The coolant reservoir plays a crucial role in maintaining the optimal temperature and performance of your vehicle's engine. It works in conjunction with other cooling system components, such as the radiator, water pump, and thermostat, to circulate coolant and dissipate heat. When a coolant reservoir develops cracks, it can compromise the entire cooling system, leading to engine overheating and severe damage if left unchecked.

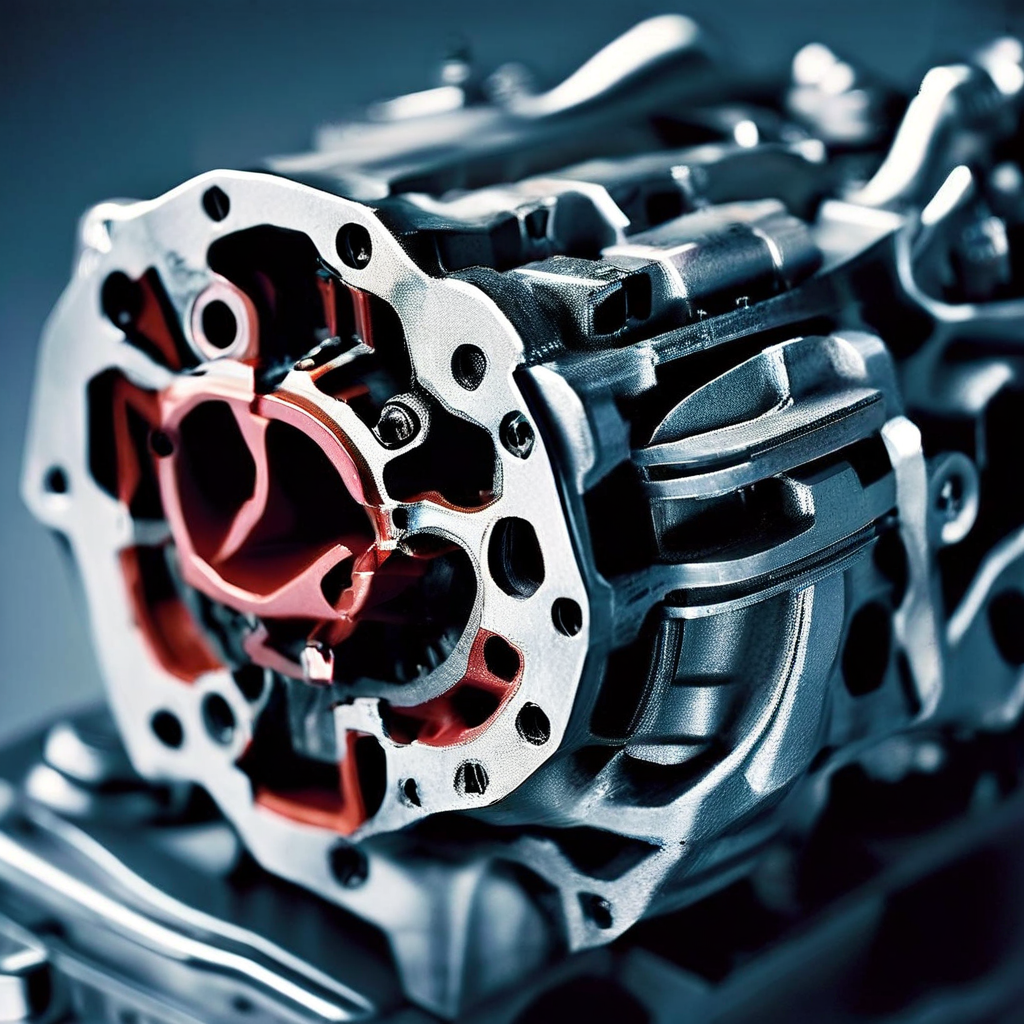

The Cylinder Head: Unraveling the Beating Heart of Your Engine

The Cylinder Head: Unraveling the Beating Heart of Your Engine

The cylinder head is an intricate and indispensable component that sits atop the engine block, orchestrating the intricate dance of combustion that propels your vehicle forward. This article delves into the intricacies of this vital engine part, exploring its definition, purpose, components, types, materials, functions, common issues, maintenance requirements, and the latest advancements in cylinder head technology.

Introduction to the Cylinder Head

The cylinder head is a meticulously engineered metal casting that seals the top of the engine cylinders, forming the combustion chamber where the air-fuel mixture ignites and burns. Its primary function is to regulate the precise flow of air, fuel, and exhaust gases in and out of the cylinders, while also providing a secure mounting point for crucial components such as valves, spark plugs, and fuel injectors.

| Component | Purpose |

|---|---|

| Combustion Chamber | The space where the air-fuel mixture is compressed and ignited, generating the power that drives the engine. |

| Intake and Exhaust Valves | Control the flow of the air-fuel mixture into the combustion chamber and the exhaust gases out of it, respectively. |

| Intake and Exhaust Ports | Allow the air-fuel mixture to enter the combustion chamber and the exhaust gases to exit. |

| Spark Plugs/Fuel Injectors | Provide the ignition source or fuel injection for the combustion process. |

| Valve Guides and Seats | Support and seal the valves, ensuring proper operation and preventing leaks. |

| Cooling Passages | Allow coolant to circulate and dissipate heat from the combustion process. |

The cylinder head is bolted to the top of the engine block, with a head gasket in between to ensure a tight seal. It works in tandem with the pistons, crankshaft, and other components to convert the energy from the combustion process into mechanical power that propels the vehicle.

Main Components and Parts

A typical cylinder head is a symphony of intricate components that work together to facilitate the engine's operation.

Combustion Chamber

The combustion chamber is the heart of the cylinder head, where the air-fuel mixture is compressed and ignited, generating the power that drives the engine. Its design and geometry play a crucial role in optimizing the combustion process and maximizing engine efficiency.

Intake and Exhaust Valves

The intake and exhaust valves are the gatekeepers that control the flow of the air-fuel mixture into the combustion chamber and the exhaust gases out of it, respectively. These valves are operated by the camshaft(s) through a valve train mechanism, ensuring precise timing and coordination with the engine's cycle.

Intake and Exhaust Ports

The intake and exhaust ports are the pathways that allow the air-fuel mixture to enter the combustion chamber and the exhaust gases to exit, respectively. The design and shape of these ports significantly impact the engine's airflow characteristics and, consequently, its performance and efficiency.

Spark Plugs and Fuel Injectors

Spark plugs (in gasoline engines) and fuel injectors (in diesel engines) are mounted in the cylinder head and play a crucial role in the combustion process. Spark plugs provide the ignition source for the air-fuel mixture, while fuel injectors precisely deliver the fuel into the combustion chamber.

Valve Guides and Seats

Valve guides and seats are the unsung heroes within the cylinder head that support and seal the valves, ensuring proper operation and preventing leaks. These parts are subject to wear over time and may require periodic maintenance or replacement.

Cooling Passages

The cylinder head features an intricate network of cooling passages that allow coolant to circulate and dissipate heat from the combustion process. Proper cooling is essential to prevent overheating and potential engine damage.

Different Types of Cylinder Heads

Cylinder heads can be classified based on their design and the arrangement of their components, each offering unique advantages and trade-offs.

| Design Type | Description |

|---|---|

| Flathead | An older configuration where the valves are located in the engine block, rather than the cylinder head. Simple construction but poor performance. |

| Overhead Valve (OHV) | Also known as the "I-head" design, the valves are located in the cylinder head, above the combustion chamber. Improved airflow and performance. |

| Overhead Cam (OHC) | The camshaft(s) are located within the cylinder head, directly actuating the valves without the need for pushrods. Further enhanced airflow and efficiency. |

Materials Used and Their Advantages

Cylinder heads are typically manufactured using either cast iron or aluminum alloy, each material offering distinct advantages and trade-offs.

Cast Iron:

Durable and cost-effective

Excellent wear resistance

Can withstand high temperatures and pressures

Heavier and lower heat dissipation capabilities

Aluminum Alloy:

Lighter in weight

Superior heat dissipation properties

Improved engine cooling and potentially higher performance

More expensive and susceptible to warpage at extreme temperatures

The choice of material for the cylinder head depends on various factors, including engine design, performance requirements, cost considerations, and the intended application.

Functions and Importance

Beyond housing the valves and combustion chamber, the cylinder head serves several critical functions that directly impact the engine's overall performance and efficiency.

Sealing the Combustion Chamber

One of the primary functions of the cylinder head is to seal the combustion chamber, in conjunction with the head gasket. This seal is crucial for maintaining the high pressures and temperatures required for efficient combustion, preventing leaks and ensuring optimal engine operation.

Cooling the Engine

The intricate network of cooling passages within the cylinder head plays a vital role in dissipating heat generated during the combustion process. Proper heat dissipation is essential to prevent overheating, which can lead to engine damage and reduced performance.

Optimizing Airflow

The design of the intake and exhaust ports, as well as the valve arrangement, significantly impacts the engine's airflow characteristics. Optimized airflow is crucial for maximizing power output, fuel efficiency, and minimizing emissions.

Mounting Injectors and Spark Plugs

The cylinder head provides the mounting points for fuel injectors (in diesel engines) and spark plugs (in gasoline engines), which are essential components for the combustion process. Proper placement and integration of these components are critical for efficient and reliable engine operation.

The cylinder head's design and construction play a crucial role in determining an engine's power output, fuel efficiency, emissions, and overall performance. Manufacturers invest significant resources in optimizing cylinder head designs to meet specific performance and efficiency targets for their engines.

Common Issues and Maintenance

Like any engine component, cylinder heads can experience various issues over time, which can impact engine performance and potentially lead to costly repairs if left unaddressed.

| Issue | Description |

|---|---|

| Cracks | Caused by excessive heat, coolant leaks, or manufacturing defects. Can lead to compression loss, coolant leaks, and potential engine failure. |

| Warpage | Aluminum cylinder heads are susceptible to warpage due to extreme temperatures. Can cause head gasket failure, compression loss, and potential engine damage. |

| Valve and Seat Wear | Over time, the valves and their seats can wear down, leading to poor sealing, compression loss, and potential engine damage. |

Regular maintenance is crucial for ensuring the longevity and optimal performance of the cylinder head. This may include tasks such as:

Replacing the head gasket

Resurfacing the cylinder head to restore flatness

Inspecting and replacing worn valves and seats

Checking and adjusting valve lash (clearance)

In severe cases, a complete cylinder head replacement may be necessary to address significant damage or wear.

Latest Advancements and Future Trends

As engine technology continues to evolve, cylinder head designs are also advancing to meet stricter emissions regulations and performance demands.

Lightweight Materials:

Advanced aluminum alloys and composite materials

Further reduce weight and improve heat dissipation capabilities

Contribute to better fuel efficiency and performance

Variable Valve Timing:

Adjust the timing of the intake and exhaust valves dynamically

Optimize performance and efficiency across different operating conditions

Increasingly prevalent in modern engines

Integrated Exhaust Manifolds:

Cylinder head designs with integrated exhaust manifolds

Improve exhaust flow and reduce weight

Eliminate the need for separate manifold components

Additive Manufacturing:

3D printing and additive manufacturing techniques

Produce complex cylinder head designs with optimized internal geometries

Difficult or impossible to achieve through traditional manufacturing methods

As the automotive industry continues to push for higher efficiency, lower emissions, and better performance, the cylinder head will remain a critical area of research and development, driving innovation in engine technology.

Conclusion

The cylinder head is a vital component of an internal combustion engine, playing a crucial role in controlling the flow of air, fuel, and exhaust gases, as well as housing essential components like valves and spark plugs. Its design and construction significantly impact an engine's performance, efficiency, and durability, making it a key area of focus for automotive manufacturers and engineers. From material selection and component arrangement to advanced manufacturing techniques and variable valve timing systems, the cylinder head continues to evolve, enabling the development of more powerful, efficient, and environmentally friendly engines.

FAQs

What is the purpose of the cylinder head?

The cylinder head seals the top of the engine cylinders and houses crucial components like valves, spark plugs, and fuel injectors. It regulates the flow of air, fuel, and exhaust gases in and out of the cylinders.

What are the main components found in a cylinder head?

The main components include the combustion chamber, intake and exhaust valves, intake and exhaust ports, spark plugs/fuel injectors, valve guides and seats, and cooling passages.

What are the different types of cylinder head designs?

The main types are flathead, overhead valve (OHV), and overhead camshaft (OHC) designs, each offering different performance and efficiency characteristics.

What materials are used for cylinder heads?

Cylinder heads are typically made from cast iron or aluminum alloys, with aluminum offering better heat dissipation and weight savings.

What is the role of the cylinder head gasket?

The cylinder head gasket seals the cylinder head to the engine block, preventing leaks of coolant, oil, and combustion gases.

How does the cylinder head contribute to engine cooling?

The cylinder head contains cooling passages that allow coolant to circulate and dissipate heat generated during the combustion process.

What are some common issues with cylinder heads?

Common issues include cracks due to overheating, warpage, valve and seat wear, and coolant or oil leaks.

Why is regular maintenance of the cylinder head important?

Regular maintenance helps identify and address issues like cracks, leaks, or worn components, preventing further damage and ensuring optimal engine performance.

How do cylinder heads differ between gasoline and diesel engines?

Diesel engine cylinder heads often accommodate prechambers or swirl chambers for combustion, resulting in higher thermal stresses and more complex cooling designs.

What are some latest advancements in cylinder head technology?

Recent advancements include lightweight materials, variable valve timing systems, integrated exhaust manifolds, and additive manufacturing techniques for optimized designs.

Bình luận (0)

Bài viết đề xuất

Coolant hoses are an indispensable part of a vehicle's cooling system, responsible for transporting coolant between the engine and radiator. These hoses must be able to withstand high temperatures, pressure, and exposure to various coolants and chemicals. This article explores the different types of coolant hoses, their materials, characteristics, and applications, providing a comprehensive understanding of this essential automotive component.

Semi trucks primarily use air brakes, which are different from the hydraulic brakes used in most passenger vehicles. Air brakes are the most common type of braking system in semi trucks, utilizing compressed air to apply pressure to the brake pads or shoes, creating friction against the brake drum or rotor to slow down or stop the vehicle. The compressed air is supplied by an engine-mounted compressor and stored in tanks until needed.

Integrated brake systems (IBS) represent a significant advancement in automotive braking technology, combining multiple braking functions into a single, compact unit. This innovative approach to braking offers numerous benefits, including improved safety, efficiency, and performance. In this article, we will explore the key features and advantages of integrated brake systems, their components and functionality, and their impact on the future of the automotive industry.

Bài viết liên quan

The internal combustion engine is a remarkable invention that has revolutionized transportation and industry.

A crankshaft is a critical component found in internal combustion engines, which are widely used in various applications, including automobiles, trucks, generators, and industrial machinery

Camshafts are a critical component in internal combustion engines, responsible for precisely controlling the opening and closing of the engine's intake and exhaust valves. This intricate coordination of valve movement is fundamental for an engine's performance, efficiency, and power output.

In the ever-evolving automotive industry, valves play a pivotal role in regulating and controlling the flow of various fluids, gases, and air-fuel mixtures. From engine components to braking systems, these mechanical marvels ensure efficient and reliable performance.

Spark plugs are essential components that play a crucial role in the operation of gasoline-powered internal combustion engines. They are responsible for igniting the air-fuel mixture within the engine's combustion chamber, initiating the combustion process that powers the vehicle

A timing belt, also known as a cambelt, is a critical component in an internal combustion engine that synchronizes the rotation of the crankshaft and camshaft(s).

An intake manifold plays a pivotal role in an internal combustion engine's performance by evenly distributing the air/fuel mixture to each cylinder. This comprehensive guide delves into the intricacies of this critical component, exploring its design, types, materials, performance modifications, installation, and maintenance aspects.

The exhaust manifold is a critical component that plays a pivotal role in optimizing an engine's performance. This comprehensive guide delves into the intricate details of exhaust manifolds, exploring their design, function, and impact on engine efficiency.