a little deeper into each of these problems:

Low Transmission Fluid Level: This is one of the most common culprits behind transmission issues. A low fluid level can lead to a variety of problems, such as slipping gears, overheating, and premature wear. The causes can range from leaks and faulty seals to good old-fashioned neglect.

Contaminated Fluid: Over time, transmission fluid can become contaminated with debris and metal shavings, which can wreak havoc on the internal components. Imagine trying to lubricate your transmission with a gritty, abrasive fluid – not a pretty picture!

Worn Clutch Packs and Bands: The clutch packs and bands are the unsung heroes of your transmission, responsible for engaging and disengaging gears. As they wear out, you might experience slipping, rough shifting, or even complete gear failure. It's like trying to shift gears with worn-out clutches in a manual transmission – not a smooth ride.

Faulty Solenoids and Sensors: Automatic transmissions rely on a complex network of solenoids and sensors to control fluid flow and gear shifts. When these components malfunction, you might experience erratic shifting or, in some cases, complete transmission failure. It's like having a faulty traffic light directing the flow of your transmission's "traffic."

Damaged Torque Converter: Last but not least, we have the torque converter – the crucial component that transfers power from the engine to the transmission. Damage or wear to this component can result in shuddering, slipping, or poor acceleration. Imagine trying to drive with a slipping clutch in a manual transmission – not a fun experience.

Diagnosing Transmission Issues

Before we dive into the rebuild process, it's essential to diagnose the issue correctly. Here's a step-by-step approach to help you identify the root cause of your transmission woes:

Check Transmission Fluid Level and Condition

Listen for Unusual Noises

Observe Shifting Behavior

Check for Leaks

Scan for Diagnostic Trouble Codes

Let's explore each of these steps in more detail:

Check Transmission Fluid Level and Condition: Start by checking the transmission fluid level with the engine running and the transmission in park. The fluid should be at the proper level and have a bright red color, free of debris or metal shavings. If the fluid looks or smells burnt, it's a clear sign of trouble.

Listen for Unusual Noises: Whining, grinding, or clunking noises can be telltale signs of worn bearings, gears, or other internal components. Trust your ears – they can often detect issues before they become catastrophic.

Observe Shifting Behavior: Pay close attention to how your transmission shifts gears. Any slipping, rough shifting, or delayed engagement can indicate a problem that needs to be addressed.

Check for Leaks: Inspect the transmission case, cooler lines, and pan for any signs of fluid leaks. Even a small leak can lead to low fluid levels and potential damage over time.

Scan for Diagnostic Trouble Codes: Modern vehicles are equipped with OBD-II diagnostic systems that can provide valuable insights into transmission issues. Use a scanner to check for any transmission-related trouble codes, which can help pinpoint the problem.

The Transmission Rebuild Process

Now, let's get to the heart of the matter – the actual rebuild process. Grab your tools and get ready for some hands-on action!

| Transmission Rebuild Process |

|---|

| Removal and Disassembly |

| Cleaning and Inspection |

| Reassembly |

| Fluid Replacement |

| Testing and Adjustment |

Removal and Disassembly: The first step is to remove the transmission from the vehicle. This can be a challenging task, so make sure you have the proper tools and equipment, such as a transmission jack and lift. Once removed, carefully disassemble the transmission, keeping all components organized and labeled for reassembly.

Cleaning and Inspection: With the transmission disassembled, it's time for a thorough cleaning and inspection. Use appropriate solvents and brushes to remove any grime, debris, or contaminants from all components. Carefully inspect each part for wear, damage, or excessive scoring. Replace any worn or damaged parts with high-quality replacements.

Reassembly: Now comes the fun part – putting the puzzle back together! Follow the manufacturer's instructions and torque specifications to the letter as you reassemble the transmission. Use new gaskets, seals, and clutch packs as needed to ensure a proper seal and smooth operation.

Fluid Replacement: Once the transmission is reassembled, it's time to replace the fluid and filter. Use only high-quality, manufacturer-recommended transmission fluid to ensure proper lubrication and performance.

Testing and Adjustment: With the transmission reinstalled in the vehicle, it's time for the final step – testing and adjustment. Follow the manufacturer's guidelines for any necessary adjustments, such as band adjustments or linkage adjustments. Then, take the vehicle for a thorough road test to ensure proper operation and smooth shifting.

Tips and Precautions

Throughout the rebuild process, there are a few tips and precautions I'd like to share:

Use high-quality transmission parts and fluids from reputable manufacturers. Cutting corners can lead to premature failure and costly repairs down the line.

Follow all safety precautions when working with heavy components and tools. Transmission components can be heavy and awkward to handle, so take the necessary precautions to avoid injury.

If you lack experience or confidence in your abilities, don't hesitate to consult repair manuals or seek professional assistance. A botched transmission rebuild can be a costly mistake.

Keep your work area clean and organized to prevent contamination. Even a small speck of debris can cause significant damage to the internal components of your transmission.

| Safety Precautions |

|---|

| Wear Protective Gear (Gloves, Safety Glasses, etc.) |

| Use Proper Lifting Techniques |

| Follow Manufacturer's Instructions Carefully |

| Keep Work Area Clean and Organized |

Preventing Future Issues

Once you've successfully rebuilt your transmission, it's essential to take steps to prevent future issues. Here are a few recommendations:

Regular Maintenance: Follow the manufacturer's recommended maintenance schedule for transmission fluid changes and inspections. Regular maintenance can go a long way in extending the life of your transmission.

Proper Driving Habits: Avoid aggressive driving, excessive towing, and abrupt gear changes, which can strain the transmission and lead to premature wear. Treat your transmission with care, and it will reward you with years of reliable service.

Address Issues Promptly: If you notice any signs of transmission trouble, such as slipping, rough shifting, or unusual noises, have it inspected and repaired promptly. Ignoring these issues can lead to more significant and costly problems down the road.

| Preventive Measures |

|---|

| Regular Maintenance |

| Proper Driving Habits |

| Address Issues Promptly |

Cost Considerations

Now, let's address the elephant in the room – the cost of rebuilding an automatic transmission. The truth is, the cost can vary significantly depending on several factors, such as the make and model of your vehicle, the extent of damage, and labor costs in your area.

| Cost Factors |

|---|

| Vehicle Make and Model |

| Extent of Damage |

| Labor Costs in Your Area |

On average, you can expect to pay between $1,500 and $4,000 for a professional transmission rebuild, including parts and labor. If you choose to tackle the rebuild yourself, you can save on labor costs, but you'll need to invest in specialized tools, parts, and fluids.

Rebuilding a transmission is no small feat, but for those with the skills, patience, and determination, it can be a rewarding and cost-effective solution to extend the life of your vehicle.

Final Thoughts

Rebuilding an automatic transmission is a challenging but achievable task for those with the right knowledge and tools. By following the steps outlined in this guide, diagnosing the issue correctly, and taking the necessary precautions, you can breathe new life into your transmission and enjoy many more miles of smooth, reliable performance.

Remember, prevention is key. Regular maintenance, proper driving habits, and addressing issues promptly can go a long way in preventing transmission problems in the first place.

So, fellow automotive enthusiasts, roll up your sleeves, grab your tools, and get ready to tackle that transmission rebuild with confidence. And if you ever find yourself in over your head, don't hesitate to seek professional assistance. Happy wrenching!

FAQs

What tools are essential for rebuilding an automatic transmission?

You will need specialized tools like a transmission jack, bearing pullers, seal installers, and torque wrenches. Having the correct tools is crucial for a successful rebuild.

How does the rebuild process differ for different types of automatic transmissions?

While the general process is similar, the specific steps and components may vary depending on the transmission type, such as conventional hydraulic, continuously variable (CVT), or dual-clutch transmissions.

How long does it typically take to complete a transmission rebuild?

The duration can vary, but a professional transmission rebuild can take anywhere from 8 to 16 hours, depending on the complexity and the technician's experience.

What is the recommended way to dispose of used transmission fluid?

Used transmission fluid should be disposed of responsibly at authorized recycling centers or hazardous waste facilities, as it can be harmful to the environment if not handled properly.

Can a transmission rebuild restore the transmission to like-new condition?

Yes, a professional transmission rebuild, when done correctly with high-quality parts and following manufacturer specifications, can restore the transmission to like-new condition and performance.

Is it necessary to replace the torque converter during a transmission rebuild?

In most cases, it is recommended to replace the torque converter during a transmission rebuild, as it is a crucial component that can wear out and affect the overall performance of the rebuilt transmission.

What are the signs that a transmission needs to be rebuilt?

Common signs include slipping gears, rough shifting, delayed engagement, transmission fluid leaks, and unusual noises or vibrations coming from the transmission.

Can a transmission rebuild improve fuel efficiency?

Yes, a properly rebuilt transmission can improve fuel efficiency by ensuring smooth and efficient gear shifts, reducing strain on the engine, and eliminating any internal leaks or friction.

Is it possible to rebuild a transmission without removing it from the vehicle?

In most cases, it is necessary to remove the transmission from the vehicle to perform a complete rebuild, as it requires disassembling and inspecting all internal components.

How long does a rebuilt transmission typically last?

With proper maintenance and driving habits, a professionally rebuilt transmission can last anywhere from 50,000 to 150,000 miles or more, depending on the quality of the rebuild and the vehicle's usage.

Bình luận (0)

Bài viết đề xuất

The P003A diagnostic trouble code signals an issue with your vehicle's turbocharger or supercharger boost control system. Specifically, it indicates that the position of the "A" boost control arm, responsible for regulating the turbocharger vanes or geometry, has exceeded the allowable learning limit set by the engine control module (ECM). This comprehensive guide unravels the intricacies of this code, exploring its symptoms, causes, diagnosis, and repair procedures, while shedding light on the intricate world of boost pressure regulation and vane position control.

Pipes and tubing are essential components in various industries, including plumbing, construction, manufacturing, and transportation. They are responsible for carrying liquids, gases, and other materials from one point to another.

When it comes to maintaining the braking system of your vehicle, understanding the appropriate brake line size is crucial. Brake lines play a vital role in delivering the hydraulic pressure from the master cylinder to the brake calipers, ensuring optimal braking performance and safety.

Bài viết liên quan

The Transmission Control Module (TCM) is an essential component in modern vehicles equipped with automatic transmissions. As automotive technology has advanced, transmissions have become increasingly complex, necessitating the integration of electronic controls to manage their operation effectively.

Transmission lines are responsible for carrying transmission fluid to and from the transmission cooler, which is typically integrated into the radiator. Over time, the connections between these lines and the radiator fittings can develop leaks, leading to transmission fluid loss and potential transmission damage if left unaddressed.

Adjusting the shift linkage is a crucial process in ensuring smooth and precise gear shifting in both manual and automatic transmissions. The shift linkage is a system of cables, rods, and levers that connect the gear shift lever to the transmission.